Front illumination device comprising a film-based lightguide

A light guide and light source technology, applied in lighting devices, parts of lighting devices, light guides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0934] Certain embodiments are illustrated in the following examples. The following examples are given for illustrative purposes only, and do not limit the scope or spirit of the invention.

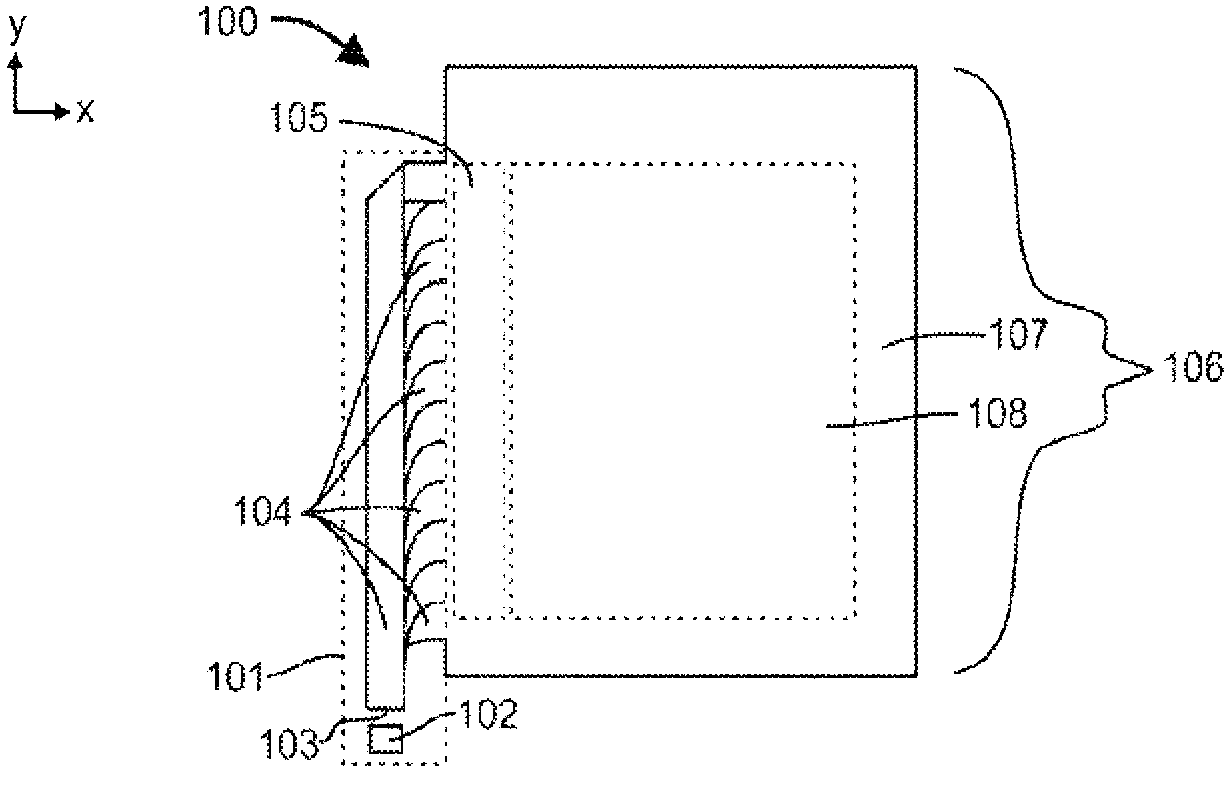

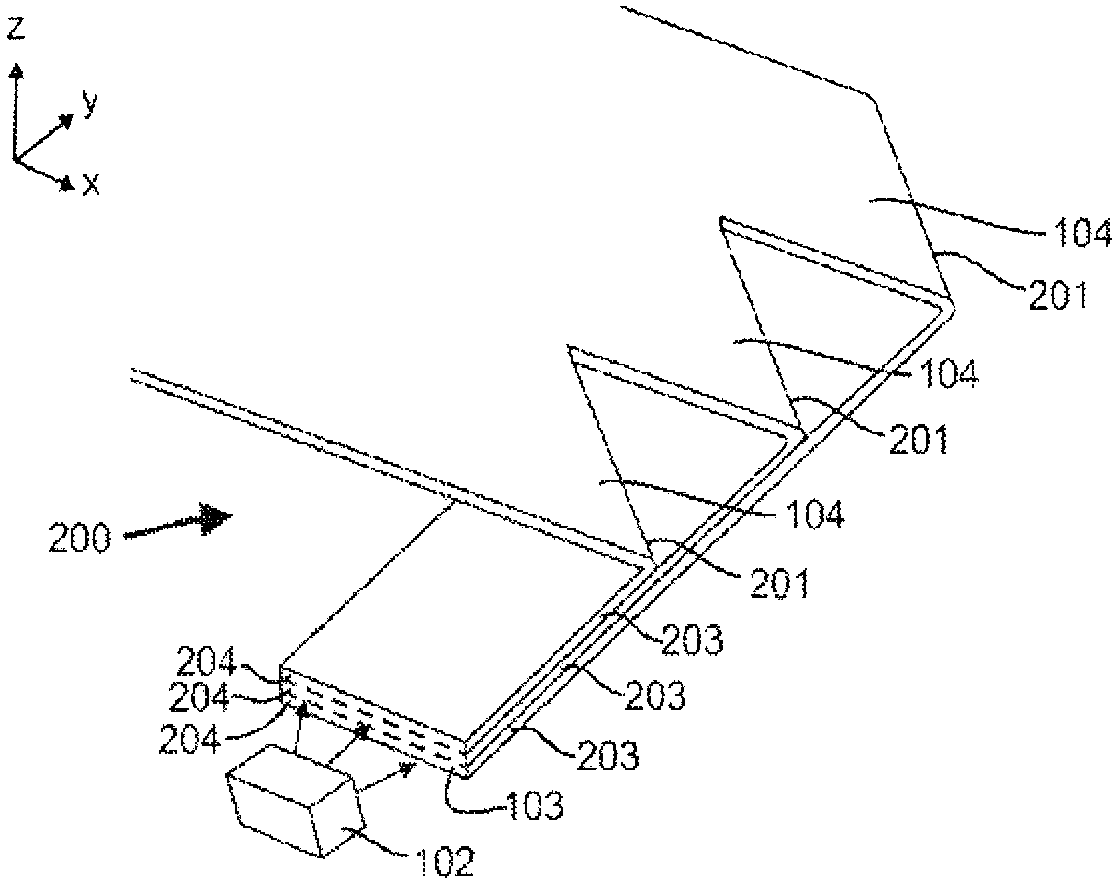

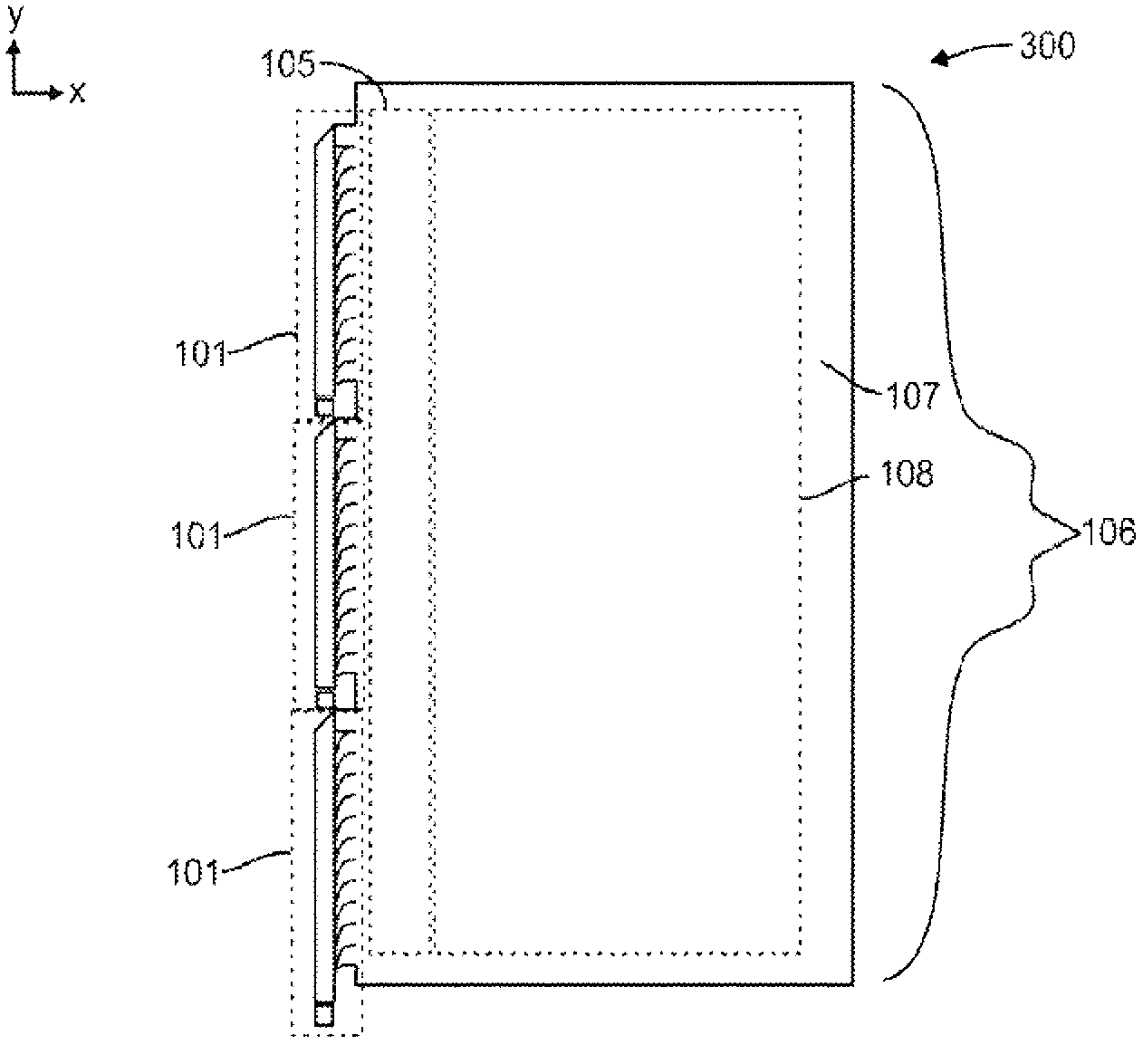

[0935] In one embodiment, the coupling lightguides are formed by cutting strips at one or more ends of the film forming the coupling lightguides (strips) and the lightguide region (remainder of the film). On the free end of the strip, the strip is bundled together into an arrangement, the strip being thicker than the thickness of its membrane. On the other end, they are still physically and optically attached and aligned to the larger film lightguide. Film cuts are obtained by stamping, laser cutting, mechanical cutting, water jet cutting, local melting or other film processing methods. Preferably, the cutting results in an optically smooth surface to facilitate total internal reflection of light, thereby improving guiding light through the length of the strip. A light source is couple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com