combine harvester

A combine harvester and machine body technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of the posture change of the conveying cylinder, the displacement of the discharge position, the unstable posture of the conveying cylinder, and the loss of grains, etc., to achieve support Effects of increased rigidity, smooth holding, and reliable holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

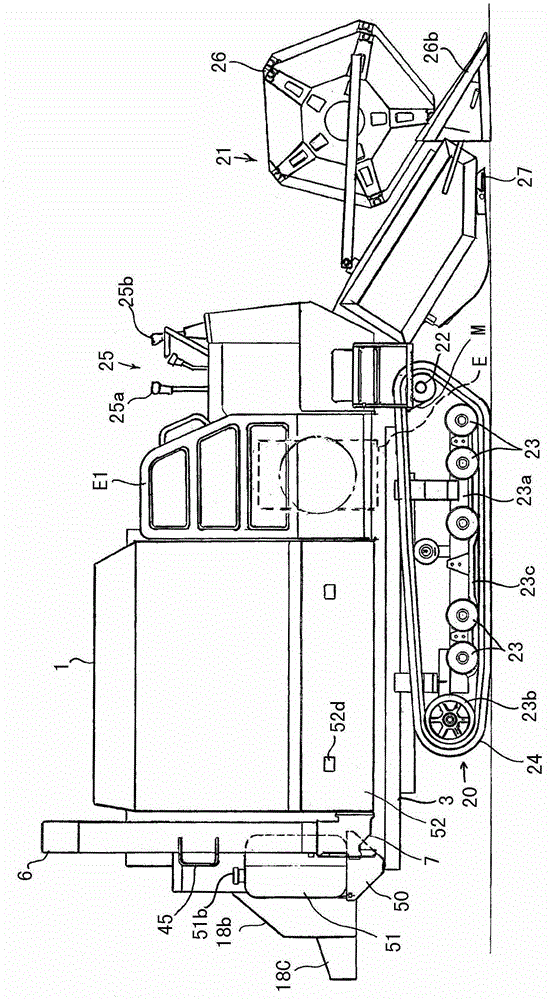

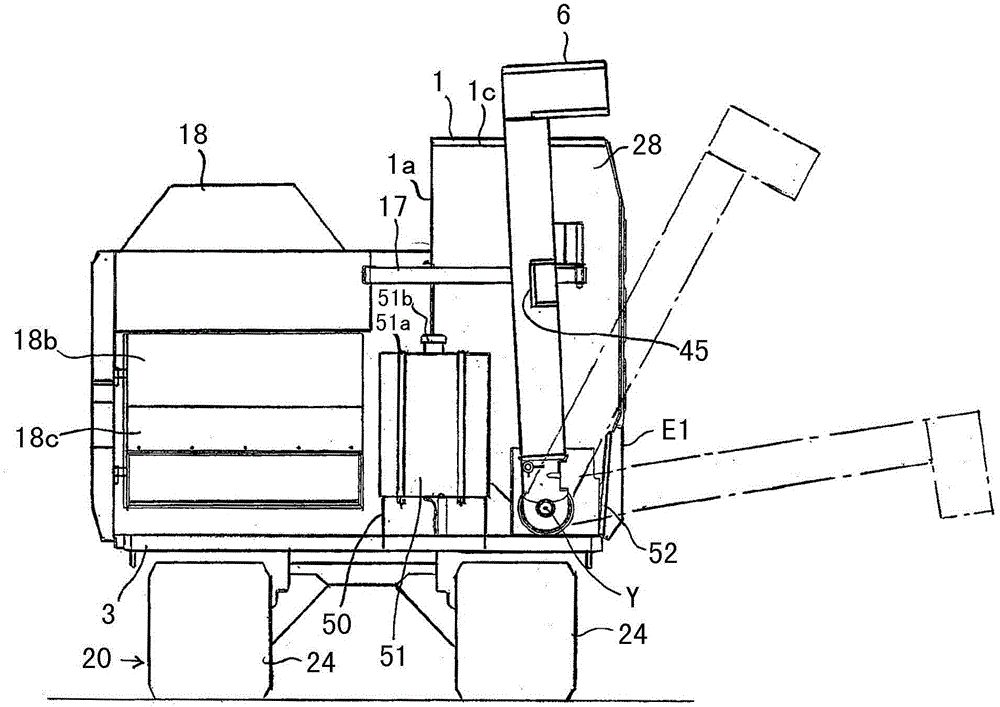

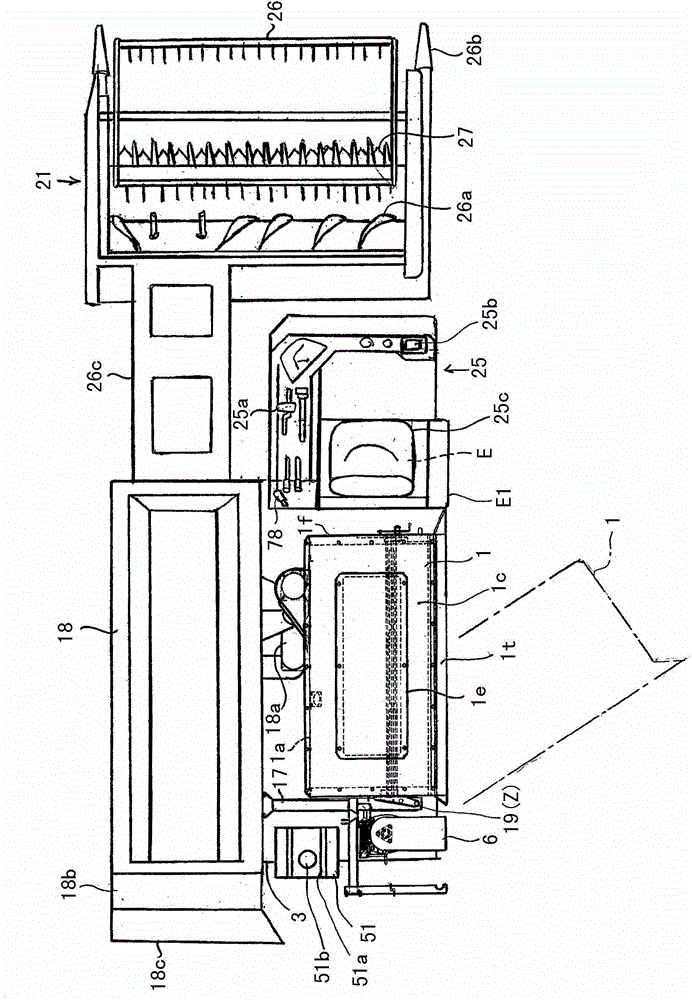

[0065] Embodiments of the present invention will be described by taking an ordinary combine harvester as an example.

[0066] (body structure)

[0067] Such as Figure 1 ~ Figure 3 As shown, the combine harvesting mechanism becomes: a traveling device 20 is provided below the body frame 3, a threshing device 18 is mounted on the upper left side of the body frame 3, and grains are mounted on the upper right side of the body frame 3. The storage device 1 and the conveying cylinder 6 for grain discharge are equipped with an electronic governor type or a common rail fuel injection engine E at the front side of the grain storage device 1 on the body frame 3, and the running device The front position of 20 is provided with the harvesting device 21 that can carry out lifting adjustment freely.

[0068] (Structure of the driving part, running gear and control part)

[0069] Such as figure 1 , image 3 As shown, the engine E is covered by a freely openable and closable engine cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com