Encapsulation gel breaker and preparation method of encapsulation gel breaker

A technology of gel breaker and encapsulation, which is applied in the field of encapsulated gel breaker and its preparation, can solve problems such as failure to break the gel, and achieve the effect of improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

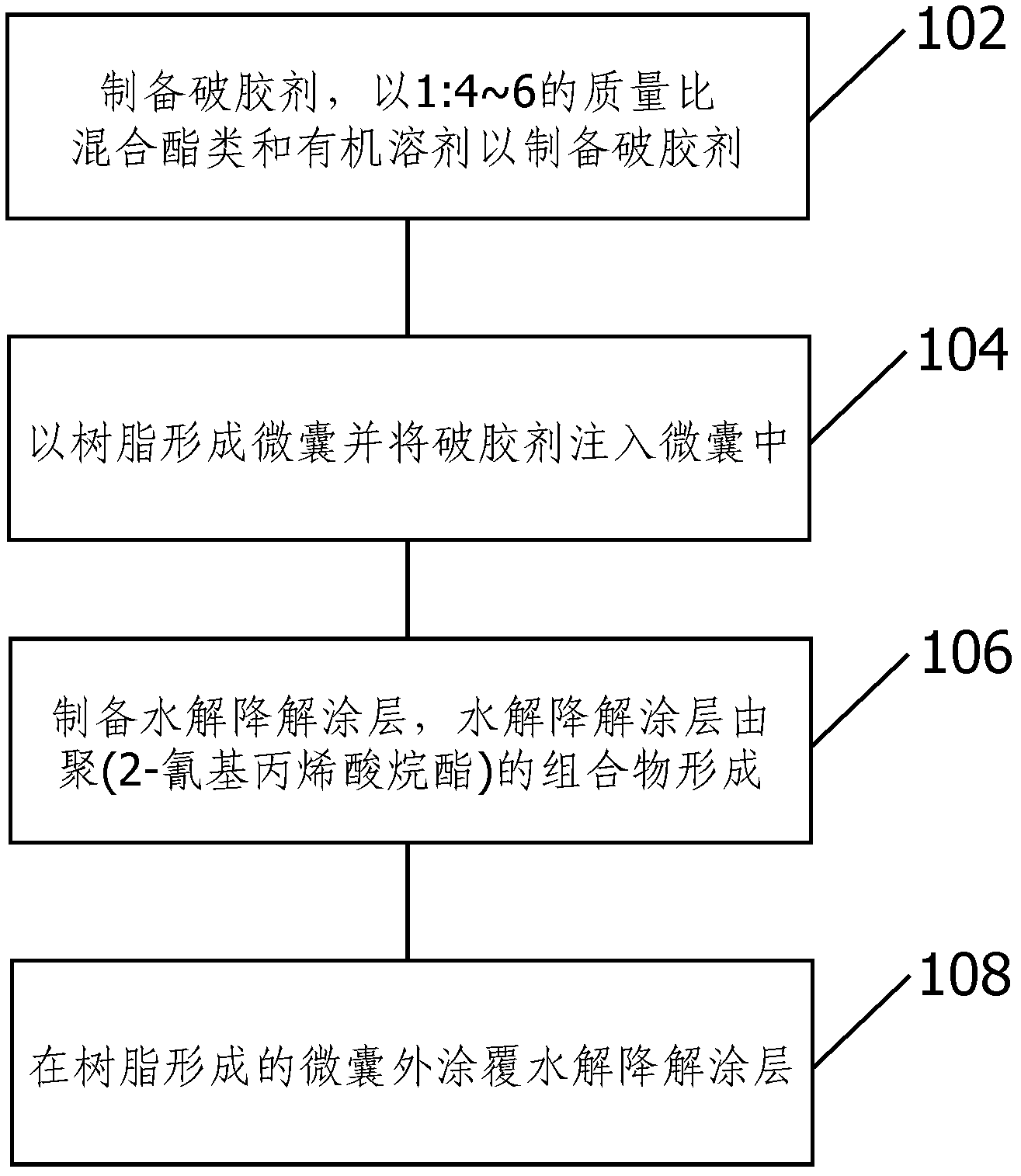

[0020] refer to figure 1 As shown, the present invention discloses a preparation method of encapsulated breaker, the method comprises the following steps:

[0021] 102. Prepare a gel breaker by mixing esters and organic solvents in a mass ratio of 1:4-6 to prepare the gel breaker. In one embodiment, the ester used to prepare the breaker includes one or a combination of methyl formate, ethyl formate or dimethyl malonate, and the organic solvent used to prepare the breaker is petroleum ether.

[0022] 104. Forming microcapsules with a resin and injecting a breaker into the microcapsules.

[0023] 106. Preparation of a hydrolytically degradable coating formed from a composition of poly(2-alkyl cyanoacrylate). In one embodiment, the hydrolytically degradable coating is a composition comprising at least 50% by weight poly(2-alkyl cyanoacrylate). In another embodiment, the hydrolytically degradable coating comprises a composition of at least 80% by weight poly(2-alkyl cyanoacryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com