Method for preparing carbon nanometer tube macroscopic body in self-assembly way

A technology of carbon nanotubes and macroscopic bodies, which is applied in the field of self-assembly of highly dispersed short carbon nanotubes in neutral aqueous solution to prepare ribbon-shaped macroscopic bodies, which can solve the problem of danger, high requirements for equipment, and strong corrosiveness of chlorosulfonic acid. and other issues, to achieve the effect of safe assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

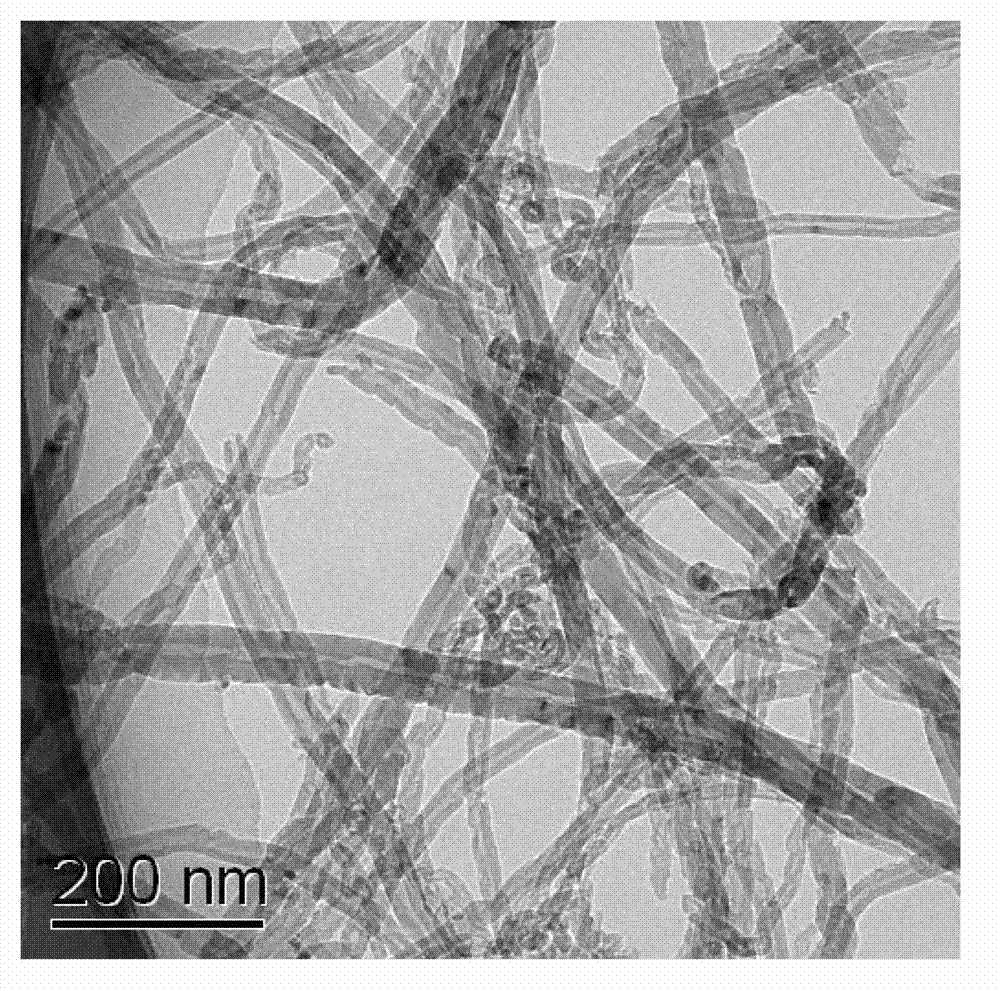

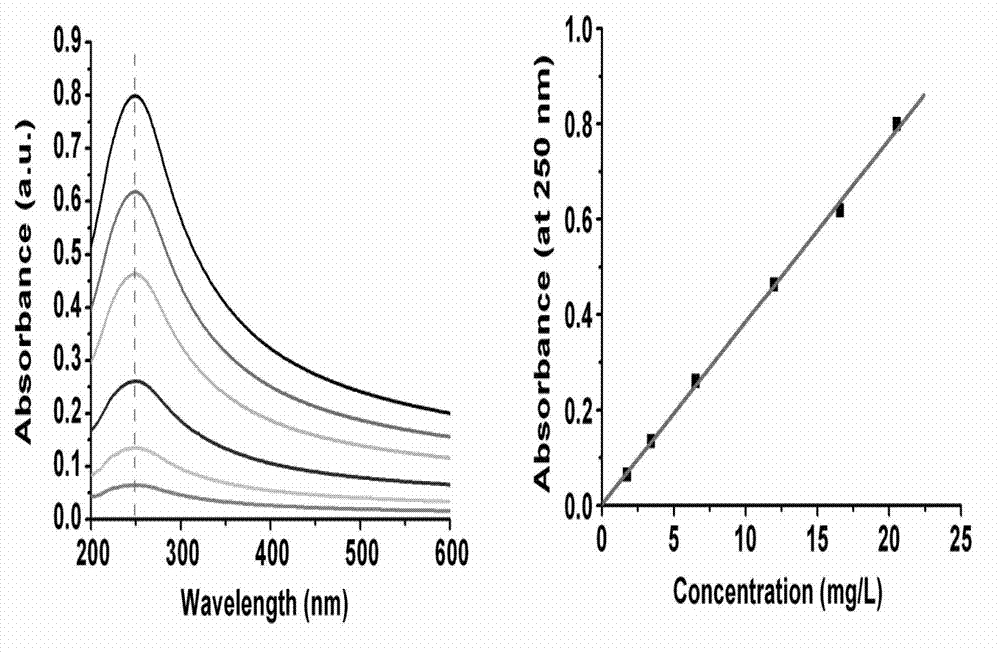

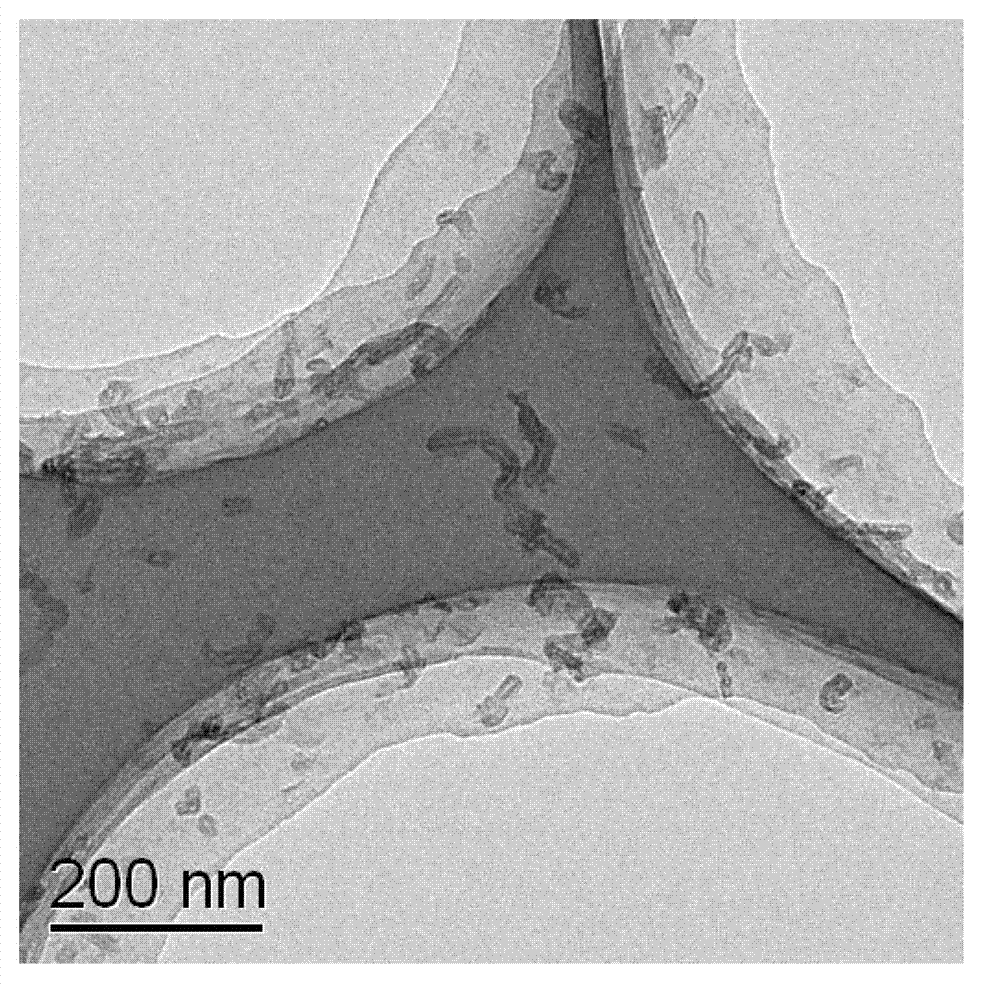

[0018] The carbon nanotubes to be purchased (purity about 95%, source: Chengdu Organic Chemical Co., Ltd., figure 1 ) 0.5 g and 1.5 g of potassium permanganate solids were sequentially added to a beaker containing 15 ml of concentrated sulfuric acid (98%), stirred well, then placed in a constant temperature water bath at 50°C for 3 hours, and left to cool After reaching room temperature, dilute with about 100ml of deionized water and keep stirring, then add about 10ml of 30% hydrogen peroxide solution, stir and react for 15 minutes, then filter with a microporous membrane. The