lead battery

A lead-acid battery, composite technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of filling amount deviation, separation, filling density unevenness, etc., and achieve the effect of suppressing deviation

Active Publication Date: 2017-06-30

GS YUASA INT LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

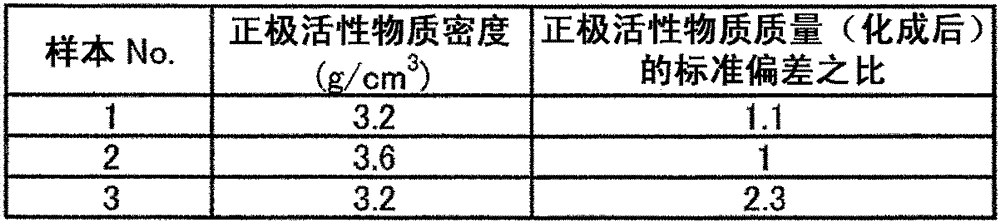

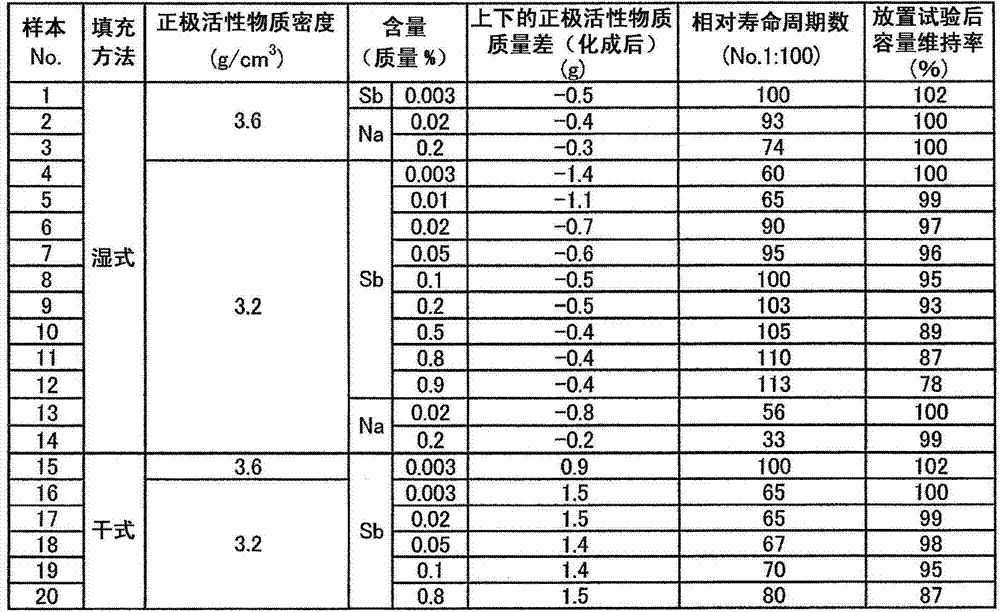

[0004] In the case of using such a wet filling method to make a composite positive plate, when the fluidity of the positive active material paste (or slurry) decreases, it is easy to cause deviations in the filling amount and uneven filling density.

And, when the density of the positive electrode active material raw material paste (or slurry) is low, since the solid-liquid separation of the paste (or slurry) is easily caused, it is easy to cause the deviation of the filling amount and the unevenness of the filling density.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032] Hereinafter, although an Example is given and this invention is demonstrated in more detail, this invention is not limited to the said Example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a composite lead acid battery capable of suppressing variations in the filling amount and packing density of active materials in a positive electrode plate produced by a wet filling method. In the lead acid battery provided with the composite positive electrode plate produced by the wet filling method, the said composite positive electrode plate contains 0.02 mass % or more of antimony in the positive electrode active material after chemical conversion.

Description

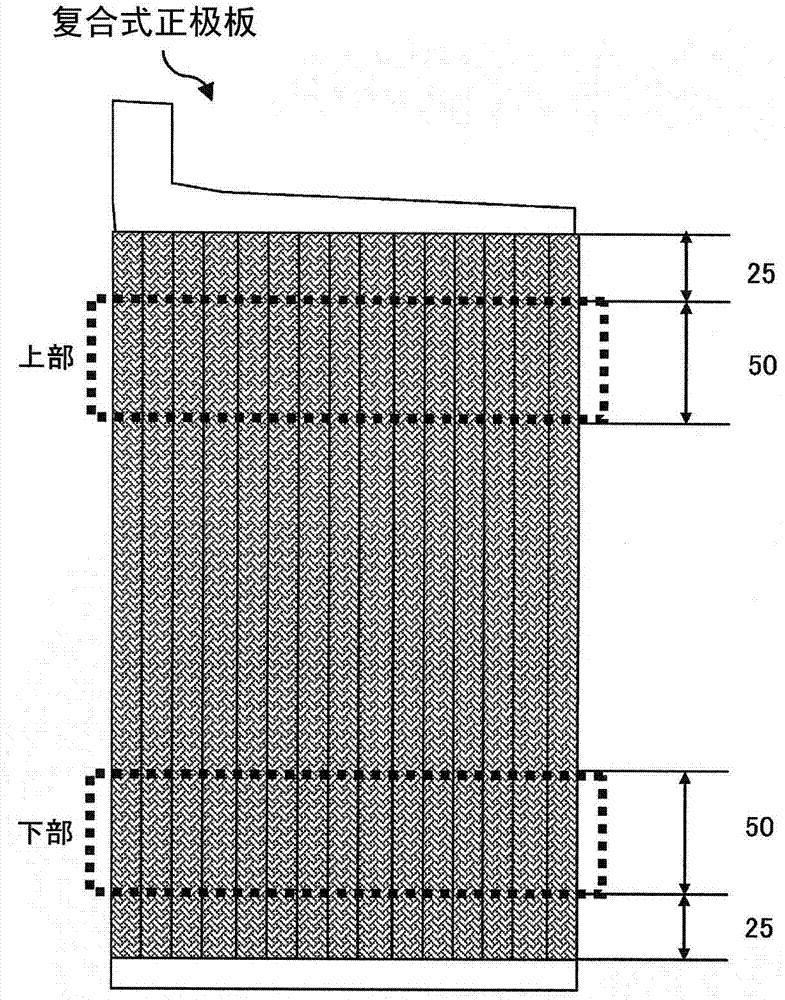

technical field [0001] This invention relates to the lead acid storage battery provided with the composite positive electrode plate produced by the wet filling method. Background technique [0002] A lead alloy core is passed through the center of a porous cylindrical tube made of glass fibers, and the surrounding area is filled with active material raw materials, so that it is manufactured through chemical conversion and other processes. Used in batteries for recycling purposes such as forklift batteries Composite positive plate used. As a method of filling the active material raw material into the tube, although the dry filling method and the wet filling method are mentioned (Patent Document 1), since the dry filling method generates lead oxide dust during the filling operation, the operating environment From the point of view, the wet filling method is better, wherein the dry filling method fills the lead oxide while applying vibration, and the wet filling method uses di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M10/06H01M4/38H01M4/14H01M10/12

CPCY02E60/10Y02P70/50

Inventor 渡边仁藤田晃平

Owner GS YUASA INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com