Weaving method for truncated cone-shaped fabric

A truncated cone, fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problem of not involving two yarn adding technologies, and achieve the effect of compact structure, fast forming speed and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Fabric thickness <5mm) Weaving of thin-walled frustum fabric:

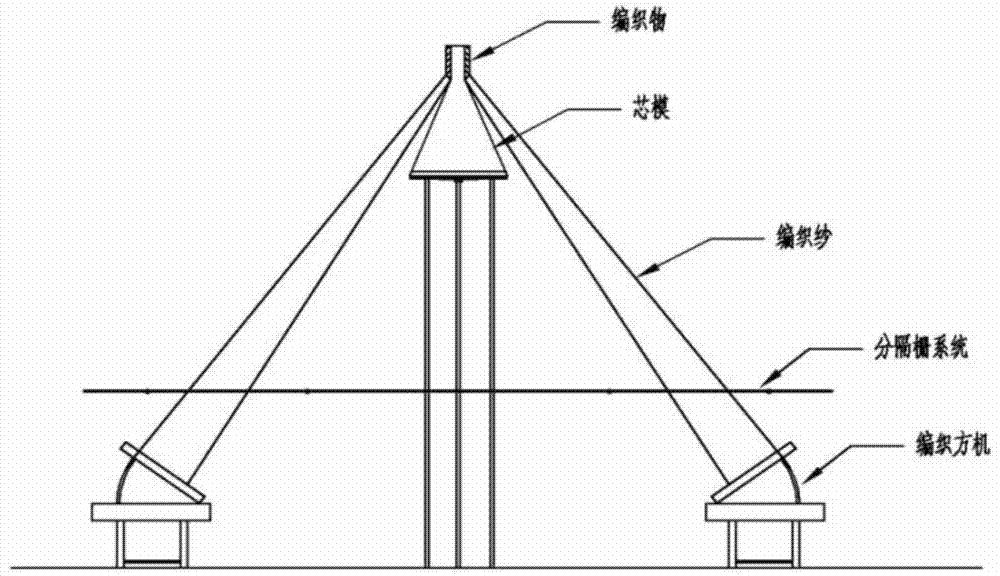

[0029] The warp yarn is 190Tex quartz fiber × 3 strands, the weft yarn is 190Tex quartz fiber × 6 strands, the thickness of the truncated cone fabric is 3mm, the cone angle at the top of the mandrel is 31.6°, the outer diameter of the small end of the fabric is Φ (22.8±1) mm, the largest The outer diameter of the end is Φ (447.7±1) mm, the number of warp layers is designed to be 4 layers, the warp density of the fabric is 7 threads / cm, the weft density is 3 threads / cm, the cross section of the fabric is a conical surface, and the fabric structure is 2.5 D layer corner interlocking structure, the fabric shape is figure 1 The shape of the core mold, the specific weaving steps are as follows:

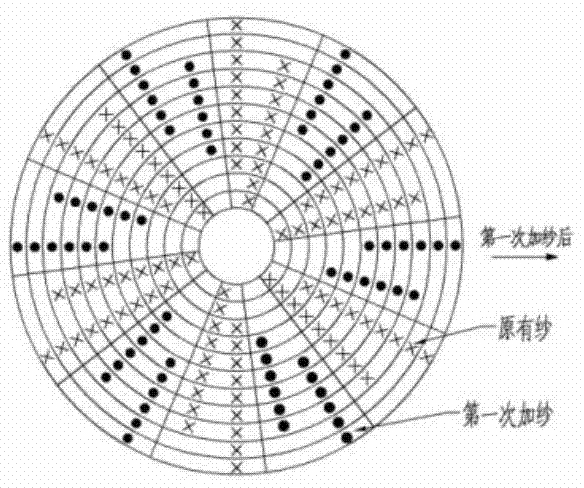

[0030] 1) Initial yarn arrangement. The warp yarns are initially arranged in 4 layers and 50 rows of warp yarns.

