Multifunctional online cleaning device for condenser

A cleaning device and multi-functional technology, which is applied in the field of multi-functional online cleaning devices, can solve problems such as different layouts of condensation pipes, affecting power generation, and low reliability, so as to reduce equipment corrosion and environmental pollution, and reduce the number and time of outages , the effect of strong work adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

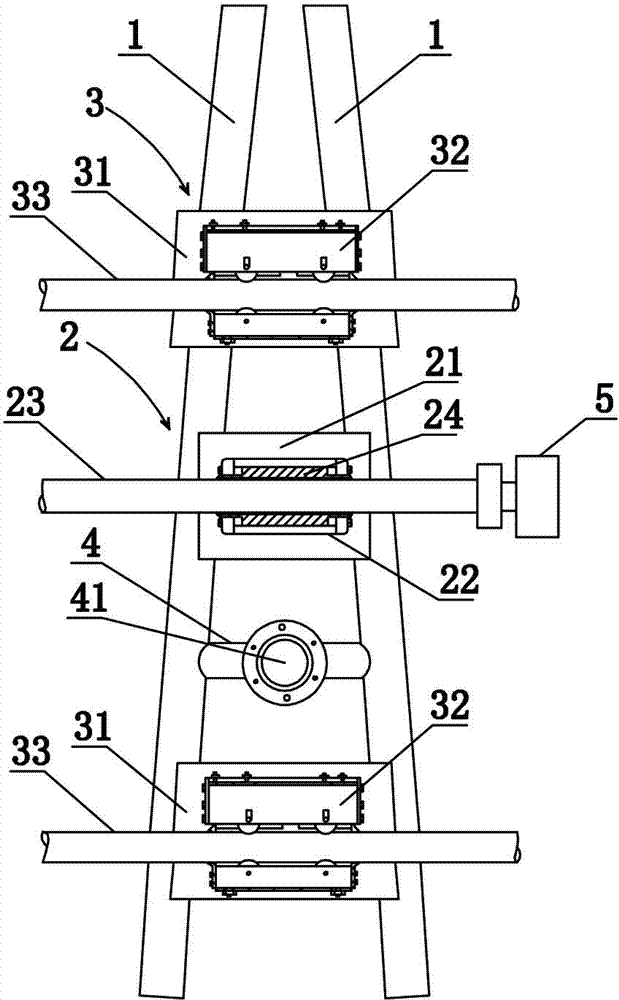

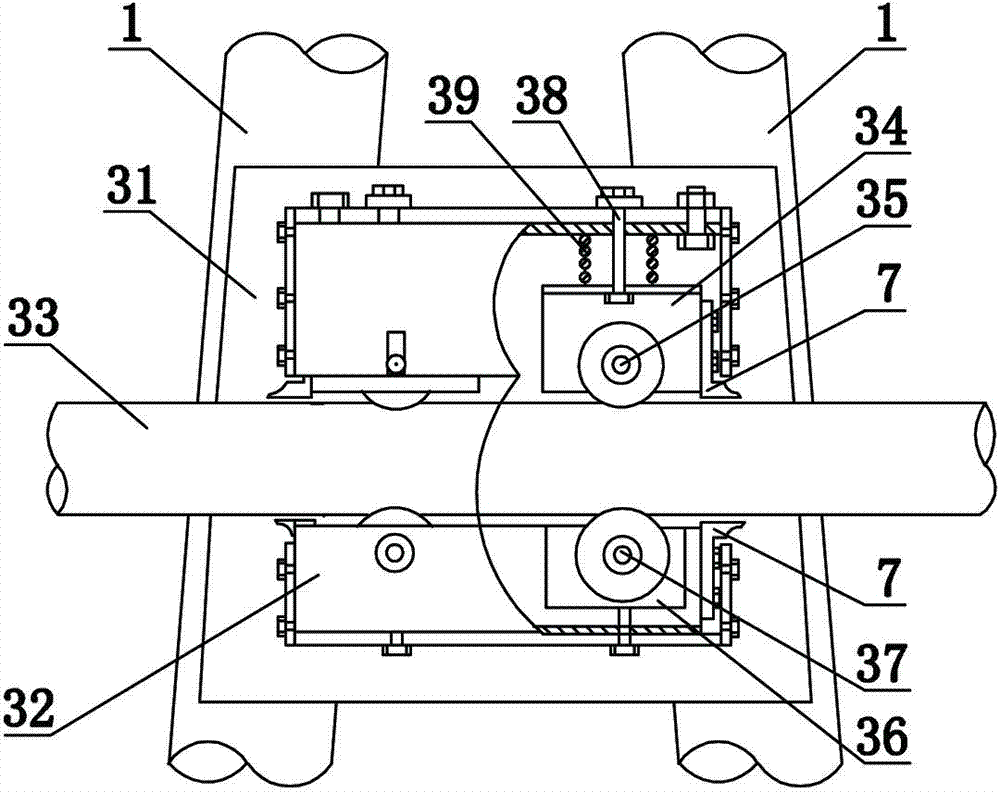

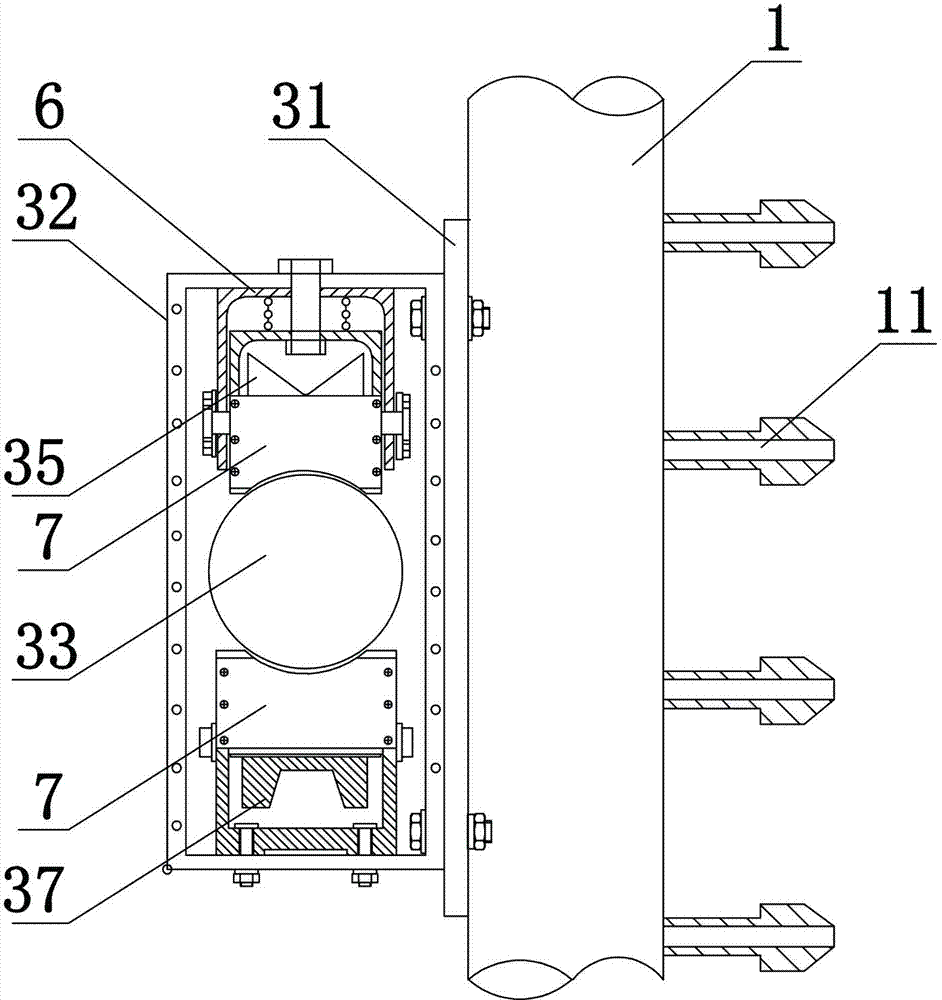

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a multifunctional on-line cleaning device for a condenser, it includes a frame, two nozzle master pipes 1 with two ends sealed respectively, a transmission mechanism 2 and two sets of guide mechanisms 3; wherein, the frame It can be a mounting frame installed inside the condenser water chamber, or the sidewalls on both sides of the condenser water chamber can be used as a frame; two sets of guide mechanisms 3 are symmetrically arranged on the upper and lower sides of the transmission mechanism 2, Make the whole device balance the upper and lower moments, and the structure is stable.

[0030] The two nozzle master pipes 1 are arranged in parallel or in a figure-eight shape, and the angle between the two nozzle master pipes 1 can be adjusted according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com