Ship provided with sinking prevention tanks and manufacturing method thereof

A technology for ships and hulls, which is applied to ships equipped with anti-sinking tanks and their manufacturing fields, can solve problems such as preventing sinking, unsightly appearance of ships, etc., achieves simple manufacturing processes, reduces personal injury and property losses, and saves manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings. When understanding the terms or words used in this specification and claims, it should be based on the principle that the inventor has the ability to define the relevant terms and concepts in the most suitable way to describe the present invention, and understand them as meanings and concepts that conform to the technical idea of the present invention.

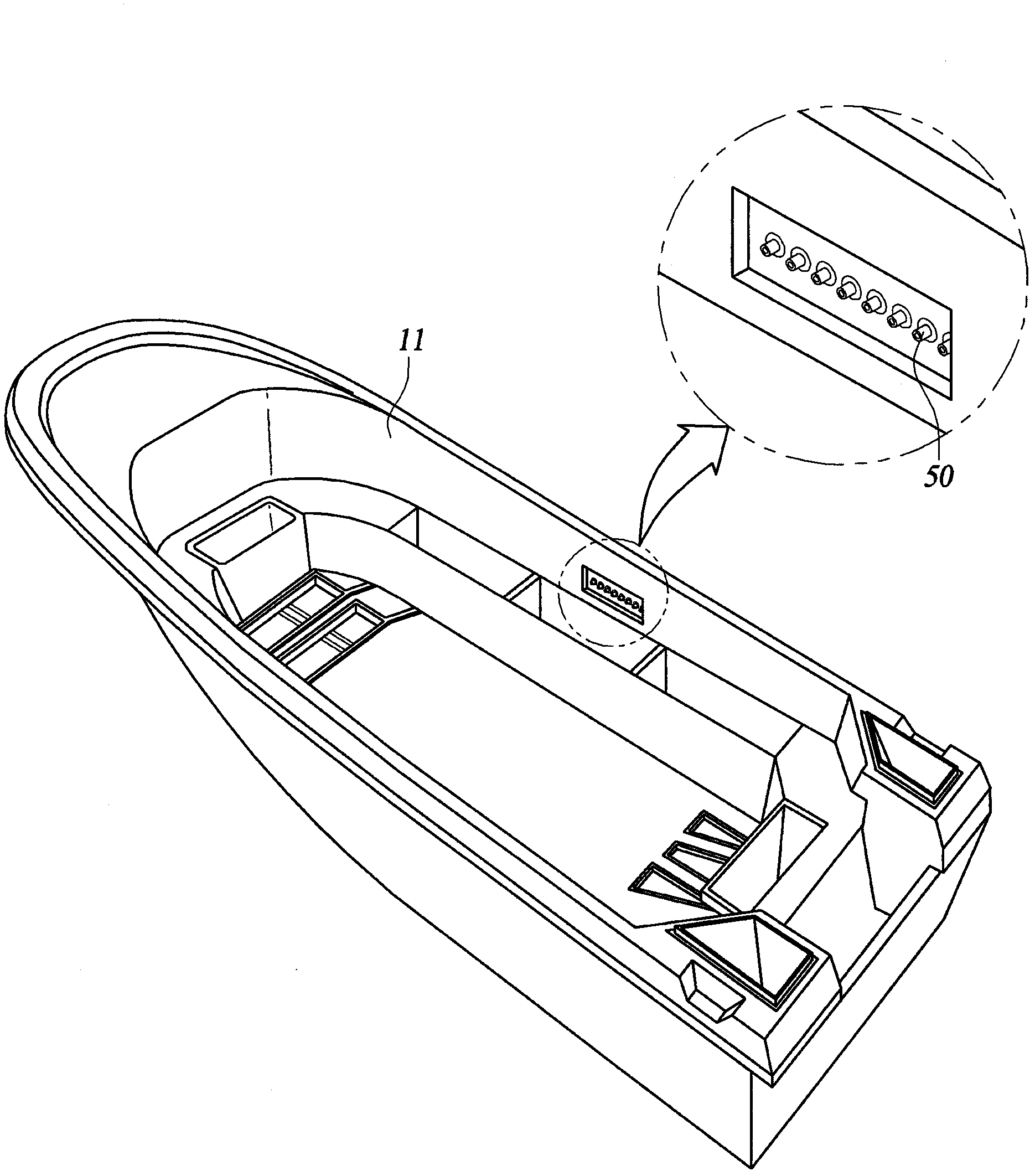

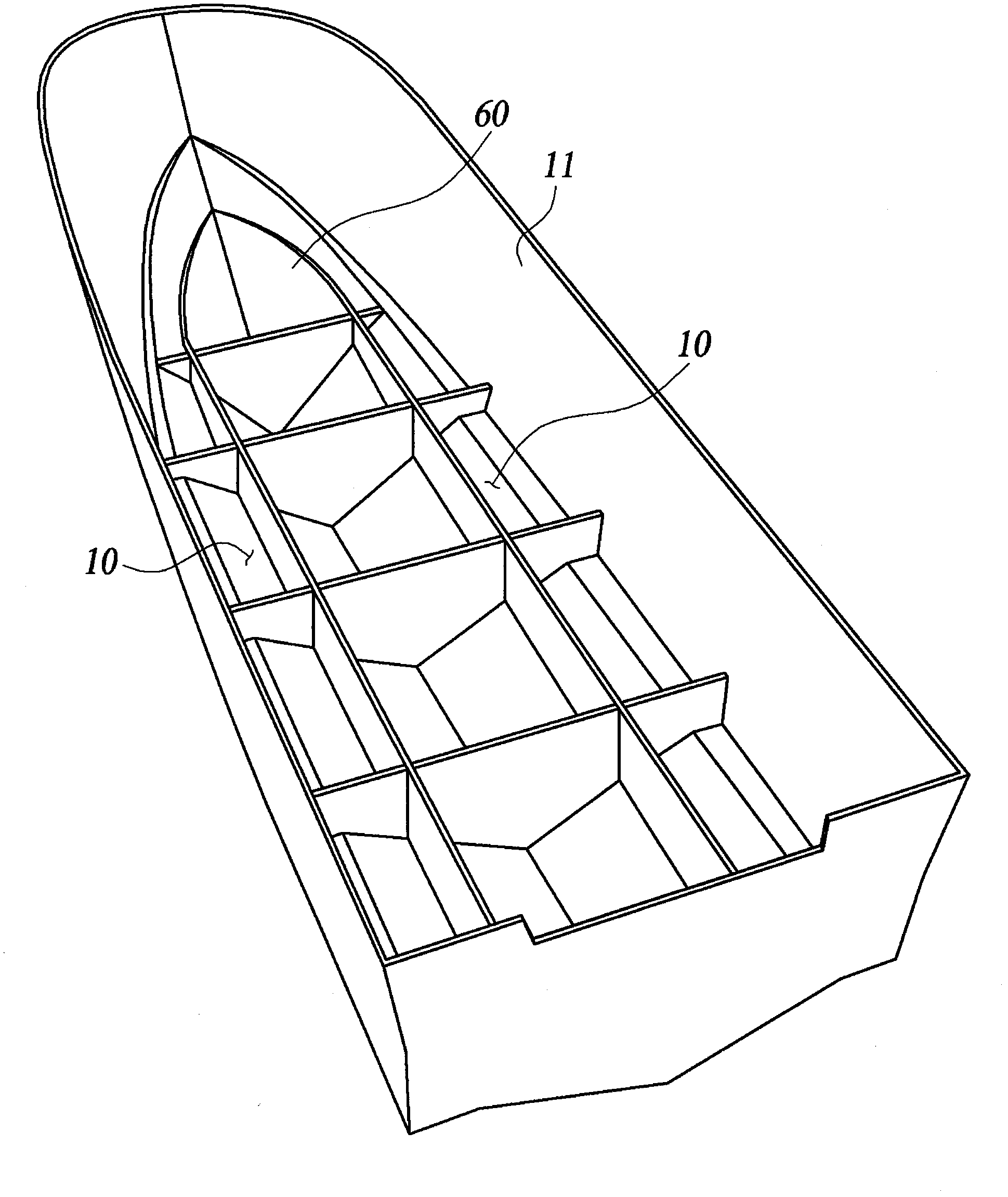

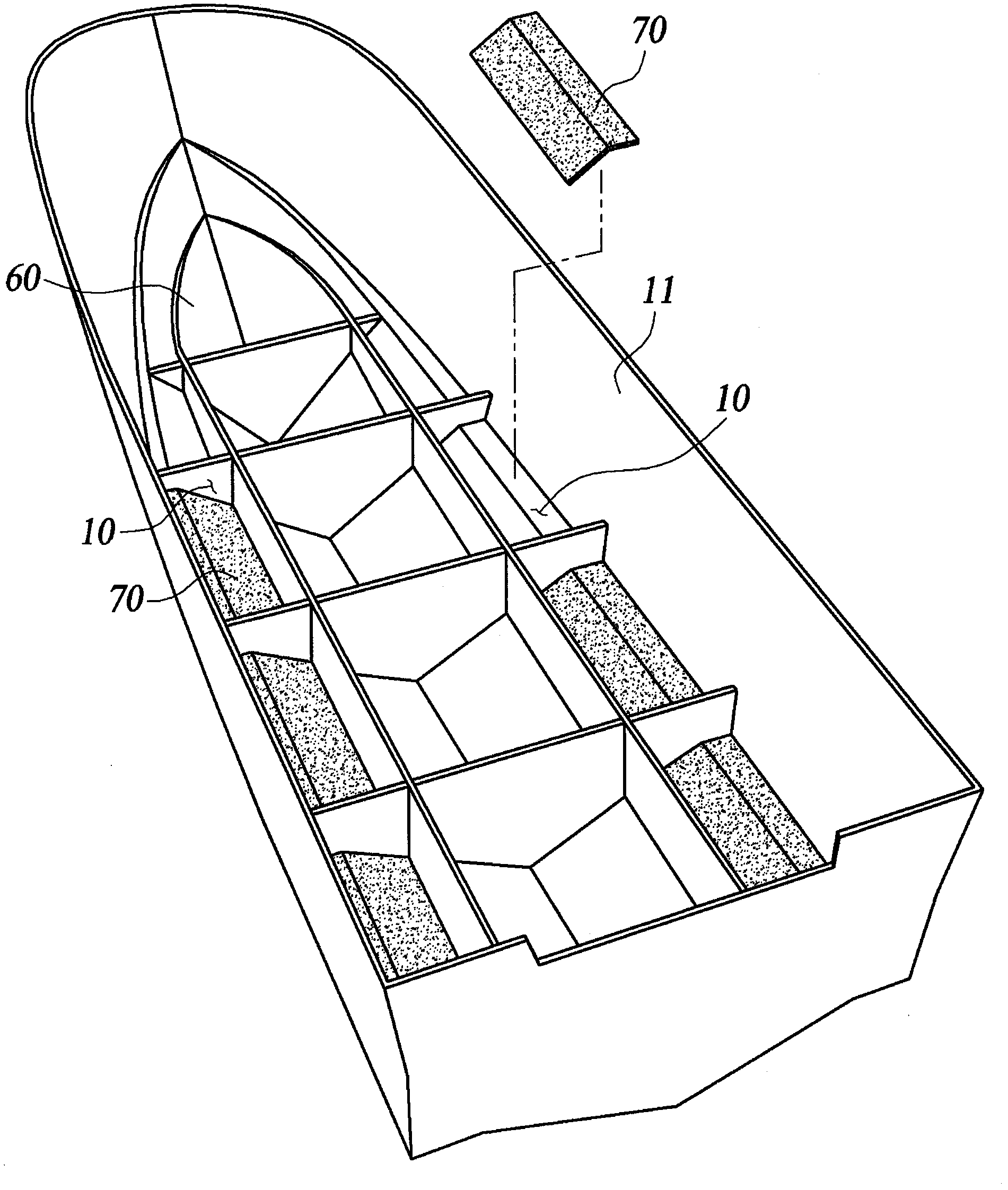

[0029] As shown in the figure, the ship equipped with the anti-sinking tank of the present invention includes tank containing parts 10 equipped on the port and starboard sides of the hull 11 bottom plate of the ship; The anti-sinking tank 20 of the part 21; respectively seal the barrier wall 30 on the top of the tank housing part 10 with the above-mentioned anti-sinking tank 20; be respectively connected to the gas supply pipe 40 of the inflatable part 21 on the above-mentioned an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com