obtained black solid is directly poured into 100ml of 4% dilute hydrochloric acid, stirred and washed, then filtered with a microporous membrane, and washed with deionized water, and the obtained black solid is poured into 200ml of deionized water and fully stirred. Pour into 4 centrifuge tubes on average and centrifuge at 14000 rpm for 30 minutes. After layering, pour off the supernatant, and continue t...

Embodiment 2

[0023] The preparation process of the neutral aqueous solution of short carbon nanotubes is the same as that in Example 1.

[0024] Take 10ml of short carbon nanotube neutral aqueous solution and pour it into a 25ml beaker, and place it in a constant temperature blast drying oven at 30°C to dry for 24 hours, and self-assembly is also obtained to obtain a length of about several centimeters and a cross-sectional size of microns Level carbon nanotube ribbon macro body.

[0025] The carbon nanotube ribbons obtained above were laid flat in a quartz boat and placed in the quartz tube of a tube furnace, raised to 700°C at a heating rate of 20°C / min, kept at this temperature for 3 hours, and then cooled naturally to room temperature, and at the same time pass through the flowing nitrogen protection during the whole process. The obtained annealed carbon nanotube ribbon still maintains the original appearance, and the electrical conductivity test shows that the carbon nanotube ribbon ...

Embodiment 3

[0027] The carbon nanotubes to be purchased (purity about 95%, source: Chengdu Organic Chemical Co., Ltd., figure 1 ) 0.5 grams and 0.5 grams of potassium permanganate solids were added to a beaker filled with 15ml of concentrated sulfuric acid (98%) in turn, and after stirring well, they were placed in a constant temperature water bath at 50°C for 3 hours and left to cool After reaching room temperature, dilute with about 100ml of deionized water and keep stirring, then add about 10ml of 30% hydrogen peroxide solution, stir and react for 15 minutes, then filter with a microporous membrane. The obtained black solid is directly poured into 100ml of 4% dilute hydrochloric acid, stirred and washed, then filtered with a microporous membrane, and washed with deionized water, and the obtained black solid is poured into 200ml of deionized water and fully stirred. Pour into 4 centrifuge tubes on average and centrifuge at 14000 rpm for 30 minutes. After layering, pour off the supernata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap