Two-dimensional airfoil type test platform

A test platform and airfoil technology, applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve problems such as complex design and difficulty in obtaining sufficiently accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

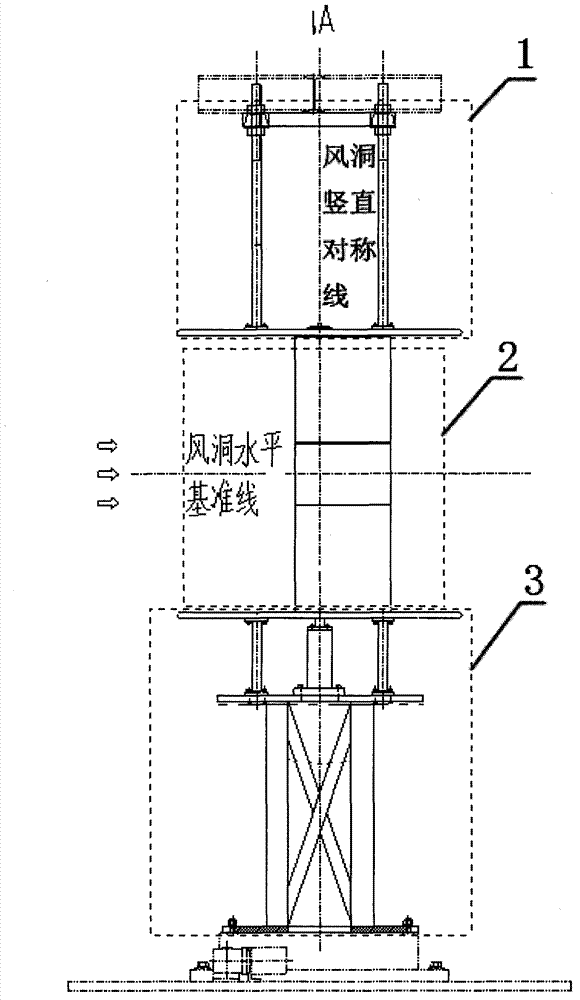

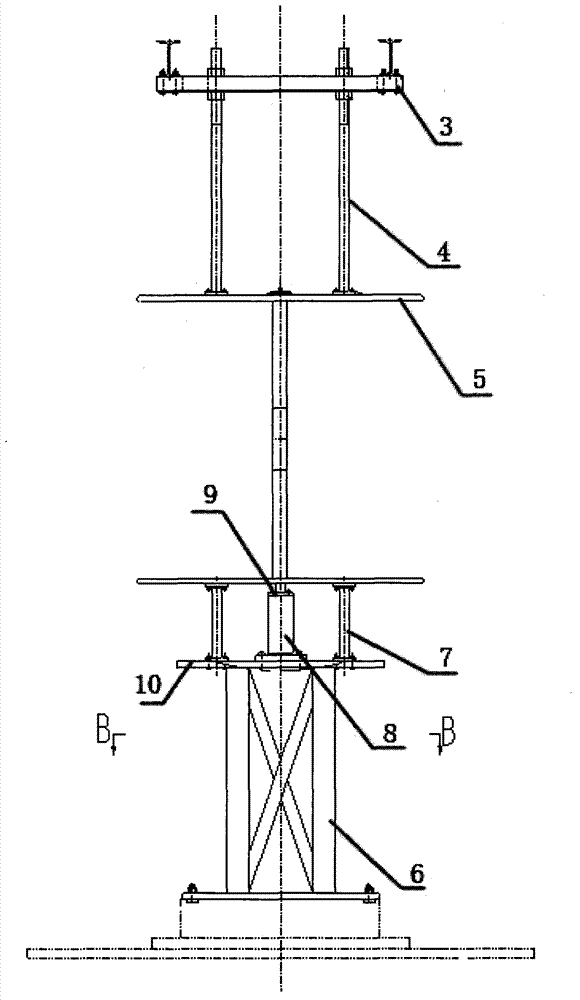

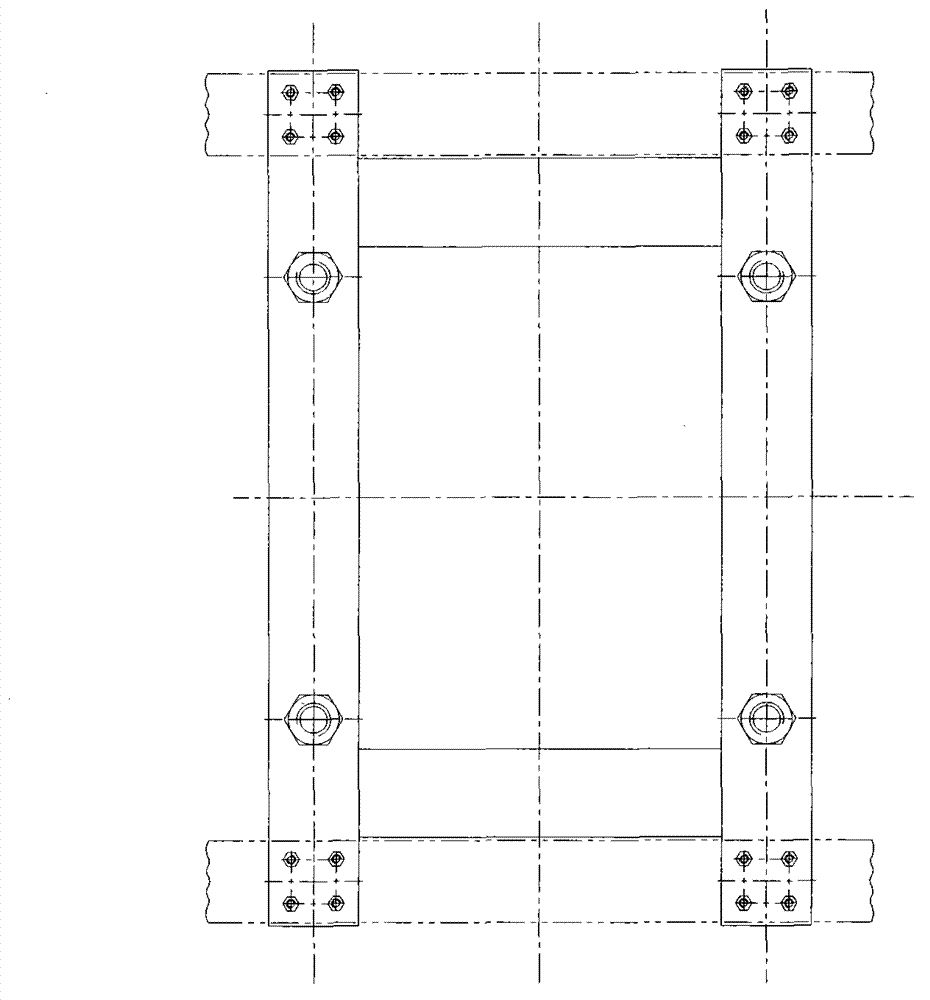

[0028] combine Figure 1-Figure 10 , a binary airfoil test platform, comprising an upper turntable unit 1, a lower turntable unit 3 and a test subject unit 2, the upper turntable unit 1 is connected to the test subject unit 2, the test subject unit 2 is connected to the lower turntable unit 3, and the upper turntable unit 1 It is connected with the I-beam on the upper floor of the wind tunnel, and the lower turntable unit 3 is connected with the turntable of the wind tunnel. The upper turntable unit includes an upper frame 3, a plurality of connecting rods 4 and an upper end plate 5, the upper frame 3 is fixed on the I-beam at the upper floor of the wind tunnel, and the upper frame 3 is fixedly connected with one end of a plurality of connecting rods 4 , the other ends of the plurality of connecting rods 4 are fixedly connected to the upper end plate 5 . The lower turntable unit includes a base 6, four support rods 7, a first support base 8, a second support base 9 and a lowe...

Embodiment 2

[0030] Using the turntable system of the wind tunnel, the model adopts the vertical installation method, adopts the NACA0015 airfoil, and the chord length is 250mm. In order to reduce the influence of the three-dimensional flow, the length of the measurement section is only 200mm, and the non-measurement section (following