Crosslinked polyethylene cable insulating material with water treeing resisting function and preparation method of material

A cross-linked polyethylene, cable insulation technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problem of serious water tree phenomenon in cables, achieve superior water tree resistance, excellent strength and toughness, and The effect of superior water tree performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

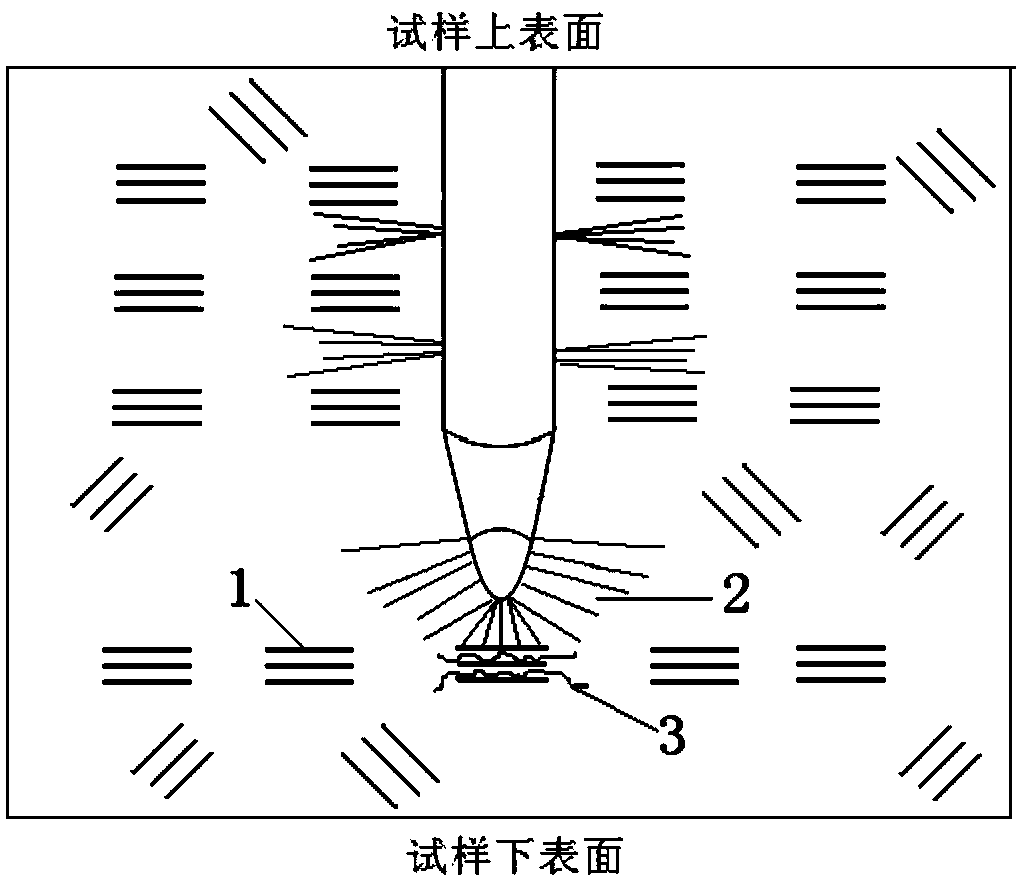

Image

Examples

Embodiment 1

[0038]Example 1: Using 80 parts of low-density polyethylene, 20 parts of anti-water tree modifier, 2 parts of dicumyl peroxide (DCP) (crosslinking agent), 4,4'-thiobis(6-tetra butyl m-cresol) 0.2 parts (antioxidant). The mass percent of each component of the anti-water tree modifier is: 80% of low-density polyethylene, 10% of clay, 9.9% of ethylene-vinyl acetate copolymer, and 0.1% of stearylamine.

Embodiment 2

[0039] Embodiment 2: adopt 85 parts of low-density polyethylene, 15 parts of anti-water tree modifiers, 1.3 parts of dicumyl peroxide (DCP) (crosslinking agent), tetrakis [β-(3.5-di-tert-butyl- 0.4 parts of 4-hydroxyphenyl) propionic acid] pentaerythritol ester (antioxidant), 0.2 parts of 1026 rheology modifier. The mass percentage of each component of the anti-water tree modifier is: polyolefin elastomer 75%, montmorillonite 15%, ethylene-ethyl acrylate 8.5%, lauryl ammonium salt 1%, dihexadecyl ammonium Salt 0.5%.

Embodiment 3

[0040] Embodiment 3: Adopt 85 parts of low-density polyethylene pellets, 15 parts of anti-water tree modifiers, 1.5 parts of di-tert-butyl peroxide (DTBP) (cross-linking agent), 0.2 parts of benzoyl peroxide (cross-linking agent) joint auxiliary agent), 0.1 part of diethylaminopropylamine (crosslinking auxiliary agent), 0.6 part of tris[2.4-di-tert-butylphenyl] phosphite (antioxidant), 0.1 part of FX-59240 (rheology modification agent). The mass percent of each component of the anti-water tree modifier is: 85% of low-density polyethylene, 10% of montmorillonite, 4.5% of ethylene-vinyl acetate copolymer, and 0.5% of stearylamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com