Tunnel drainage structure applicable to water-rich strata under unsymmetrical pressure and construction method thereof

A technology for tunnel drainage and water-rich strata, which is applied in the directions of drainage, earthwork drilling, safety devices, etc., can solve problems such as difficulty in effectively increasing the strength and stability of surrounding rock mass, difficulty in forming cementitious bodies, and inability to effectively eliminate them. Achieve the effect of improving cohesion and internal friction angle, increasing cohesion and internal friction angle, and preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

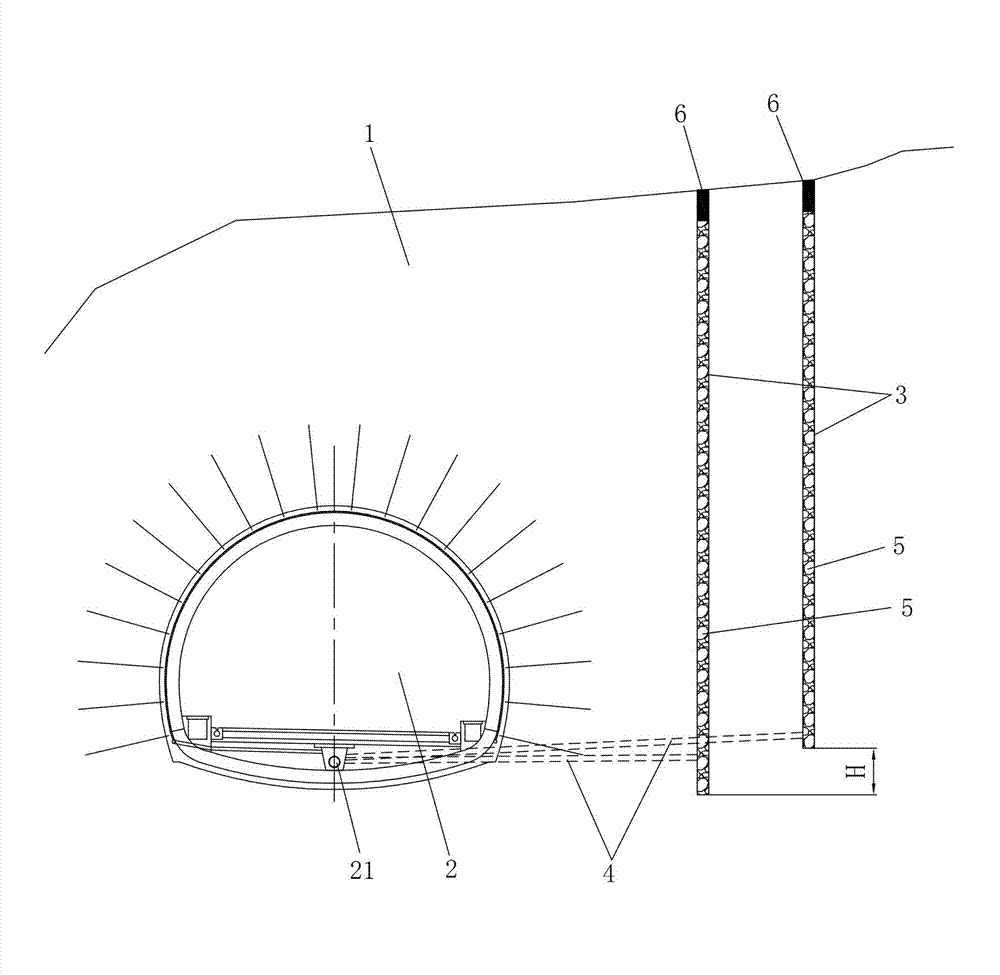

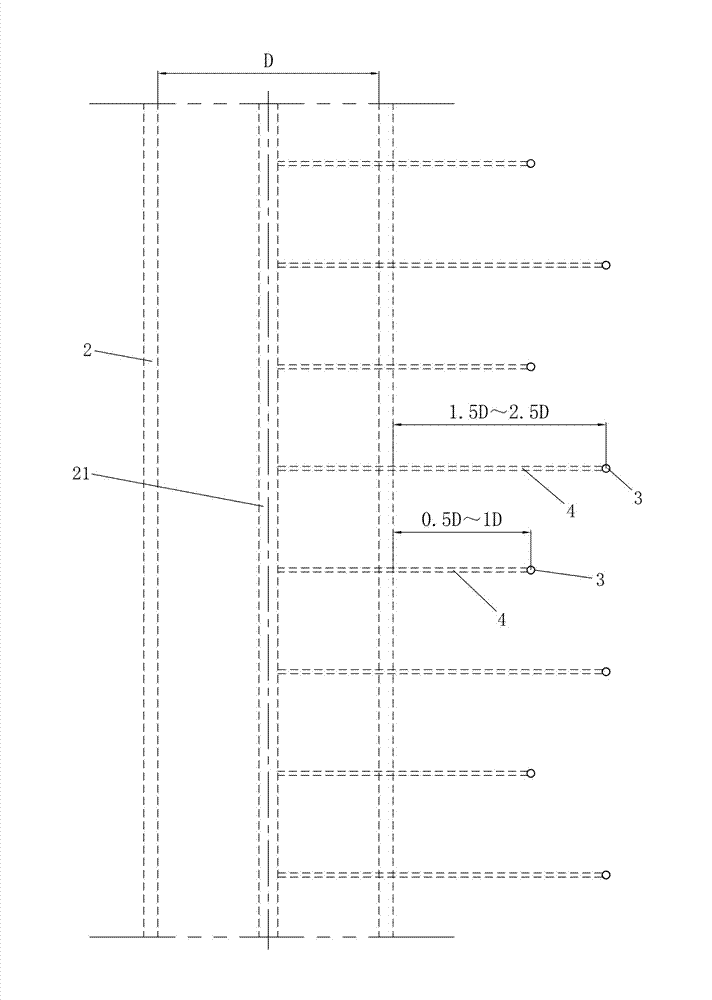

[0023] Such as figure 1 with figure 2 As shown, the present invention is applicable to the first embodiment of the tunnel drainage structure in the biased water-rich stratum. The tunnel drainage structure includes a tunnel body 2 located in the stratum 1, and an opening A plurality of vertical water collection wells 3 are dug, and a drainage channel 4 for draining water in the water