Turntable mechanism

A turntable mechanism, a technology of rotating discs, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., to achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

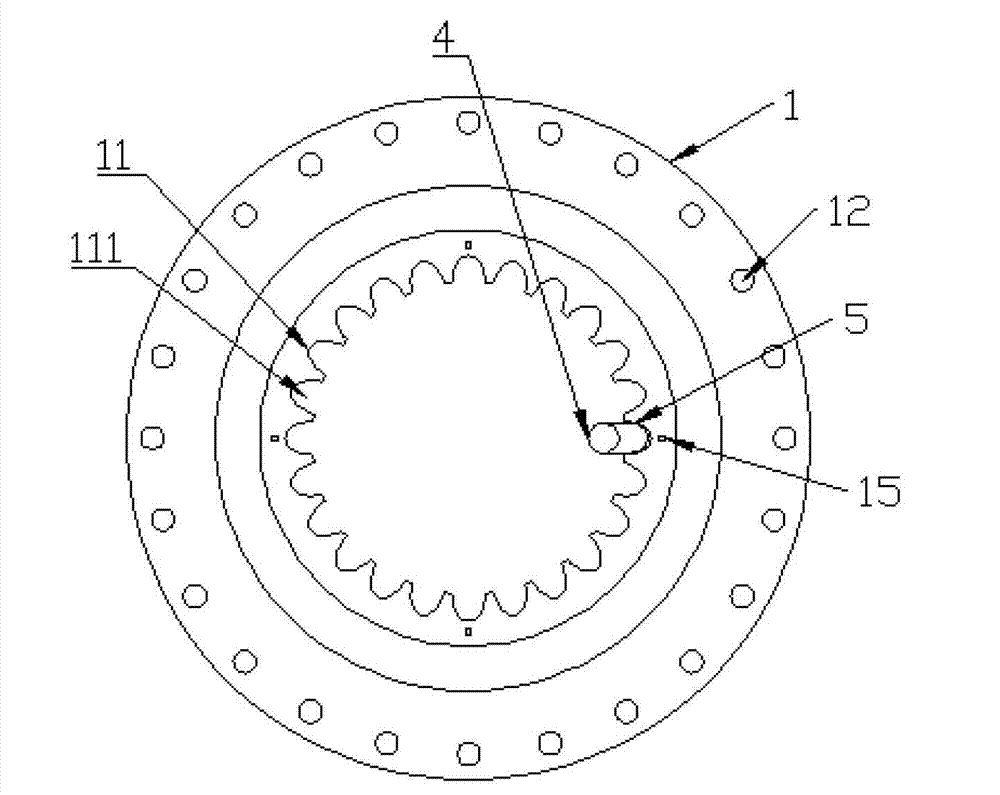

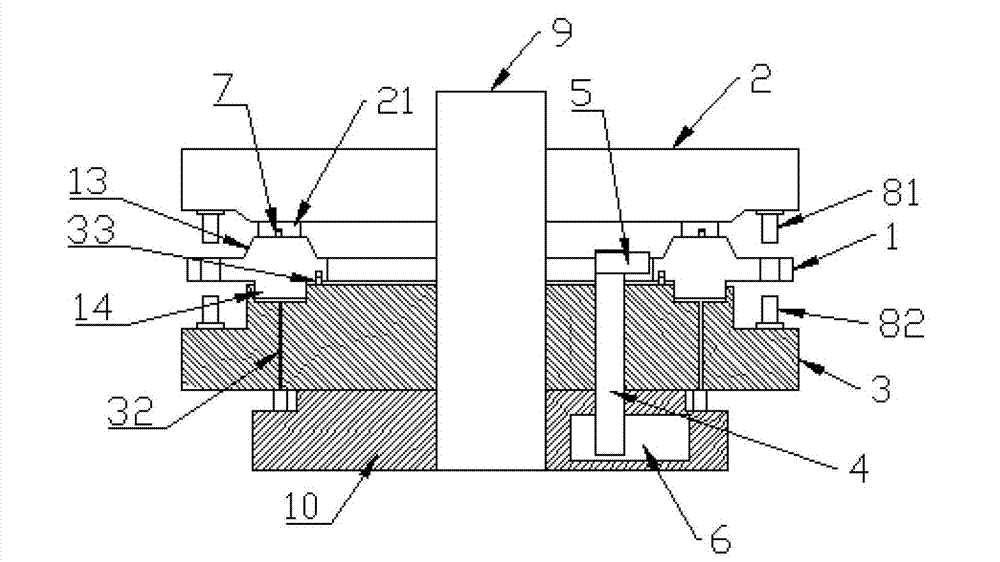

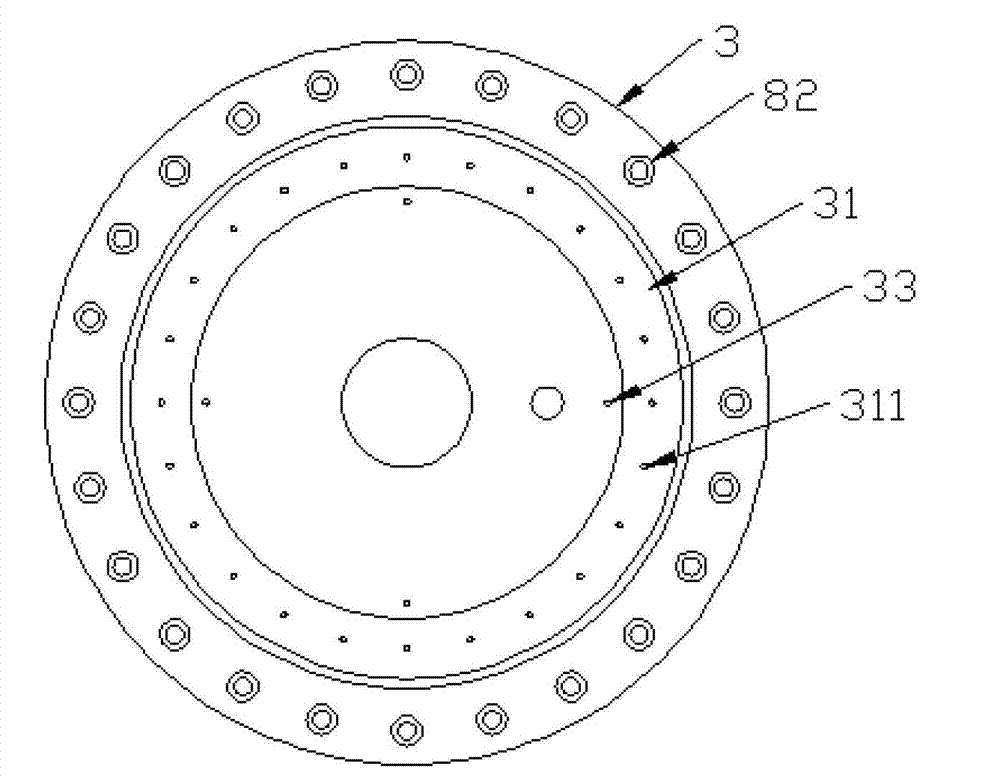

[0022] Embodiment: a turntable mechanism, comprising a rotating disk 1, an upper bracket 2 positioned above the rotating disk, a lower bracket 3 positioned below the rotating disk, a rotating lever 4, an eccentric wheel 5 fixed to the upper end of the rotating lever and A driving device 6 connected to the lower end of the rotating lever and driving the rotating lever to rotate around its own axis, a circle of grooves 11 is provided in the middle of the rotating disc, and the circle of grooves 11 is formed by a plurality of arc-shaped grooves. The monomers 111 are arranged and connected along the circumferential direction. The eccentric wheel 5 is located in the groove 11 and cooperates with the arc groove monomer 111. The edge of the rotating disk 1 is provided with a circle of processing The said circle of processing positions is composed of several processing positions 12 arranged at intervals along the circumferential direction, and the number of said processing positions 12...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap