Compound winding made of Bi-based and Y-based high-temperature superconducting tapes

A high-temperature superconducting strip and high-voltage winding technology, which is applied to superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problem of uneven current distribution of multiple series and parallel windings, and achieve less critical current drop and cost-effective Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

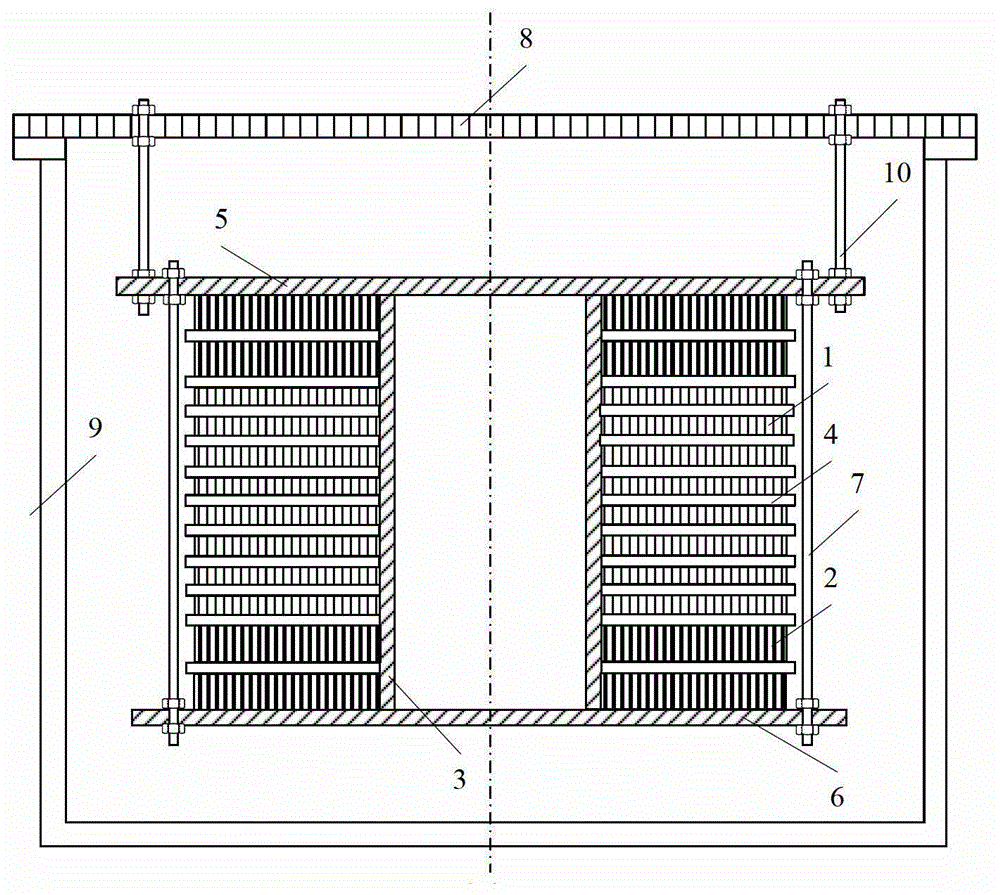

[0021] Example 1 is a combined winding structure using Bi-based and Y-based high-temperature superconducting tapes, using multiple double-cake coils connected in parallel, which can be applied to superconducting reactors, superconducting energy storage magnets and superconducting strong-field magnets, etc. multiple fields. like figure 1 As shown, the combined winding structure consists of a Bi-based superconducting double-cake coil 1, a Y-based superconducting double-cake coil 2, a coil bobbin 3, a coil axial spacing layer 4, a coil upper support plate 5, and a coil lower support plate 6 , coil fastening screw 7, low temperature Dewar cylinder 8, low temperature Dewar upper cover 9 and pull rod 10. The Bi-based superconducting double-cake coil 1 and the Y-based superconducting double-cake coil 2 are wound outside the coil frame 3 , and the double-cake superconducting coils are separated by a coil axial spacer layer 4 . The coil upper support plate 5 and the coil lower suppor...

