Velocity gradient optimized type planet agitator

A planetary mixer and velocity gradient technology, which is applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of large velocity gradient and uneven distribution of velocity field of stirring blade motion, and achieve long service life, processing and manufacturing. And the effect of convenient disassembly and assembly, accurate transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

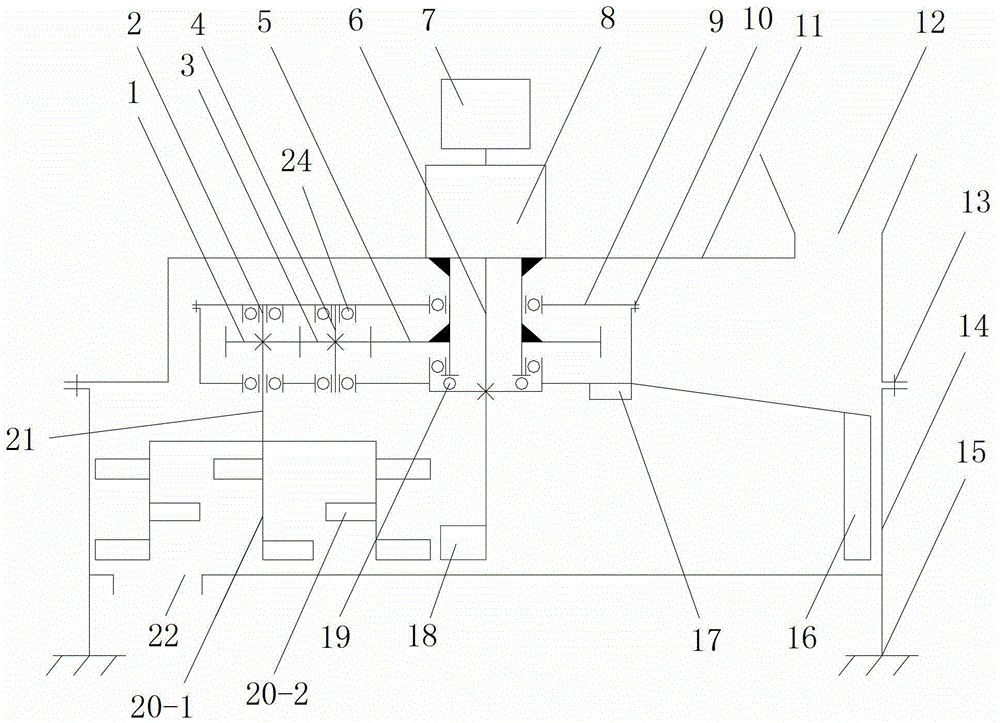

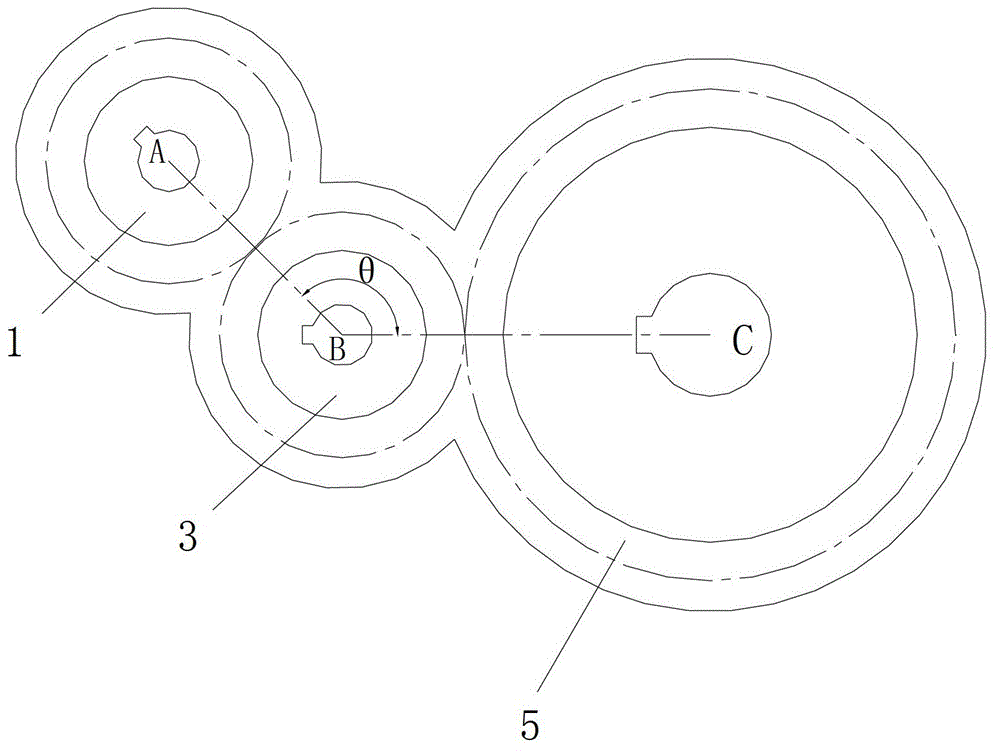

[0042] Such as figure 1 , figure 2 As shown, the present invention includes a casing, a transmission device and a stirring shaft 21 installed in the casing, the casing is arranged horizontally, and the stirring shaft 21 is arranged vertically and its number is one or more indivual. The transmission device includes a box body 9 driven by a drive mechanism to continuously rotate horizontally, a sun gear 5 and a transmission gear set installed in the box body 9, the box body 9 is connected with the drive mechanism, and the transmission gear set The number is the same as the number of the stirring shaft 21; the transmission gear set includes the first planetary gear 3 installed in the case 9 through the installation shaft 4 and the second planetary gear 1 coaxially sleeved on the stirring shaft 21, the The first planetary gear 3 , the second planetary gear 1 and the sun gear 5 are arranged on the same horizontal plane, the first planetary gear 3 meshes with the sun gear 5 , and...

Embodiment 2

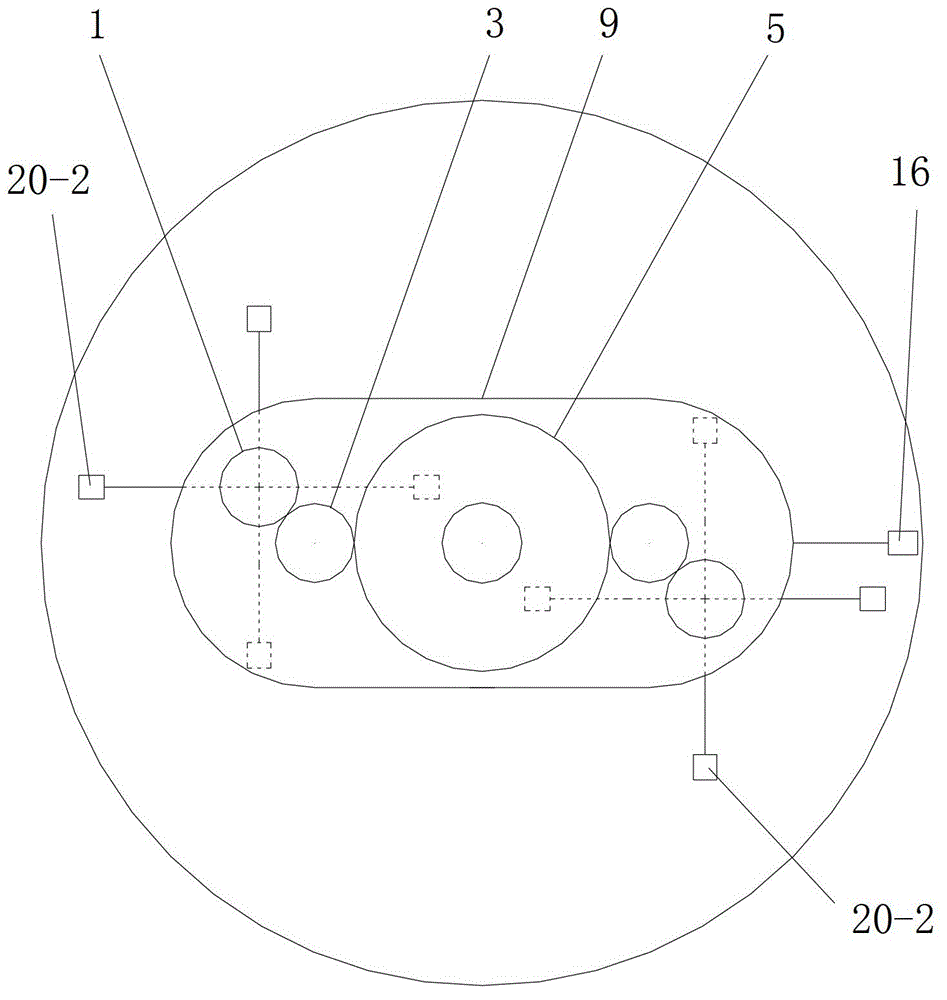

[0074] In this example, if image 3 As shown, the difference from Example 1 is that the number of the stirring shaft 21 and the transmission gear set is two, the shape of the box body 9 is a rounded rectangle, and the two stirring shafts 21 are respectively installed On the two transmission gear sets, and the two stirring shafts 21 and the two transmission gear sets are respectively symmetrically installed on the left and right sides of the power output shaft one 6, and the power output shaft one 6 is arranged on the box The middle part of body 9. During actual processing, the quantities of the stirring shaft 21 and the transmission gear sets can be adjusted respectively according to actual needs.

[0075] When the number of the stirring shaft 21 and the transmission gear set is multiple, the structure and size of the multiple transmission gear sets are the same, and the multiple stirring shafts 21 and the multiple transmission gear sets are all the same. Evenly arranged alo...

Embodiment 3

[0079] In this example, if Figure 4 As shown, the difference from Embodiment 2 is that the number of the stirring shaft 21 and the transmission gear set is three, and the three stirring shafts 21 and the three transmission gear sets are evenly arranged along the circumferential direction. , and the three agitating shafts 21 are installed on three of the plurality of transmission gear sets respectively.

[0080] In this embodiment, the structures, dimensions, connections and working principles of the remaining parts are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com