Copper-less and asbestos-free organic friction materials and products

A friction material and asbestos-free technology, applied in friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve problems such as friction coefficient driving accidents, friction coefficient reduction, etc., to reduce aggressiveness, improve impact toughness, and increase brake wear volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

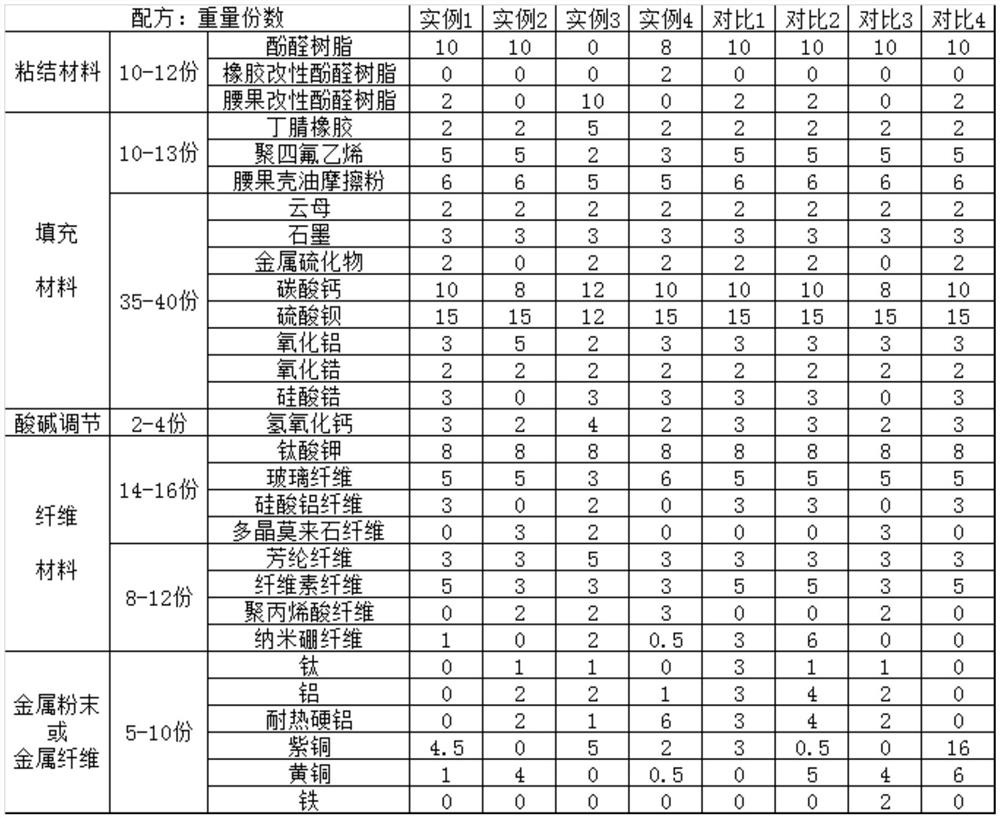

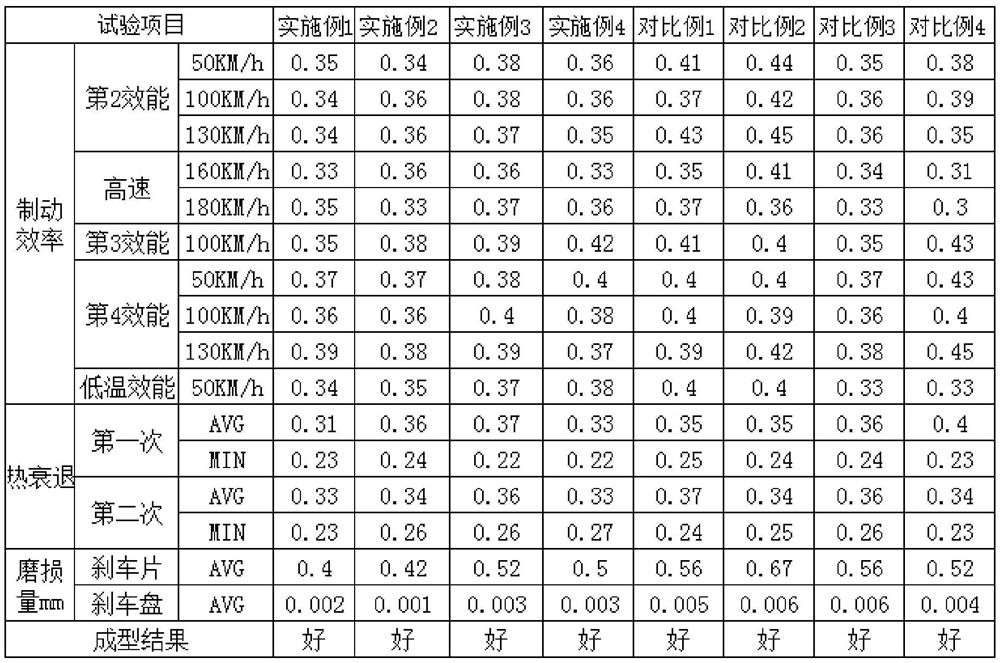

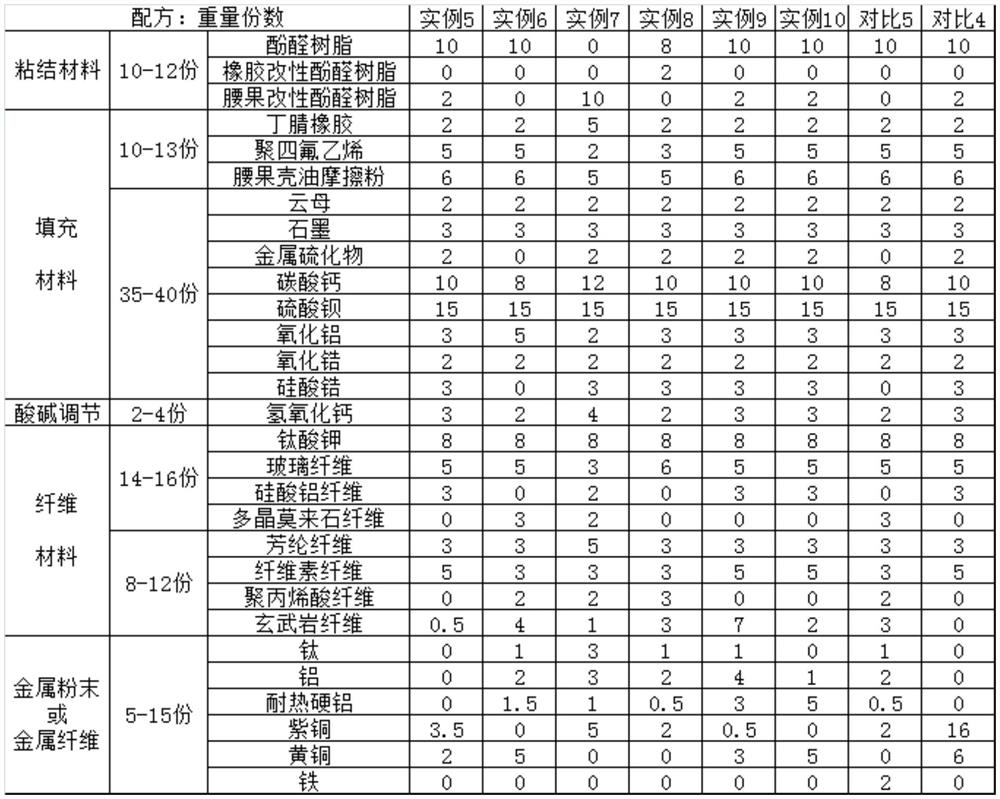

[0016] The invention provides an asbestos-free organic friction product, which includes a base material, an adhesive layer and a friction layer made of a copper-less and asbestos-free organic friction material. The copper-less and asbestos-free organic friction material is composed of the following components in parts by weight : 10-15 parts of bonding material, 45-55 parts of filling material, 20-30 parts of fiber material, 2-4 parts of acid-base adjustment material, 5-15 parts of metal fiber or metal powder, of which the fiber material contains 0-2.5 0.5-10 parts of nano-boron fiber or 0.5-10 parts of basalt fiber, metal fiber or metal powder is one or more combinations of titanium, aluminum, heat-resistant duralumin, red copper and brass, and the copper content is less than 5% .

[0017] Wherein, the bonding material is phenolic resin or modified phenolic resin, and the modified phenolic resin is preferably cashew nut shell oil modified phenolic resin or rubber modified phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com