Embodiment 2

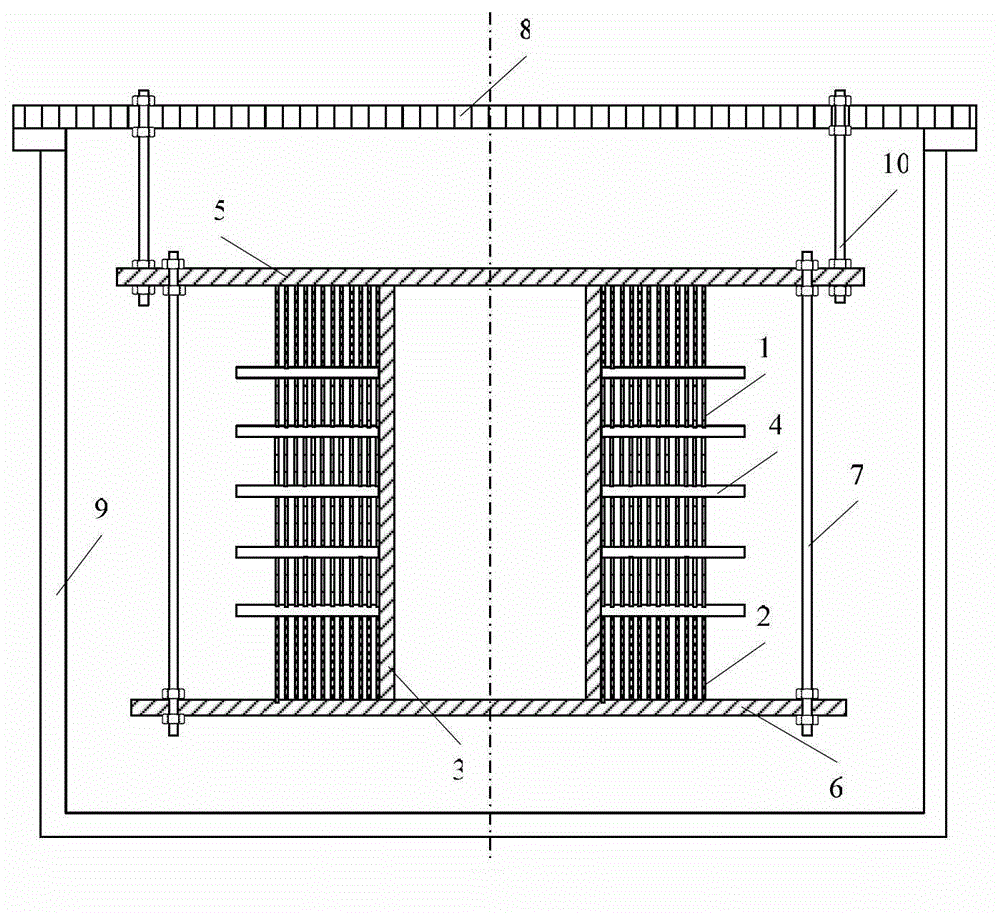

[0023] Embodiment 2 is a combined winding structure using multiple cylindrical structure coils connected in parallel, which is wound with Bi-based and Y-based high-temperature superconducting tapes, and can be applied to superconducting reactors, superconducting energy storage magnets and superconducting strong-field magnets and many other fields. like figure 2 As shown, the combined winding structure consists of Bi-based superconducting cylindrical coil 1, Y-based superconducting cylindrical coil 2, coil bobbin 3, coil axial spacing layer 4, coil upper support plate 5, and coil lower support plate 6 , coil fastening screw 7, low temperature Dewar cylinder 8, low temperature Dewar upper cover 9 and pull rod 10. The Bi-based superconducting cylindrical coil 1 and the Y-based superconducting cylindrical coil 2 are wound outside the coil frame 3 , and the superconducting cylindrical coils are separated by a coil axial spacer layer 4 . The coil upper support plate 5 and the coi...

