Metal drawing oil

A technology for stretching oil and metal, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of increased difficulty in cleaning procedures, low product qualification rate, uneven stretching, etc., and achieves improved quality and processing power. Good thermal performance and heat-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

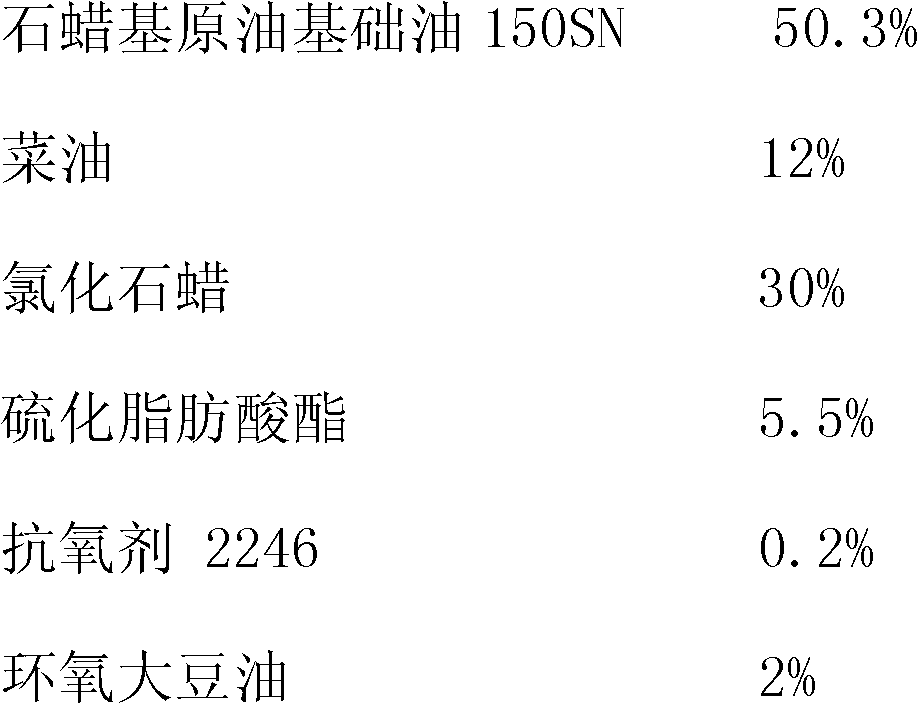

Embodiment example 1

[0026]

[0027] Implementation example 1 is suitable for general stretching purposes of steel, stainless steel and heat-resistant steel.

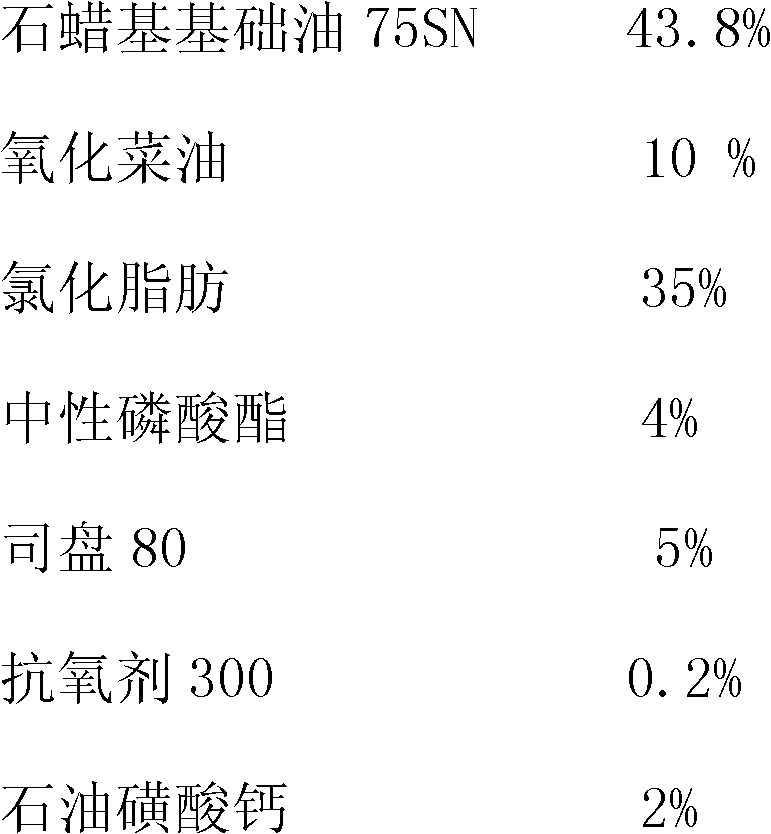

Embodiment example 2

[0029]

