Debugging method of static balance valve

A debugging method and static balancing technology, which is applied to balance valves, safety valves, valve devices, etc., can solve the problems that static balancing valves cannot achieve dynamic balancing valves, cannot automatically make adjustments, waste heat and material resources, etc., and achieve debugging High efficiency, saving manpower and material resources, less interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

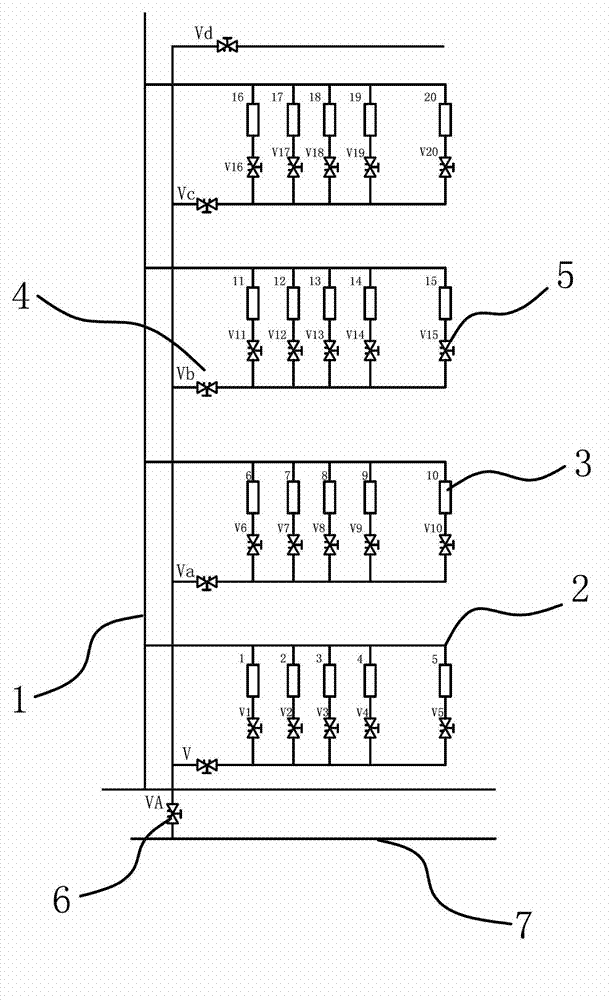

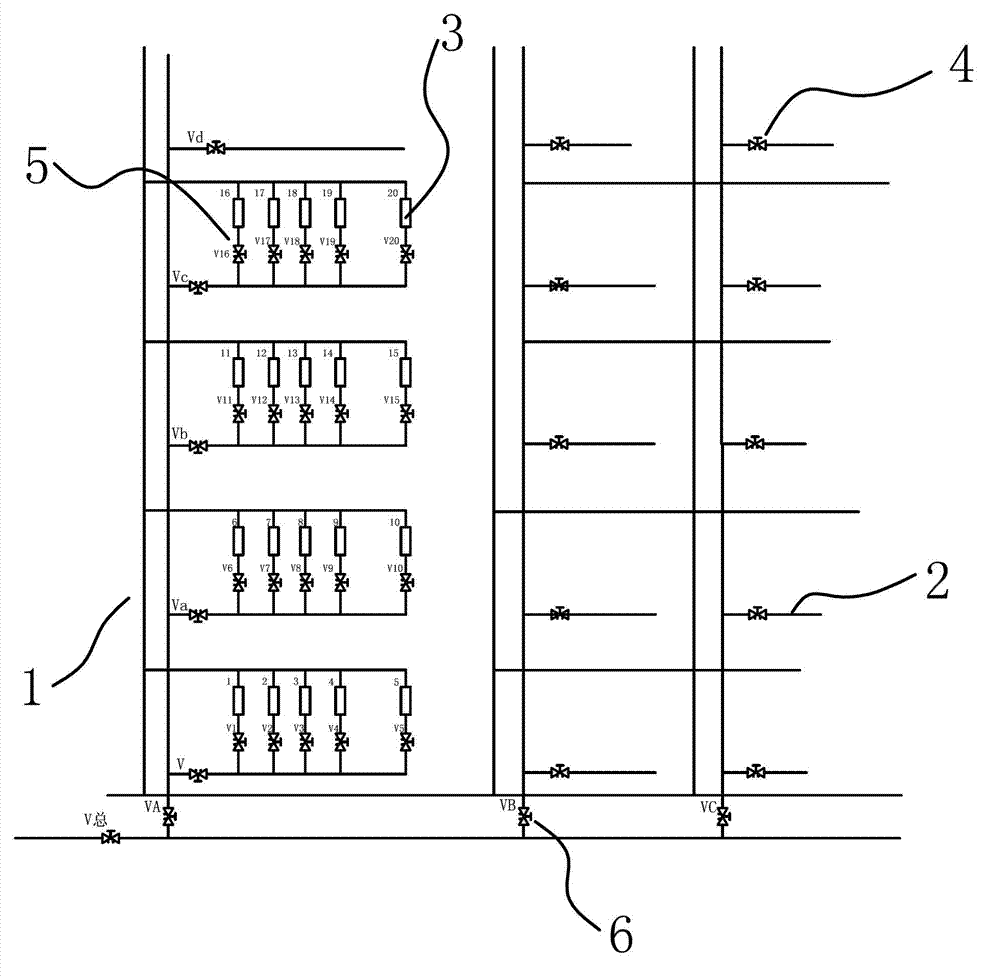

[0035] The debugging method of this static balance valve is used to debug all the branches in the hydraulic system are connected in parallel, starting from a water inlet pipeline and returning to the balance valve of the same return water pipeline, so that the flow ratio of all the balance valves in the system Both are equal to 1.

