Asbestos-free organic friction materials and products for transmission and braking with less copper

A friction material and asbestos-free technology, which is applied to friction linings, mechanical equipment, gear transmission mechanisms, etc., to achieve the effects of reducing noise, soft braking process, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

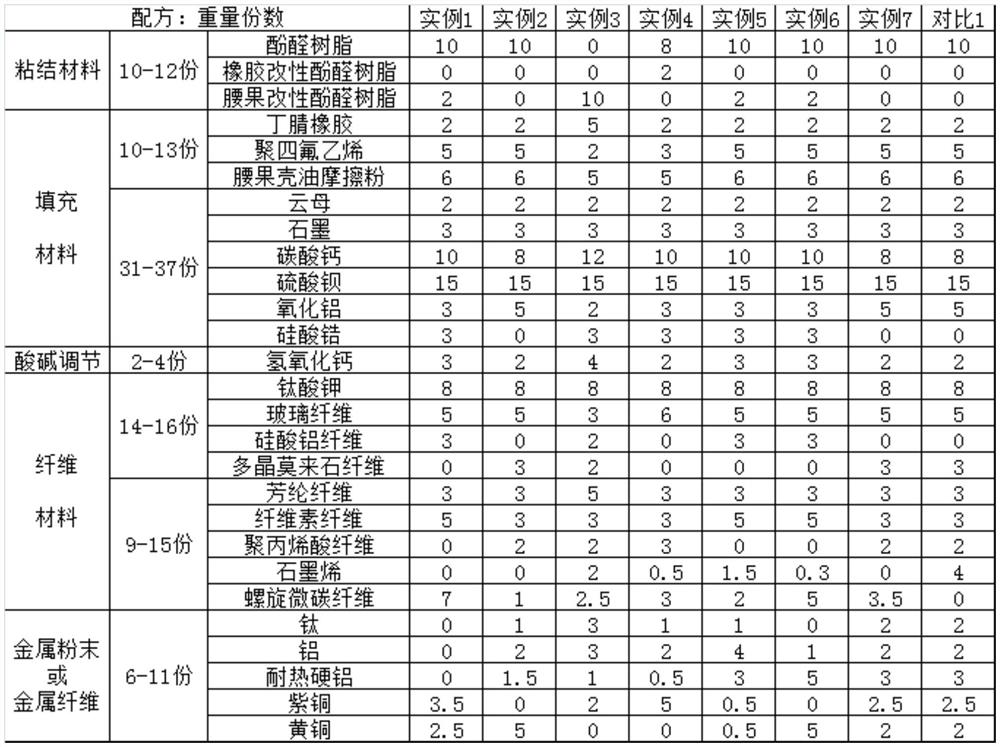

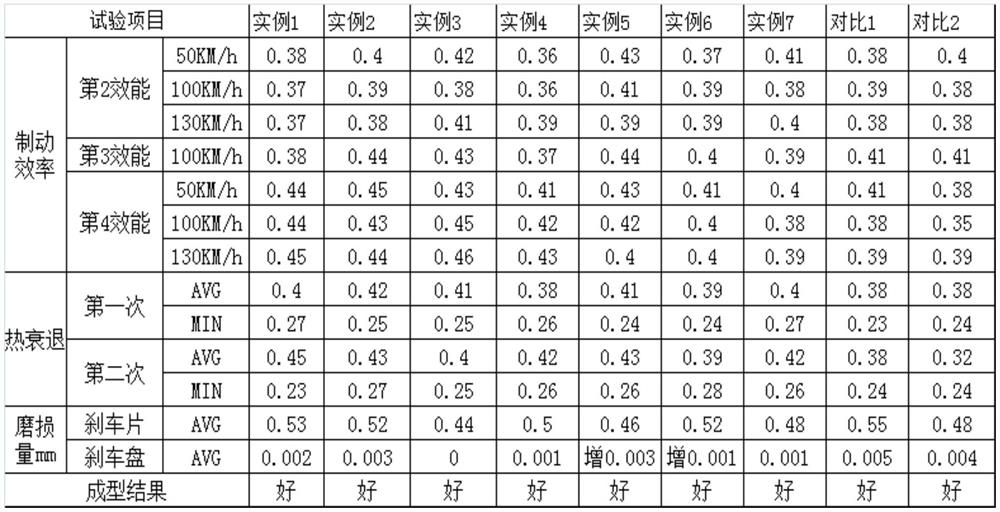

[0015] The invention provides an asbestos-free organic friction product for transmission and braking with less copper, which includes a base material, an adhesive layer and a friction layer made of an asbestos-free organic friction material for transmission and braking with less copper. The asbestos-free organic friction material used is composed of the following components by weight: 10-15 parts of bonding material, 45-50 parts of filling material, 25-35 parts of fiber material, 2-4 parts of acid-base adjustment material, metal 5-12 parts of fiber or metal powder, wherein the fiber material contains spiral micro-carbon fiber, the metal fiber or metal powder is one or more combinations of titanium, aluminum, heat-resistant duralumin, copper and brass, and the copper content less than 5%.

[0016] Preferably, the friction material is composed of the following components in parts by weight: 10-12 parts of bonding material, 46-49 parts of filling material, 25-31 parts of fiber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com