Composite double-face copper foil substrate and manufacturing method thereof

A double-sided copper foil, manufacturing method technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the high cost of the two-layer flexible cover film and poor appearance, thinning and dimensional stability, The length cannot be made long, etc., to achieve excellent dimensional stability and bending resistance, improve yield, and avoid the effects of high-temperature lamination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

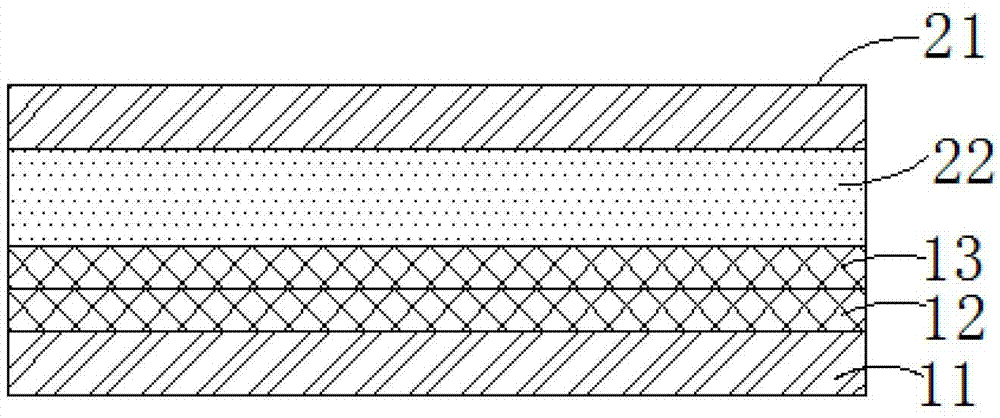

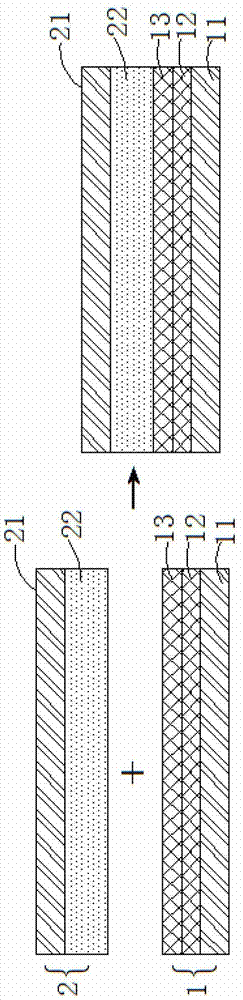

[0020] Embodiment: A composite double-sided copper foil substrate, which is composed of a single-sided copper-clad laminate without glue 1 and a copper-clad laminate with glue 2. The single-sided copper-clad laminate without glue 1 is formed by a layer of copper foil 11 and a One surface is made of an insulating base layer, wherein the insulating base layer is composed of a layer of first insulating base film 12 and a layer of second insulating base film 13, and the adhesive copper foil plate is composed of another copper foil 21 and coated on The second insulating base film 13 and the insulating adhesive layer 22 are arranged adjacent to each other.

[0021] Wherein, the first insulating base film 12 is a thermosetting polyimide film (PI), a polyethylene terephthalate film (PET), a polynaphthyl ester film (PEN) and a liquid crystal polymer film ( PLC), and the thickness of the first insulating base film 12 is 7~100um; the second insulating base film 13 is a thermoplastic poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com