Double-modified prepared medium-voltage water-tree-retardant polyethylene insulating material

A polyethylene insulating material, double modification technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of shortened service life of cables, and achieve the effect of accelerating the crystallization speed, inhibiting the growth process, and inhibiting the initiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

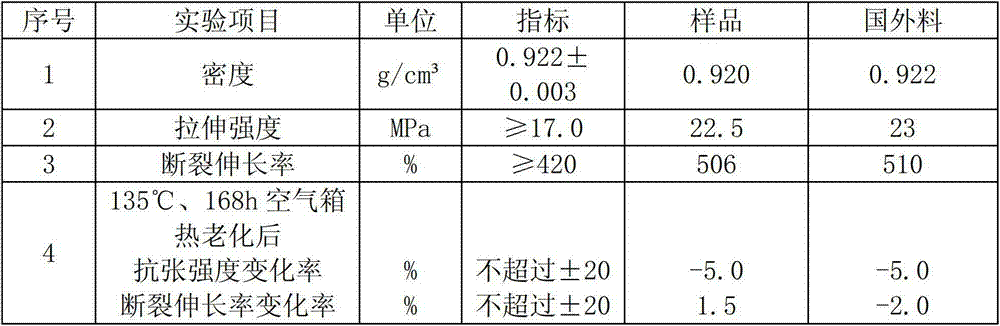

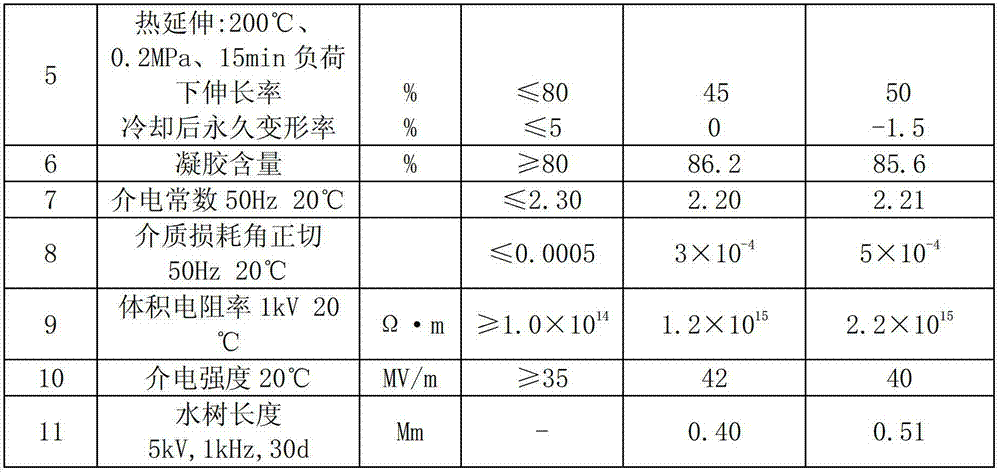

Examples

Embodiment 1

[0038] The composite reagent for inhibiting water tree initiation and growth of the present embodiment is made up of the following components in parts by weight:

[0039] Dibenzylidene sorbitol 0.3 parts,

[0040] Ethylene-vinyl acetate copolymer 3 parts,

[0041] 10 parts of metallocene elastomer;

[0042] 100 parts by weight of low-density polyethylene (preferably having a melt index of 2.0 to 3.0 g / 10min), 0.1 parts by weight of antioxidant 300, 0.1 parts by weight of antioxidant 168, 2.5 parts by weight of DCP and the above compounding The reagents are fed into the reciprocating single-screw extruder and the single-screw extruder by using a high-precision weight-loss feeding system, and are mixed, sheared, and plasticized at 100-110°C in the reciprocating single-screw extruder. Then extrude in a single-screw extruder, granulate with spray granulation, after cooling, centrifugal dehydration, boiling drying, and realize automatic packaging by an automatic weighing and pack...

Embodiment 2

[0045] The composite reagent for inhibiting water tree initiation and growth of the present embodiment is made up of the following components in parts by weight:

[0046] 0.2 parts of sorbitol,

[0047] 3 parts of maleic anhydride grafted ethylene vinyl acetate copolymer,

[0048] Metallocene polyethylene 5 parts;

[0049] 100 parts by weight of low-density polyethylene (preferably having a melt index of 2.0 to 3.0 g / 10min), 0.2 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant DLTP, 2.5 parts by weight of DCP and the above compounding The reagents are fed into the reciprocating single-screw extruder and the single-screw extruder by using a high-precision weight-loss feeding system, and are mixed, sheared, and plasticized at 100-110°C in the reciprocating single-screw extruder. Then extrude in a single-screw extruder, granulate with spray granulation, after cooling, centrifugal dehydration, boiling drying, and realize automatic packaging by an automatic w...

Embodiment 3

[0052] The composite reagent for inhibiting water tree initiation and growth of the present embodiment is made up of the following components in parts by weight:

[0053] 1,3: 0.3 parts of 2,4-bis(3,4-dimethylbenzylidene)sorbitol

[0054] 1 part of medium density polyethylene graft,

[0055] 10 parts of metallocene elastomer;

[0056] 100 parts by weight of low-density polyethylene (preferably having a melt index of 2.0 to 3.0 g / 10min), 0.1 parts by weight of antioxidant 300, 0.3 parts by weight of antioxidant DLTP, 2.5 parts by weight of BPO and the above-mentioned compounding The reagents are fed into the reciprocating single-screw extruder and the single-screw extruder by using a high-precision weight-loss feeding system, and are mixed, sheared, and plasticized at 100-110°C in the reciprocating single-screw extruder. Then extrude in a single-screw extruder, granulate with spray granulation, after cooling, centrifugal dehydration, boiling drying, and realize automatic pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com