Tower crane hoisting and speed control system and speed control method thereof

A control system and technology for tower cranes, applied in the field of tower crane hoisting speed regulation control and tower crane hoisting speed regulation control system, can solve the problems that the system efficiency cannot be significantly improved, the motor power cannot be fully utilized, and can avoid unpredictability. stability, improve efficiency, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

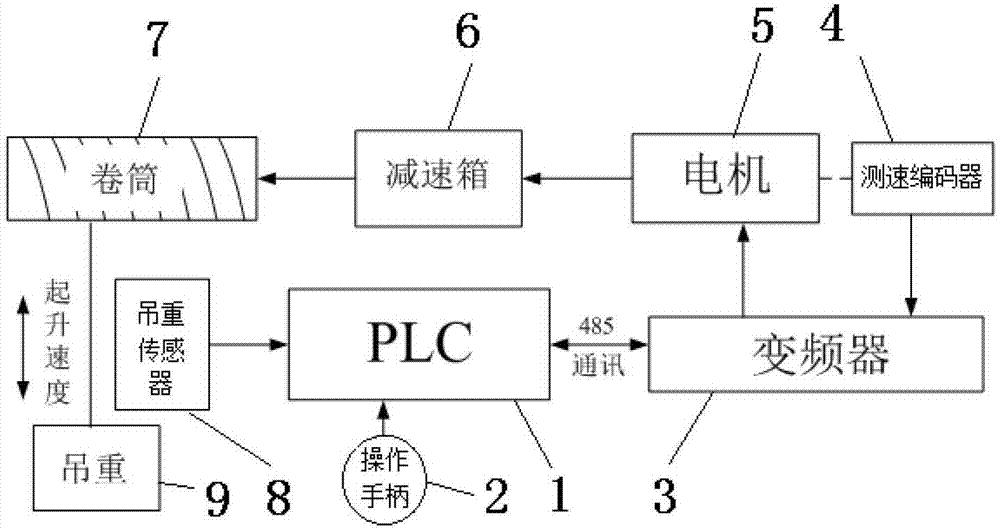

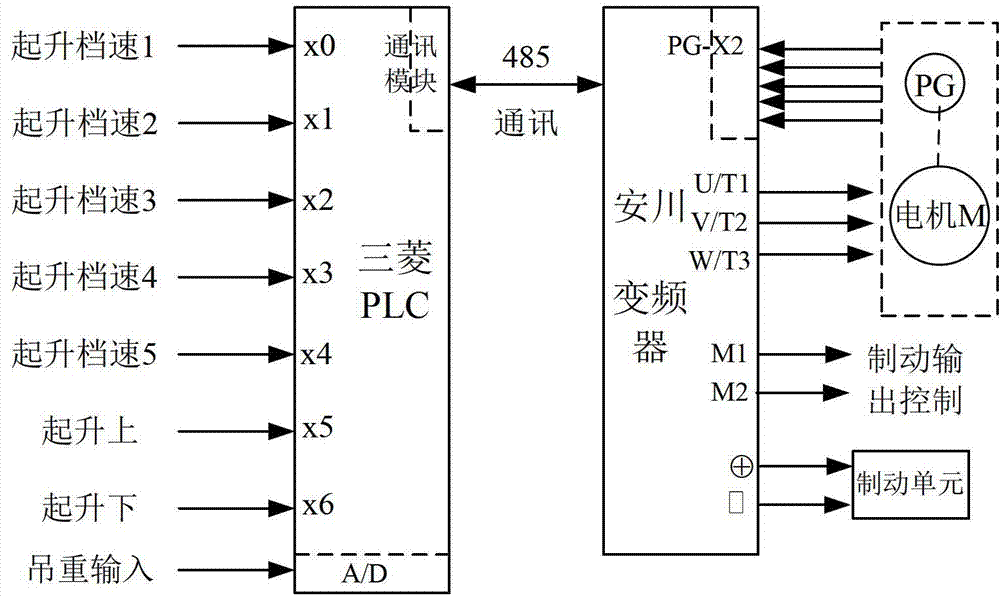

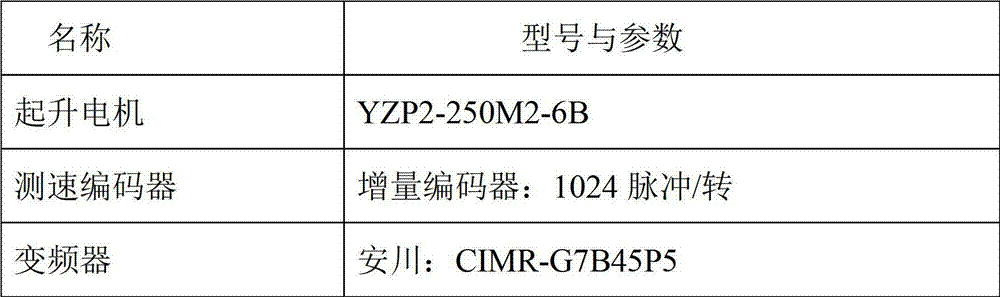

[0040] refer to figure 2 , Take the hoisting speed regulation of a 16-ton tower crane as an example, PLC1 uses Mitsubishi PLC, and frequency converter 3 uses Yaskawa frequency converter. The tower crane hoisting control system configuration is as follows:

[0041]

[0042]

[0043] The setting frequency of the tower crane hoisting 5-speed inverter is: 5Hz, 15Hz, 45Hz, 80Hz, 110Hz; corresponding to the above-mentioned hoisting mechanism, the hoisting line speed under the tower crane 2 rope is as follows:

[0044] Gear frequency (Hz)

5

15

45

80

110

2 Rope speed (m / min)

3.9

11.7

35.1

62.4

85.8

[0045] According to the characteristics of the motor, the current hoisting weight Q≤4.8 tons, the system can run at 110Hz;

[0046] The current hoisting weight is 4.8 tons ≤ Q ≤ 8 tons, and the system can run between 80Hz and 110Hz;

[0047] For ordinary hierarchical control, when the current hoisting weight Q≤6 tons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com