Double-clip type electrically operated butterfly valve

An electric butterfly valve, wafer type technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of leakage, affecting the service life of the butterfly valve, easy to be corroded, etc., and achieves good sealing effect, compact structure, and valve body structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

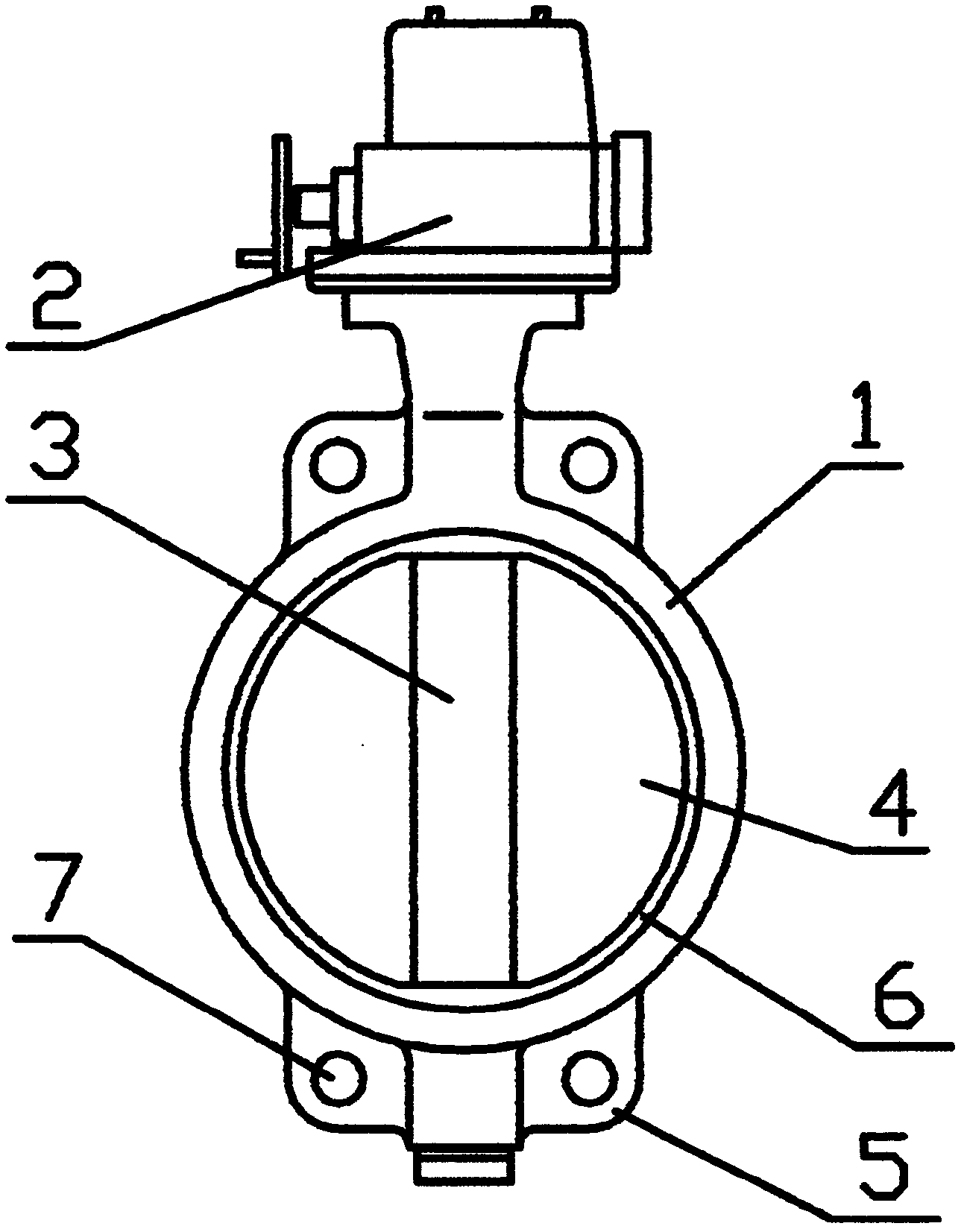

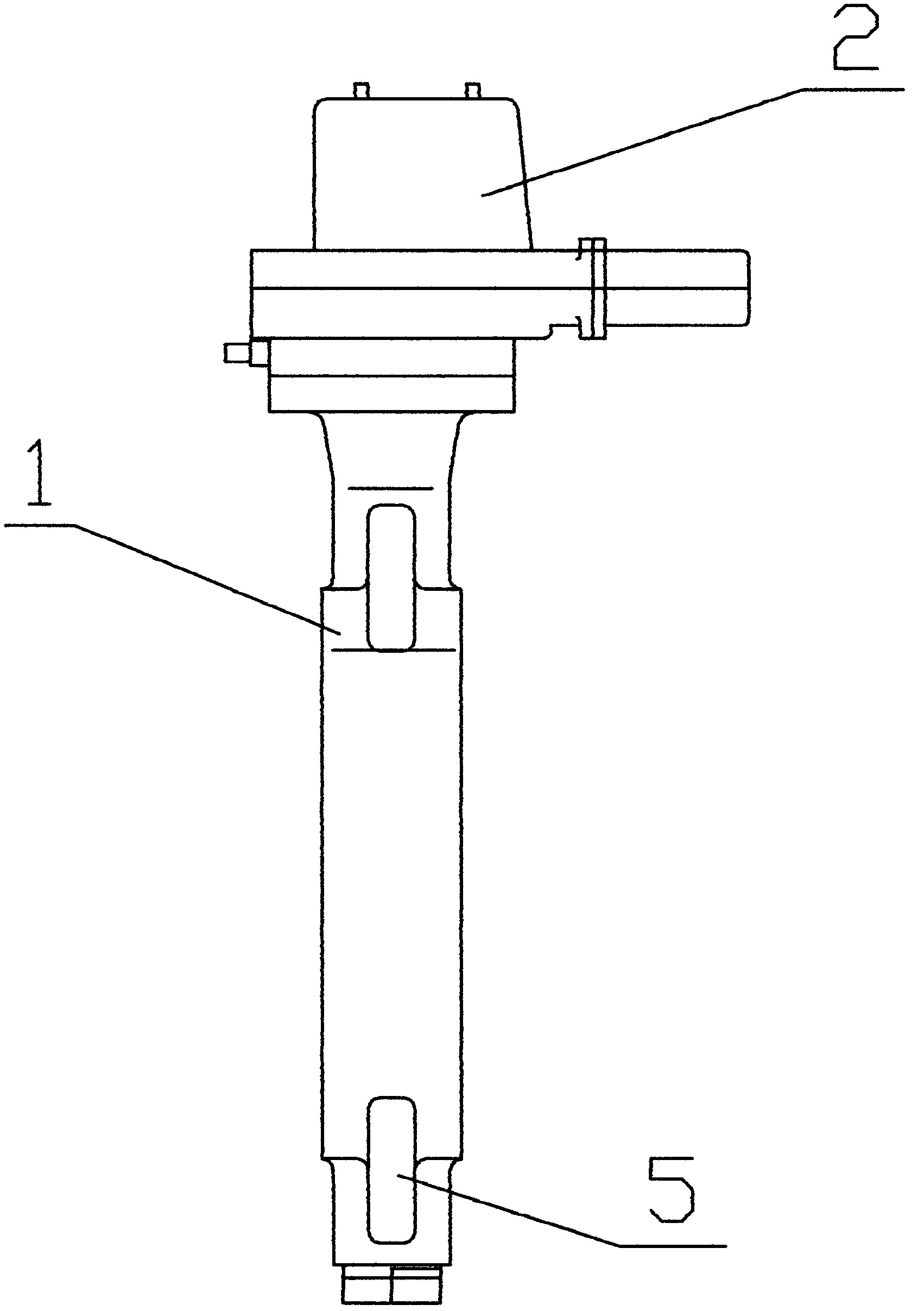

[0014] Such as figure 1 and figure 2 As shown, the wafer type electric butterfly valve includes a valve body 1 and an electric device 2. The valve body 1 is provided with a valve stem 3 and a valve plate 4. The upper end of the valve stem 3 protrudes from the valve body 1 and is connected to the electric device 2. The electric device 2 includes an electric drive head and a connection end, and the upper end of the valve rod 3 is connected and fixed with the connection end of the electric device 2 by screws; rubber is provided between the valve plate 4 and the sealing surface of the valve body 1 Circle 6.

[0015] In this embodiment, the upper and lower ends of the valve body 1 are respectively provided with outwardly protruding connecting ribs 5 , and two bolt holes 7 are respectively opened on the upper and lower connecting ribs 5 . In this embodiment, the rubber ring 6 is a nitrile rubber ring or a fluorine rubber ring, the valve stem 3 is made of stainless steel, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap