Multistage pressure condenser and steam turbine plant equipped with same

一种冷凝器、压力的技术,应用在蒸汽/蒸气冷凝器、机械设备、蒸汽机装置等方向,能够解决再热效率降低、接触时间变短、距离变短等问题,达到再热效率容易、接触时间增加、抑制增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

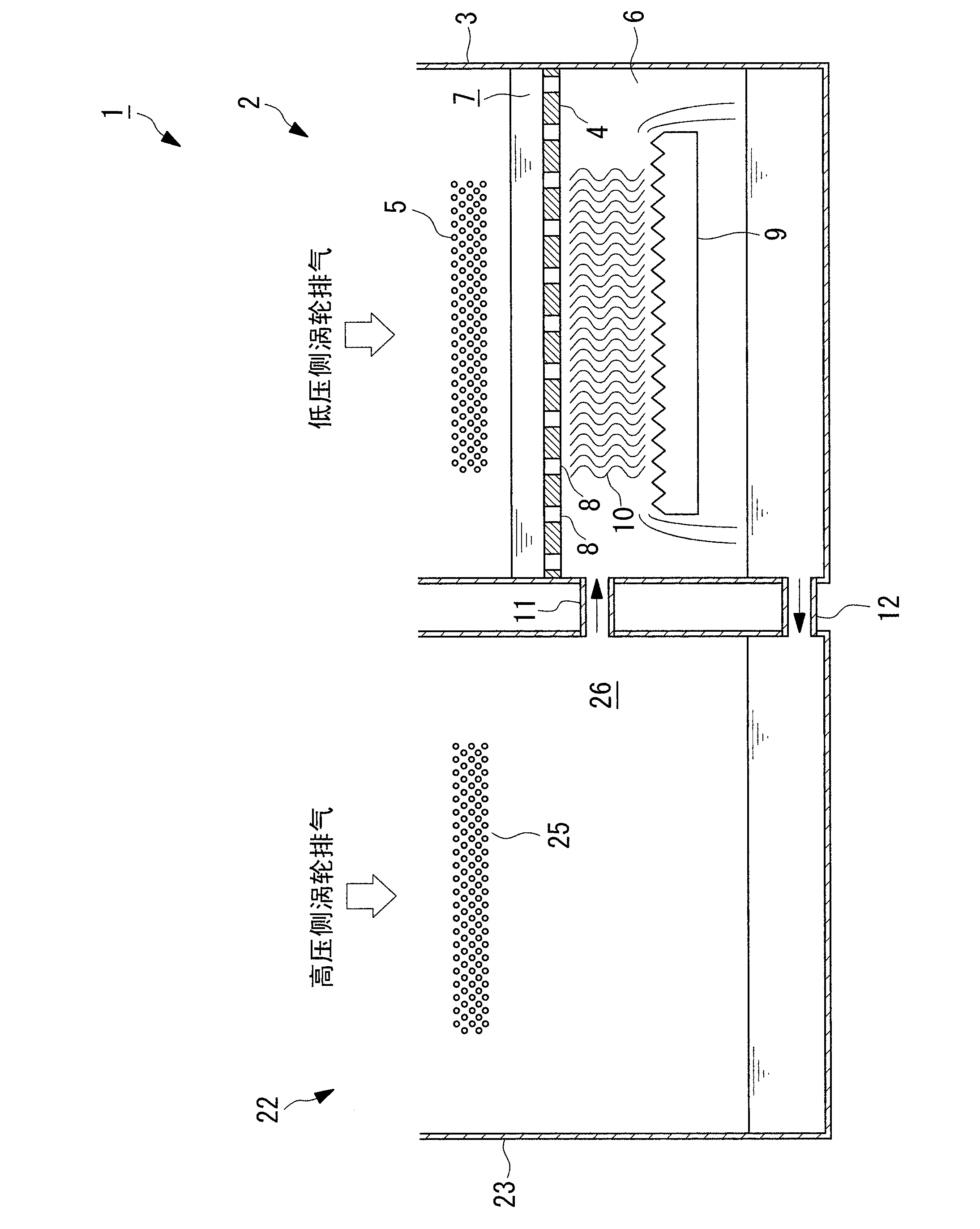

[0054] Below, according to figure 1 About the multi-stage pressure condenser involved in the present invention figure 1 Be explained.

[0055] figure 1 A schematic configuration diagram of the multistage pressure condenser according to this embodiment is shown in .

[0056] The steam turbine equipment (not shown) with the illustrated multi-stage pressure condenser 1 mainly includes: a steam turbine (not shown); a multi-stage pressure condenser 1; a boiler (not shown).

[0057] In the steam turbine plant, the steam expanded and worked by the steam turbine is introduced from the steam turbine into the multi-stage condenser 1, cooled in the multi-stage condenser 1, and condensed to form condensed water. The condensed water condensed in the multi-stage condenser 1 is heated by a feed water heater (not shown), and then supplied to the boiler. The condensed water supplied to the boiler is turned into steam and used as a driving source of the steam turbine.

[0058] Multi-sta...

no. 2 approach

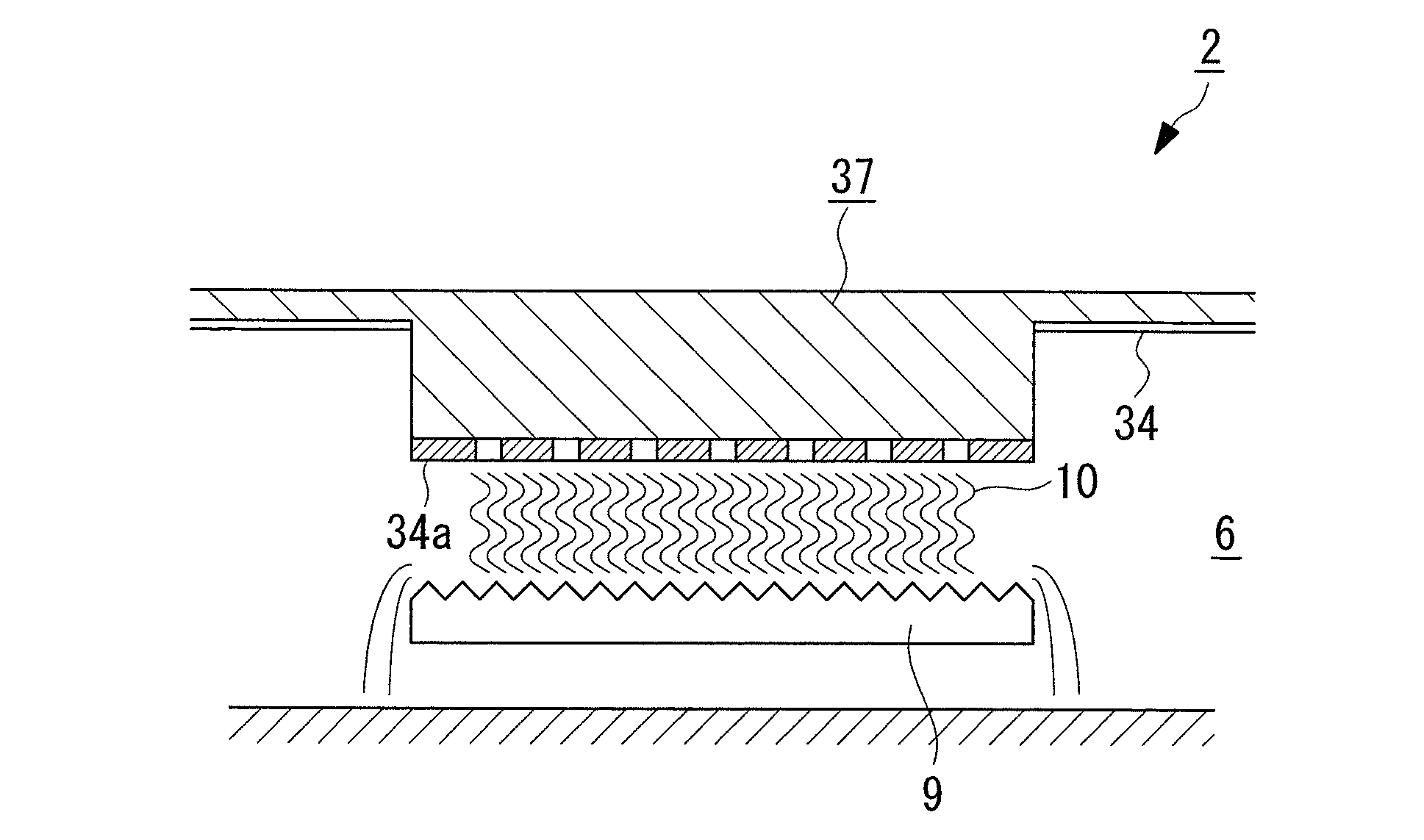

[0088] The multistage pressure condenser of this embodiment and the steam turbine provided therewith are different from the first embodiment in that the distance between the corrugated plates is variable, and the others are the same. Therefore, the same symbols are assigned to the same structures, and descriptions thereof are omitted.

[0089] The distance between the plurality of corrugated plates (plate-shaped members) arranged in parallel to each other is provided so as to be adjustable. For example, by changing the distance between the corrugated plates from approximately 5 mm described in the first embodiment to approximately 2 mm, the thickness of the downflow liquid film of the low-pressure side condensate flowing down between the corrugated plates can be adjusted, and the The flow rate of condensate on the low-pressure side becomes slower.

[0090] Without changing the length of the extending direction between the corrugated plates (the direction in which the low-pres...

no. 3 approach

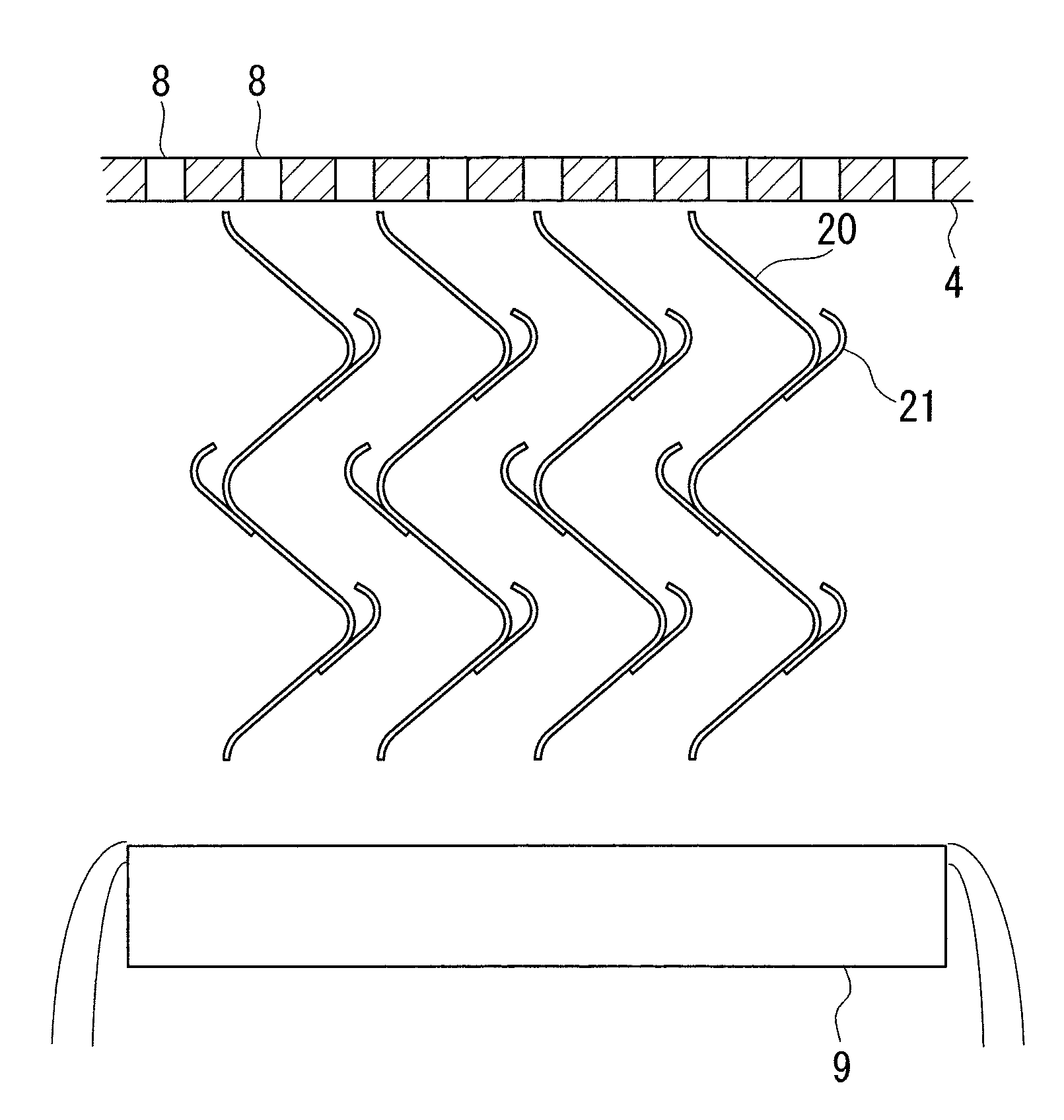

[0094] The multistage pressure condenser of this embodiment and the steam turbine provided therewith are different from the first embodiment in that the corrugated plates have grooves that open toward the low-pressure side condensate flowing down, and are otherwise the same. Therefore, the same symbols are assigned to the same structures, and descriptions thereof are omitted.

[0095] figure 2 A partial enlarged schematic configuration diagram of the low-pressure side condenser of the multi-stage pressure condenser according to the present embodiment is shown in .

[0096] The corrugated plate 20 presents a concavo-convex shape (zigzag shape) in which a plurality of (at least one) valleys are formed alternately in the cross-section of the condensed water on the low pressure side in the direction of flow down, and as figure 2 As shown, the concave-convex convex portion has a groove portion 21 that opens toward the low-pressure side condensate that flows down along the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com