Reaction device for pyrolyzing chemical raw materials by adopting steam

A technology for chemical raw materials and reaction devices, applied in pressure vessels, heat treatment, chemical instruments and methods used in chemical processes, etc., can solve problems such as adverse effects of experimental product analysis, inability to form biomass carbon preparation, and reducing the accuracy of experimental results. , to achieve the effect of shortening the cooling time, strengthening the heat exchange, and enhancing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

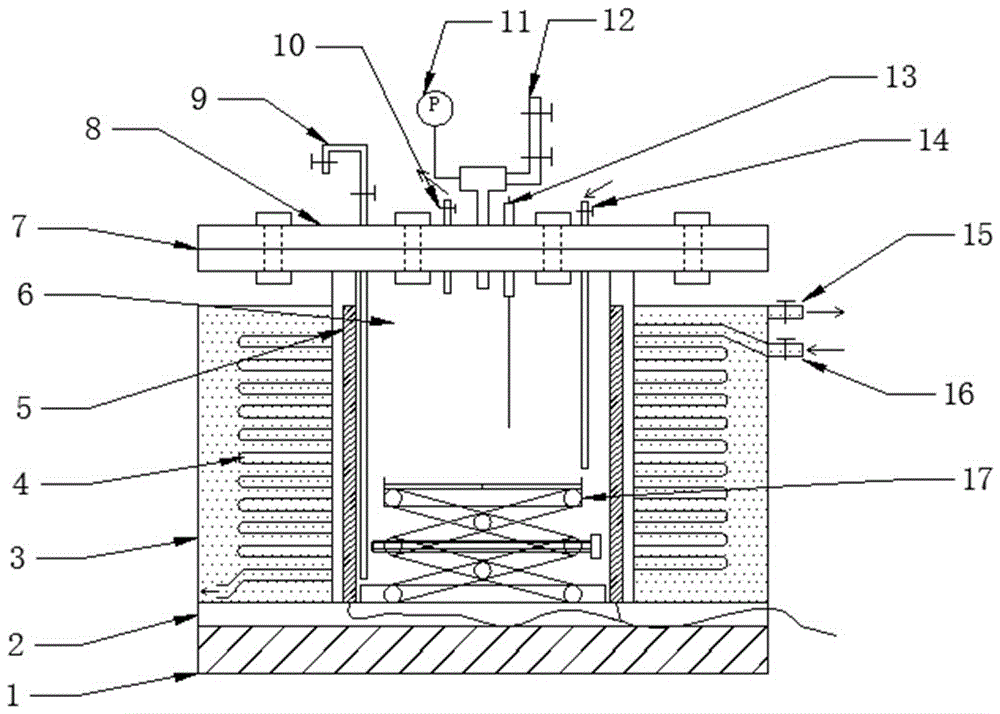

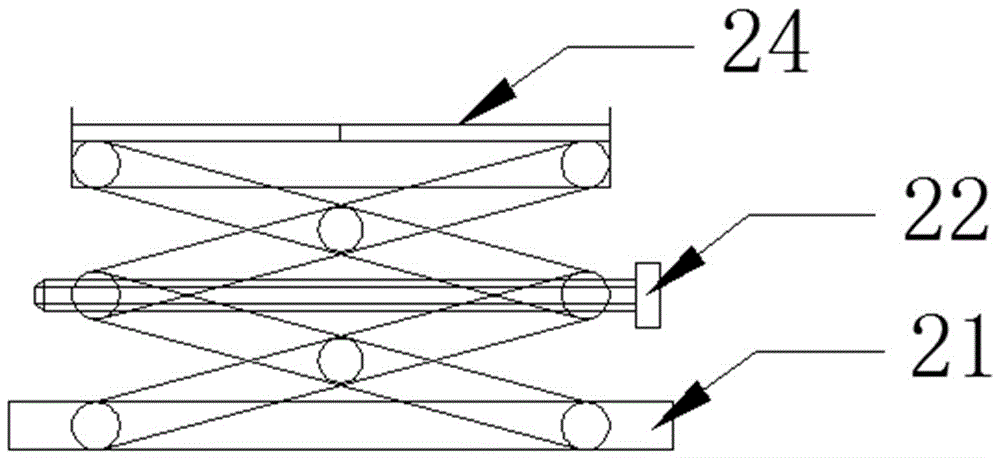

[0032] see figure 1 , a reaction device using steam pyrolysis of chemical raw materials includes a cylindrical cavity 6, the outside of the cavity 6 is sequentially fitted with a heating mechanism 2 and a cooling mechanism; the top of the cavity 6 is provided with an everted flange 7 , The flange side 7 and the top cover 8 are sealed and connected by a gasket. The top cover 8 is equipped with an exhaust pipe 10, an air intake pipe 14, a liquid sampler 9 and a safety unloading valve 12 connected to the inside of the cavity 6, an exhaust valve is installed on the exhaust pipe 10, and an inlet valve is installed on the air intake pipe 14. Air valve; sampler 9 includes a sampling tube, the lower part of the sampling tube is located in the cavity 6, and a sampling valve is installed on the top of the sampling tube. A pressure gauge 11 and a temperature sensor 13 are also installed on the top cover 8 . The inside of the cavity 6 is equipped with a loading bracket 17; see figure ...

Embodiment 2

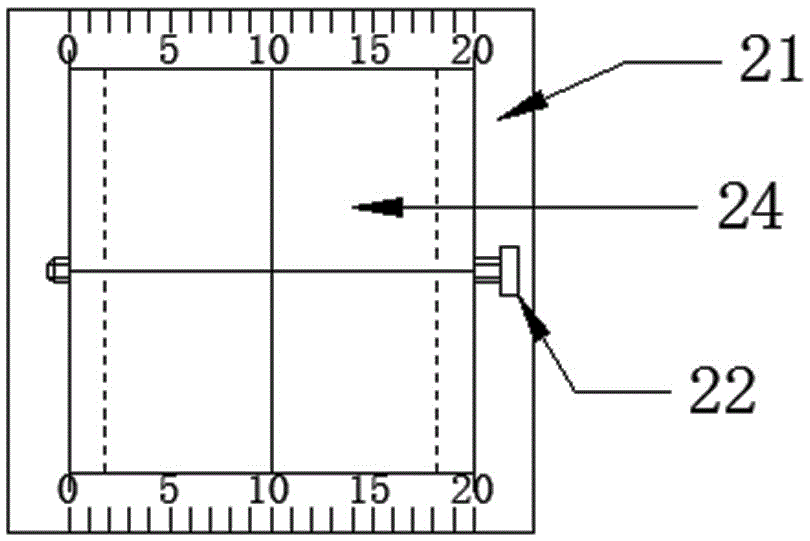

[0039] see image 3 , The loading tray 24 is divided into four small plates, which can realize simultaneous pyrolysis reactions on four different substances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com