collection wells 3 to the tunnel body 2 is provided between each water collection well 3 and the tunnel body 2 . By draining the water in the water collection well 3 for dewatering at the well point, the groundwater level of the formation 1 around the tunnel body 2 can be lowered, the cohesion and internal friction angle of the surrounding rock mass can be increased and improved, and the self-bearing capacity of the surrounding rock mass can be improved. capacity, during construction, before the excavation of the tunnel body 2, set up the water collection well 3, and then discharge the water in t...

Embodiment 2

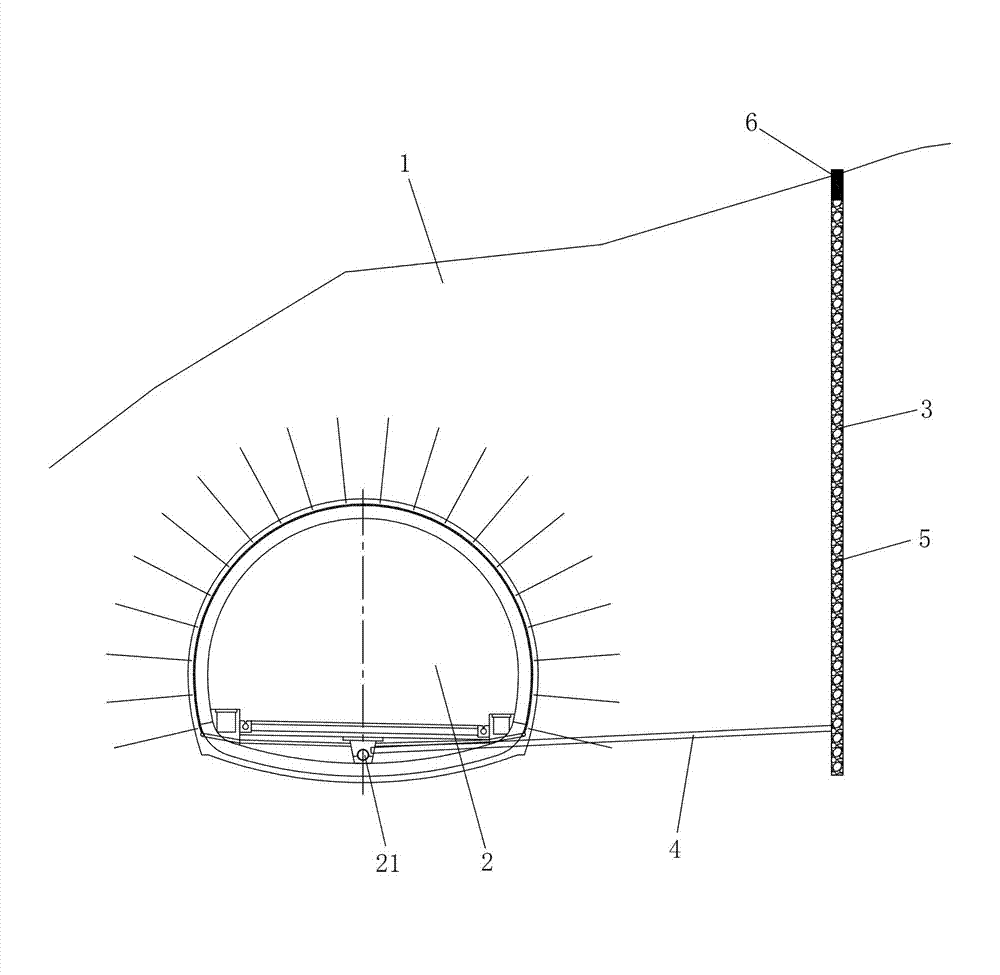

[0033] image 3 It shows the second embodiment of the tunnel drainage structure applicable to biased water-rich formations of the present invention. This embodiment is basically the same as Embodiment 1, except that the plurality of water collection wells 3 in this embodiment are only arranged in a row . The tunnel drainage structure of this embodiment is constructed with reference to the construction method of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com