Water-tree-resistant polyethylene insulation nano-composite material and preparation method thereof

A nano-composite material and polyethylene insulation technology, which is applied in the field of water-tree-resistant polyethylene insulation nano-composite materials and its preparation, can solve problems such as difficult resin matrix uniform dispersion, difficult resin matrix compatibility, and easy aggregation of inorganic nanoparticles , to achieve excellent water tree resistance, good compatibility, and not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

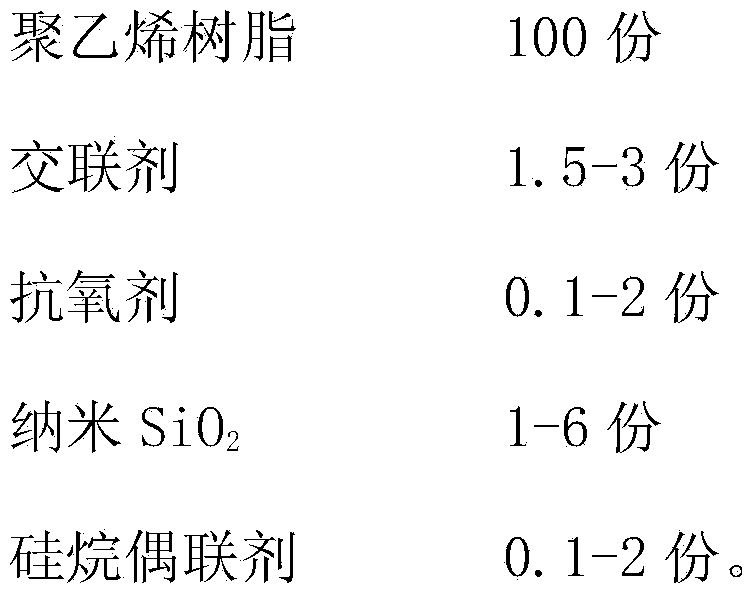

[0023] Described a kind of anti-water tree polyethylene insulating nanocomposite material, it comprises the composition and weight part are:

[0024]

[0025] In a preferred embodiment, the silane coupling agent is vinyltrimethoxysilane,

[0026] In a preferred embodiment, the cross-linking agent is one or a mixture of dicumyl peroxide (DCP) and benzoyl peroxide (BPO).

[0027] In a preferred embodiment, the antioxidant is a mixture of one or more of antioxidant 300, antioxidant 1010, antioxidant 1024 or antioxidant 697, and a mixture of one or more of antioxidants. 300 is a typical thiobisphenol antioxidant. Because of its special structure, it has the dual functions of free radical terminator and hydroperoxide decomposer, and shows excellent synergistic effect when used with carbon black, which is incomparable with commonly used antioxidants; Agent 1010 has excellent antioxidant properties for polypropylene and polyethylene. It can effectively extend the service life o...

Embodiment 2

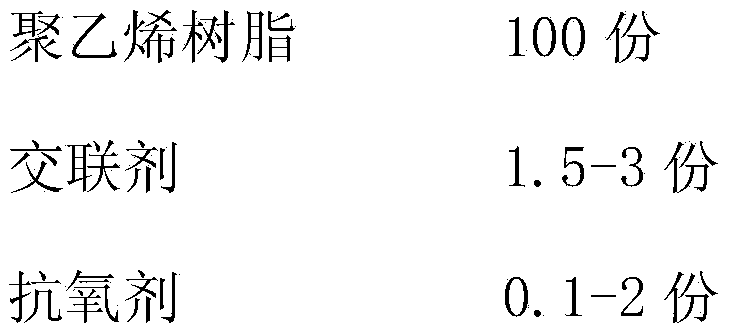

[0030] The water-tree-resistant polyethylene insulating nanocomposite material of the present invention comprises the following components and parts by weight:

[0031]

[0032] In a preferred embodiment, the silane coupling agent is vinyltrimethoxysilane.

[0033] In a preferred embodiment, the cross-linking agent is one or a mixture of dicumyl peroxide and benzoyl peroxide.

[0034] In a preferred embodiment, the antioxidant is a mixture of one or more of antioxidant 300, antioxidant 1010, antioxidant 1024 or antioxidant 697, and a mixture of one or more of antioxidants. 300 is a typical thiobisphenol antioxidant. Because of its special structure, it has the dual functions of free radical terminator and hydroperoxide decomposer, and shows excellent synergistic effect when used with carbon black, which is incomparable with commonly used antioxidants; Agent 1010 has excellent antioxidant properties for polypropylene and polyethylene. It can effectively extend the service...

Embodiment 3

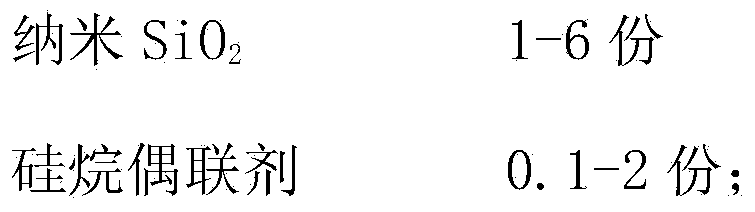

[0037] The water-tree-resistant polyethylene insulating nanocomposite material of the present invention comprises the following components and parts by weight:

[0038]

[0039] In a preferred embodiment, the silane coupling agent is vinyltrimethoxysilane.

[0040] In a preferred embodiment, the cross-linking agent is one or a mixture of dicumyl peroxide and benzoyl peroxide.

[0041] In a preferred embodiment, the antioxidant is a mixture of one or more of antioxidant 300, antioxidant 1010, antioxidant 1024 or antioxidant 697.

[0042] A cable comprising the above-mentioned water-tree-resistant polyethylene insulating nanocomposite material, and its partial use and full use in the cable fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com