Cam type brake mechanism

A braking mechanism and cam-type technology, applied in the direction of brake types, automatic brakes, mechanical equipment, etc., can solve the problems of insufficient braking, loss of braking mechanism, etc., and achieve improved efficiency, compact structure, and soft braking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

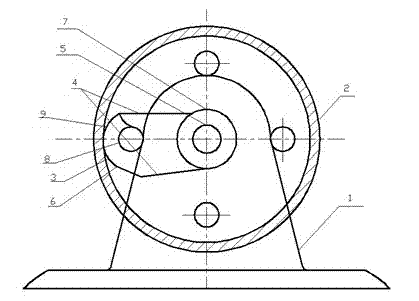

[0008] Such as figure 1 As shown, the cam-type braking mechanism of the present invention includes a frame 1, a brake wheel 2, a cam 3 and a steel plate spring 4, and the brake wheel 2 is hinged with the frame 1 through a rotating shaft 5, and the rotating shaft 5 is fixedly connected with The shaft sleeve 7 and the cam 3 are hinged between the shaft sleeve 7 and the inner wall of the brake wheel 2 through the camshaft 8. The cam 3 has a sliding end 9 and a braking end 6, and the sliding end 9 of the cam 3 is slidably connected with the inner wall of the braking wheel 2. , when the rotation direction of the brake wheel 2 is opposite to the direction of the brake end 6 of the cam 3, the brake end 6 of the cam 3 brakes the brake wheel 2, and the brake end 6 of the cam 3 is provided with a leaf spring 4 and a shaft Set of 7 connections.

[0009] When the direction of the braking end 6 of the cam 3 is counterclockwise, when the braking wheel 2 rotates counterclockwise, due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com