Press fit method for to-be-pressed multi-layer plate with chip window

A multi-layer board and window technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as failure to meet application requirements, and achieve the effects of avoiding product scrapping, improving force uniformity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

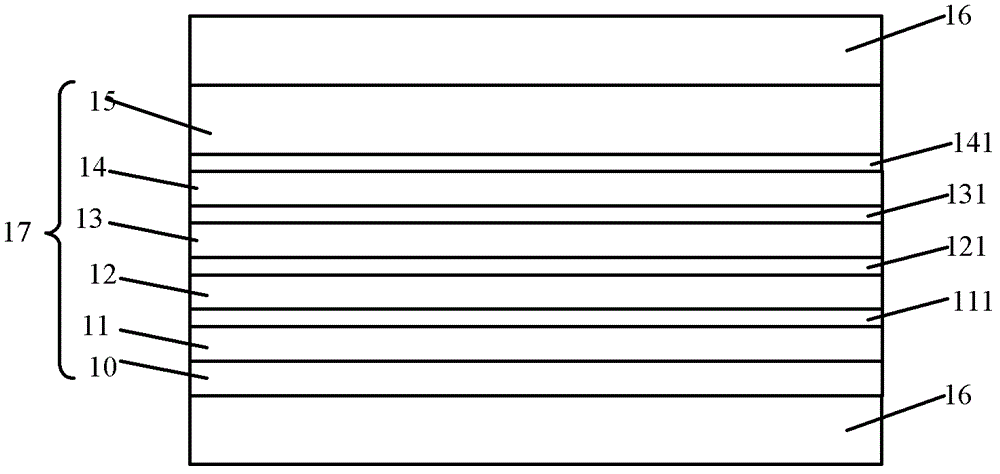

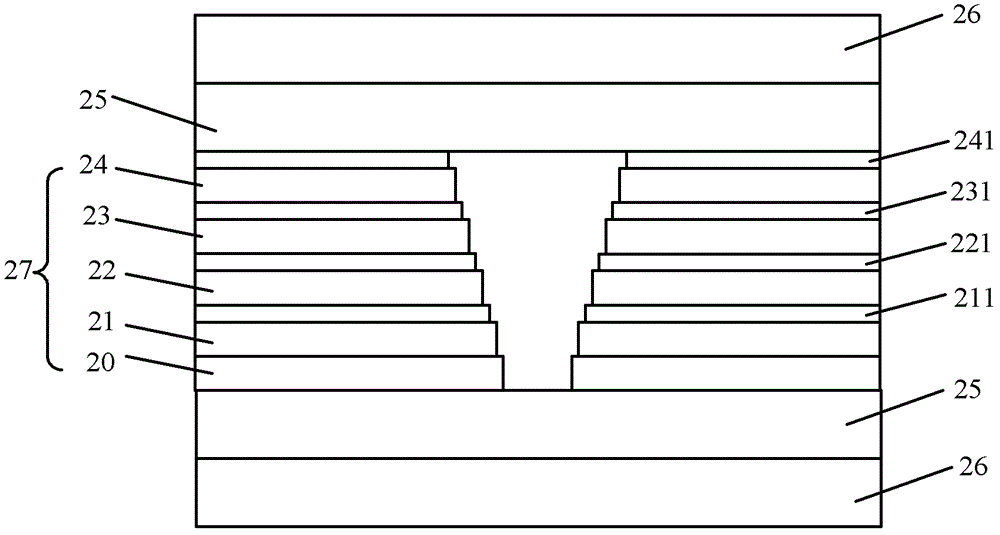

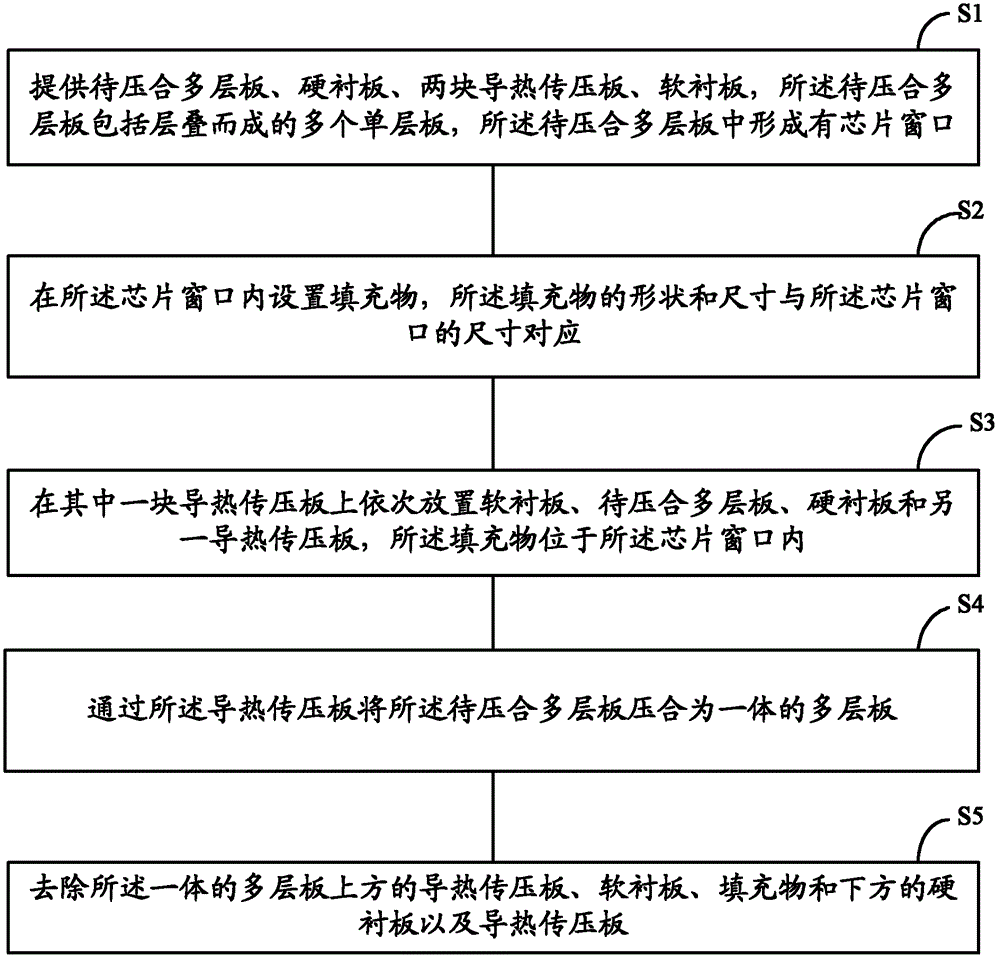

[0034] Please refer to the lamination principle of the existing multi-layer board with chip window figure 2 shown. The multi-layer board 27 to be laminated in the figure includes a plurality of single-layer boards stacked, which are respectively:

[0035] The first prepreg 21; the first wiring layer 211 located on the first prepreg 21 (the first prepreg 21 and the first wiring layer 211 form a first single-layer board); located on the first wiring layer 211 The second prepreg 22 on the top; the second wiring layer 221 on the second prepreg 22 (the second prepreg 22 and the second wiring layer 221 form a second single-layer board); The third prepreg 23 on the second wiring layer 221; the third wiring layer 231 on the third prepreg 23 (the third prepreg 23 and the third wiring layer 231 constitute a third single-layer board ); the fourth prepreg 24 on the third wiring layer 231; the fourth wiring layer 241 on the fourth prepreg 24 (the fourth prepreg 24 and the fourth wiring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com