part) is symmetrically arranged in the measurement section. On both sides, plexiglass end plates (PMMA) are installed at both ends to eliminate the spanwise flow of the airfoil. The distance between the end plates is 800mm. The end plates are made of transparent materials for the convenience of flow observation. The non-measuring section of a certain length can avoid bringing the flow distortion of the end plate and the corner pocket of the airfoil to the measuring section. There is a gap of 0.5mm between the measuring section and the non-measuring section to prevent the two sections from colliding during deformation. At the same time, effective soft connect...

Embodiment 3

[0032] The lower turntable unit is installed on the lower turntable system of the wind tunnel, and the upper turntable unit is fixed on the beam at the upper part of the test section. The upper and lower turntable units are connected by a three-section shaft, the airfoil is equipped with a central shaft, the lower part of the lower shaft is connected with the lower turntable, and the upper part of the upper shaft is connected with the upper turntable unit through self-aligning bearings, so that it can ensure When the rotation of the wind tunnel turntable drives the lower turntable unit of the mechanism to rotate, the upper turntable unit does not move, and the airfoil rotates with the rotation of the lower turntable. The advantage of this is that there are no redundant structures such as beams and columns around the airfoil flow field to affect the flow field, which will greatly facilitate the measurement of the airfoil wake. The airfoil is molded with high compressive non-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com