[0036] Step A. Select the standpipe with the largest flow ratio:

[0037] Fully open all balance valves, automatic valves, and normally on / off valves, adjust the main balance valve, control the pump flow rate to be between 100% and 110% of the design flow rate, determine the design flow rate of all standpipe 1, and measure the flow rate of all standpipe 1 Actual flow, and calculate the flow ratio of each standpipe 1: flow ratio = actual flow / design flow, select the standpipe 1 with the largest flow ratio;

[0038] Step B. Select the branch pipe with the maximum flow ratio:

[0039] Determine the design flow rate of all branch pipes 2 on the selec...

Embodiment 2

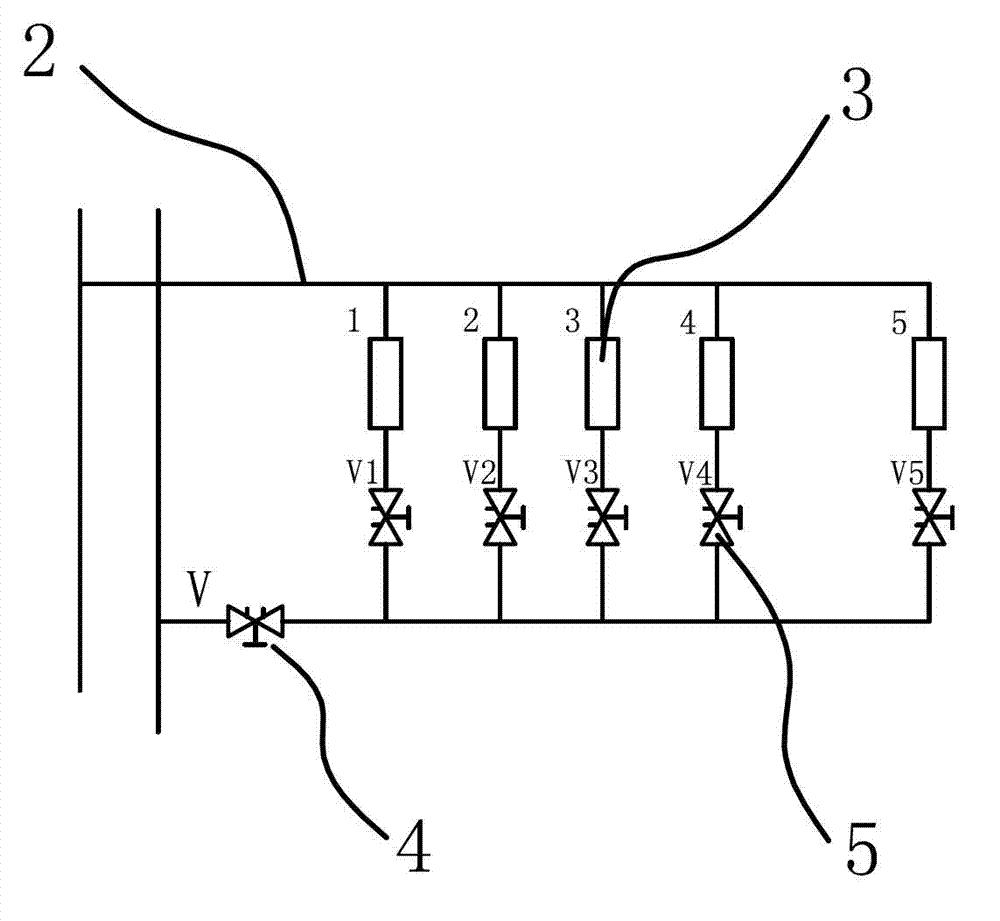

[0056] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the branch pipe in this embodiment includes a branch balance valve V, four end devices 1, 2, 3, 4 and four end balance valves V 1 , V 2 , V 3 , V 4 , adopt the same debugging method as in embodiment 1 to adjust the hydraulic system, and finally make the flow ratios of all balance valves equal to 1.

Embodiment 3

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the branch pipe in this embodiment includes a branch balance valve V, eight terminal devices 1, 2, 3, 4, 5, 6, 7, 8 and eight end balance valves V 1 , V 2 , V 3 , V 4 , V 5 , V 6 , V 7 , V 8 , adopt the same debugging method as in embodiment 1 to adjust the hydraulic system, and finally make the flow ratios of all balance valves equal to 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com