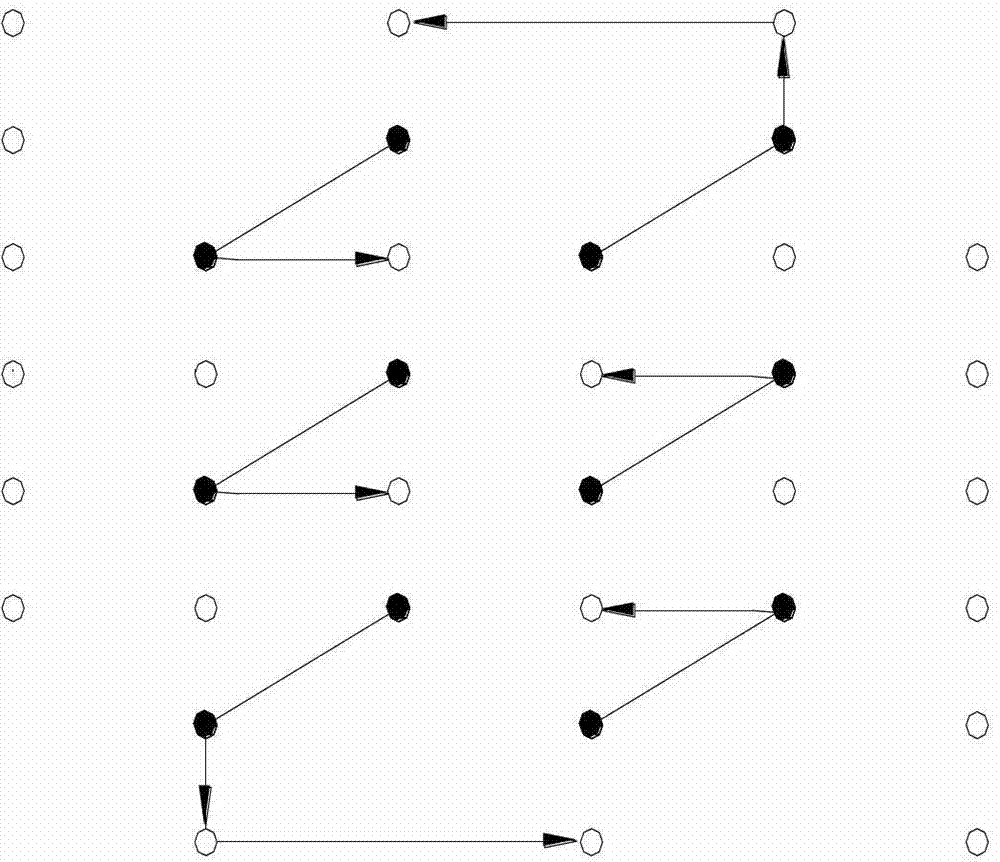

[0031] 2) Open mouth movement. The heald lifting device controls the relative movement of the front ...

Embodiment 2

[0039] Weaving of thick-walled frustum fabrics with fabric thickness ≥ 5mm:

[0040] The warp yarn is 190Tex quartz fiber × 3 strands, the weft yarn is 190Tex quartz fiber × 6 strands, the thickness of the truncated cone fabric is 10mm, the cone angle at the top of the mandrel is 31.6°, the outer diameter of the small end of the fabric is Φ (36.8±1) mm, the largest The outer diameter of the end is Φ (461.7±1) mm, the number of warp layers is designed to be 12 layers, the warp density of the fabric is 7 threads / cm, the weft density is 3 threads / cm, the cross section of the fabric is a conical surface, and the fabric structure is 2.5D Layered corner interlocking structure, the shape of the fabric is figure 1 The shape of the core mold, the specific weaving steps are as follows:

[0041] 1) Initial yarn arrangement. The warp yarns are initially arranged in 12 layers and 82 rows of warp yarns.

[0042] 2) Open mouth movement. The heald lifting device controls the relative move...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com