Embodiment 3

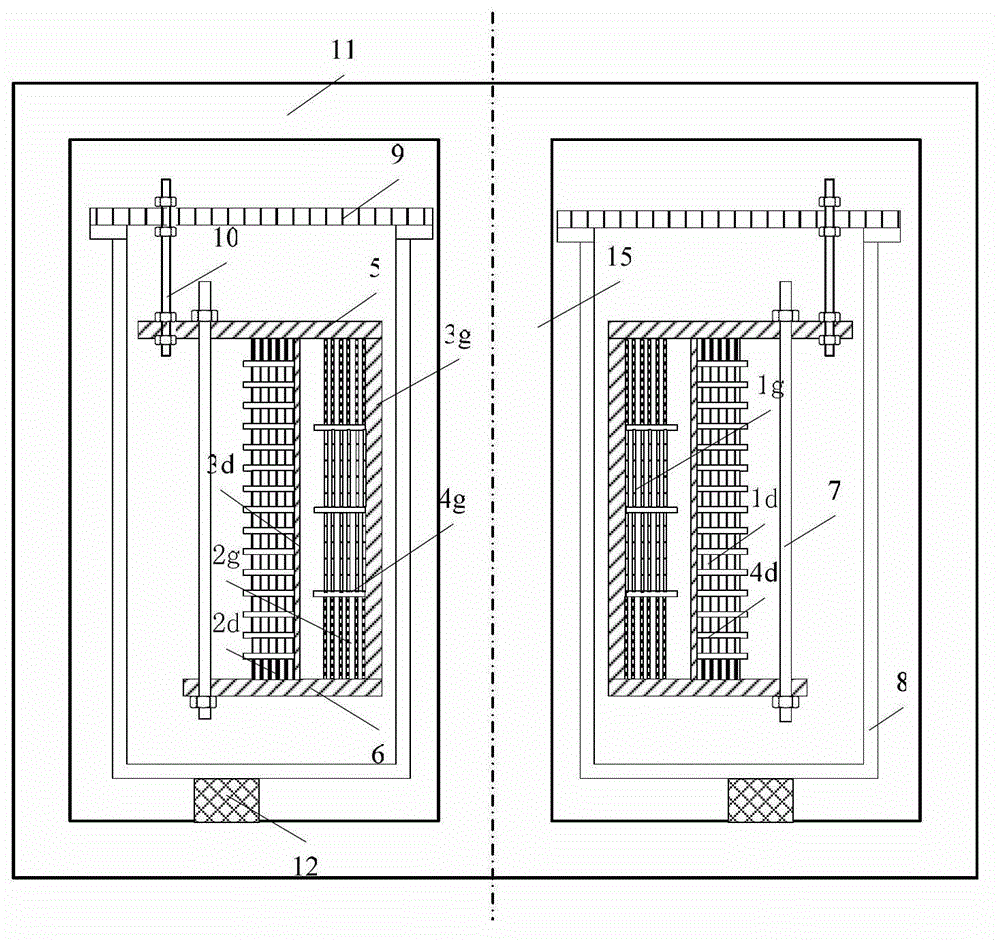

[0025] Embodiment 3 is a combined winding structure made of Bi-based and Y-based high-temperature superconducting tapes applied to superconducting transformers. like image 3 As shown, the superconducting transformer is composed of a Bi-based superconducting cylindrical coil 1g and a Y-based superconducting cylindrical coil 2g applied to the high-voltage winding, a Bi-based superconducting double-cake coil 1d and a Y-based superconducting coil applied to the low-voltage winding. Superconducting double pie coil 2d, high-voltage winding frame 3g and low-voltage winding frame 3d, high-voltage winding coil axial spacer layer 4g and low-voltage winding coil axial spacer layer 4d, winding upper support plate 5, winding lower support plate 6, winding tight Solid screw rod 7, low temperature Dewar barrel 8, low temperature Dewar upper cover plate 9, tie rod 10, transformer iron core 11 and low temperature Dewar pad 12 constitute. The high-voltage winding composed of the Bi-based supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com