[0030] Example 2: It is suitable as an easy-to-clean stretching oil for steel, stainless steel and heat-resistant steel

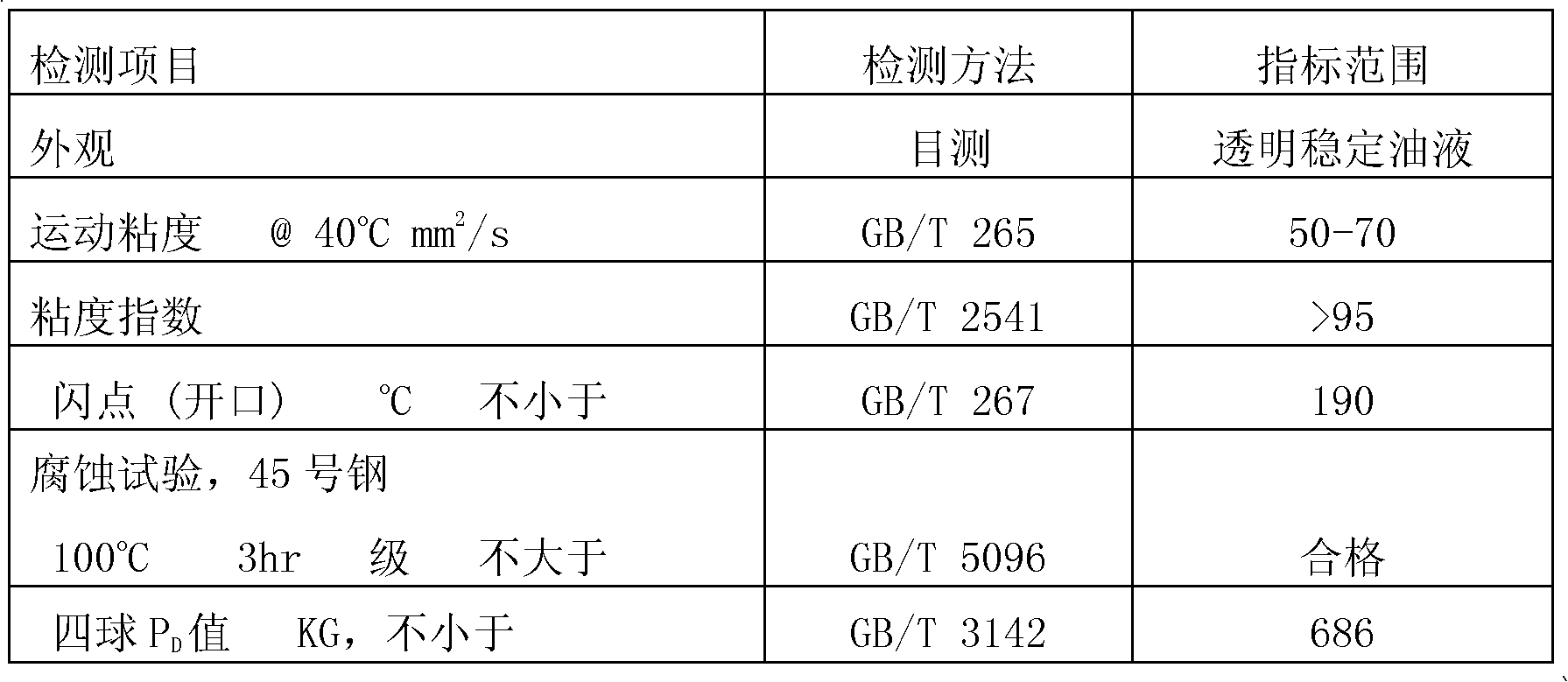

[0031] Table 1 is the performance test data of implementation case 1:

[0032] Table 1:

[0033]

[0034] The formula of embodiment 3-10 is as shown in table 2:

[0035] Table 2, % by weight, based on the total weight of the cleaning agent.

[0036] Example

oily agent

Extreme Pressure Additives

Surfactant

corrosion inhibitor

3

11%

22%

0.1%

0%

1%

65.9%

[0037] 4

8%

30%

0.2%

7.6%

2%

59.8%

5

16%

38%

0.5%

0%

1%

44.5%

6

23%

18%

0.4%

0%

0%

52.8%

7

5%

34%

0%

4%

2.5%

54.5%

8

14%

27%

0.5%

2.5%

0.5%

55.5%

9

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com