Novel busway with large current and low voltage

A busbar, high current technology, applied in the field of busbars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing

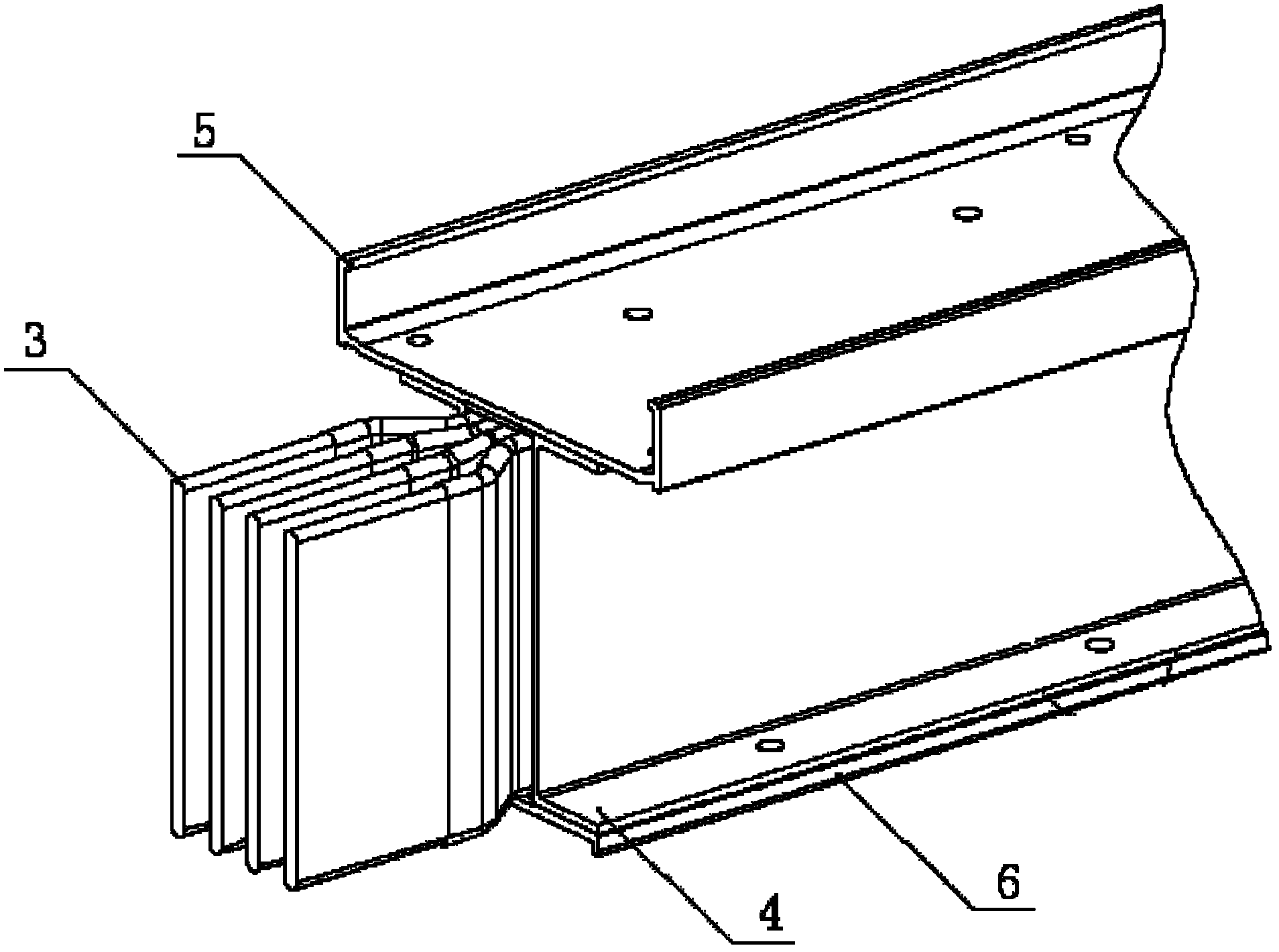

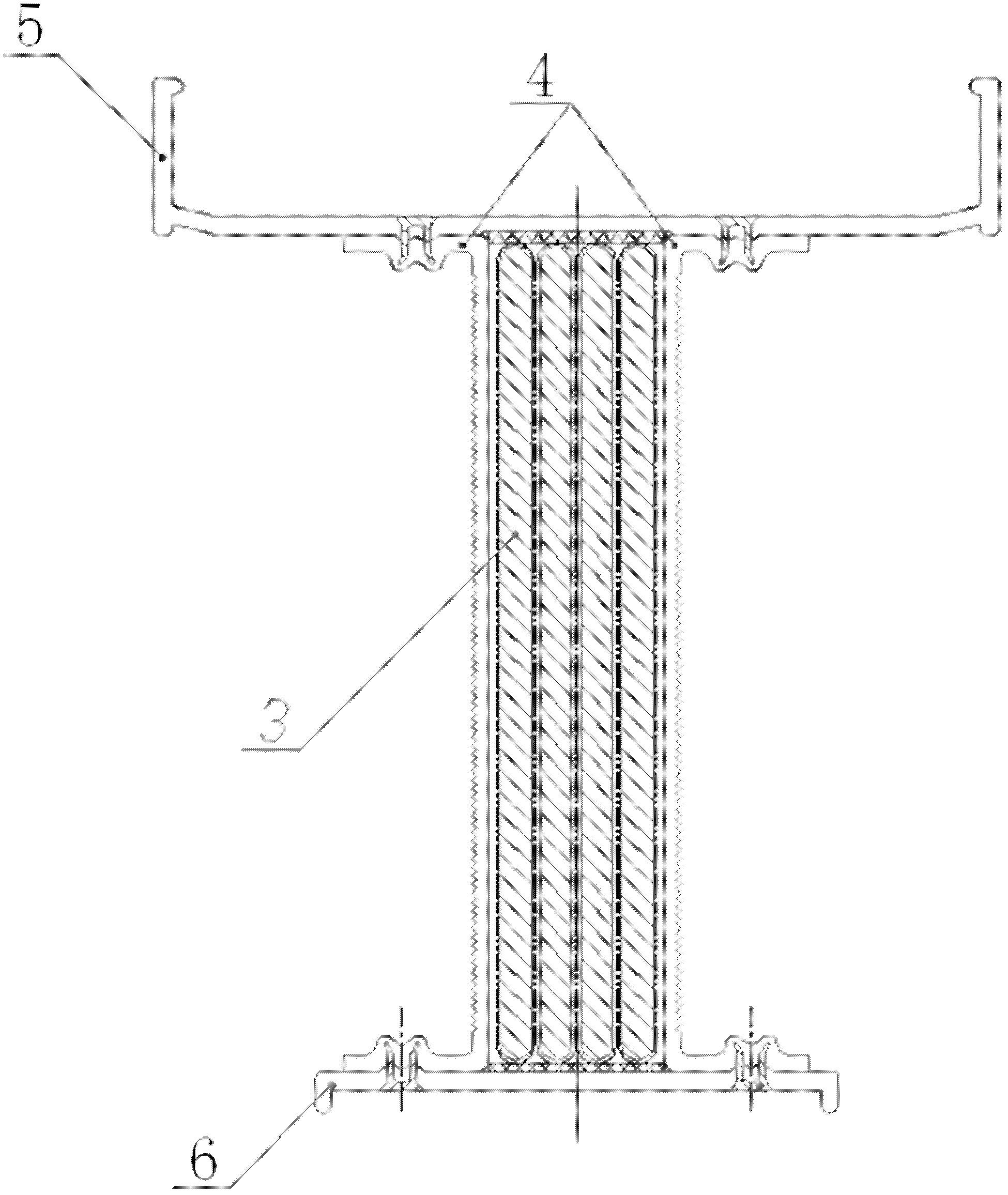

[0022] A new type of high-current low-voltage busway, which includes two upper and lower busway unit mechanisms, which are connected together by a connecting device to form an overall structure of the busway. The structure of the connection device is: the upper and lower reinforcing ribs 1 of the bus duct are arranged between the upper and lower bus duct unit mechanisms, and the upper and lower bus duct unit mechanisms and the upper and lower reinforcing ribs 1 of the bus duct are connected as a whole by bolts.

[0023] The left and right reinforcement plates 2 are arranged on the left and right sides of the overall structure of the bus duct; the left and right sides of the overall structure of the bus duct are fixedly connected with the left and right reinforcement plates 2 by bolts; The plates 2 are fixedly connected together; thereby forming a single unit.

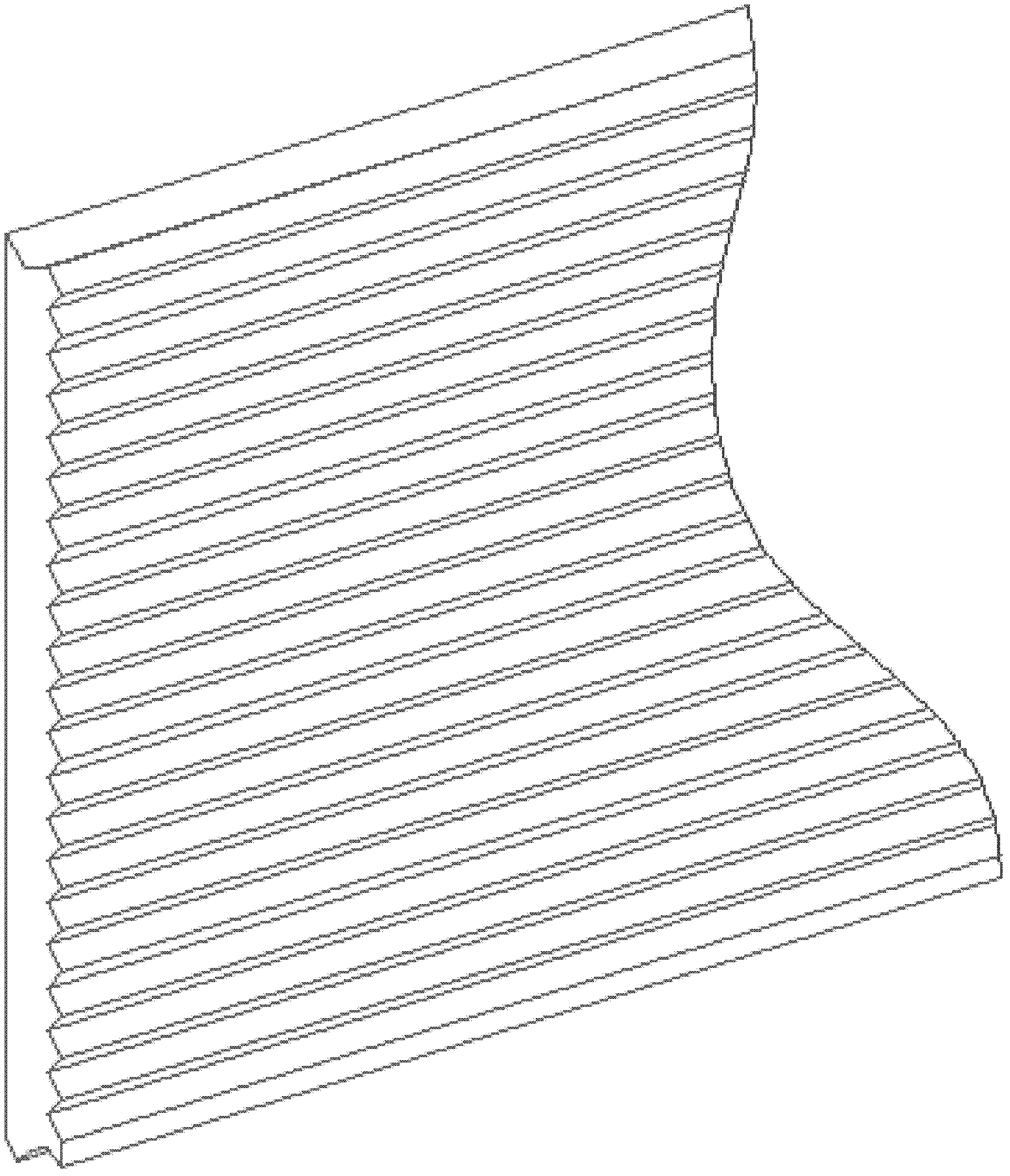

[0024] The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com