Evaporator baffle deformation-preventing structure in vacuum aluminizing equipment

A technology of vacuum aluminum plating and evaporator, which is applied in the direction of vacuum evaporation plating, sputtering plating, ion implantation plating, etc. It can solve problems such as jamming, deformation, arching downwards, and inability to remove, etc., to reduce Effects of longitudinal expansion, weight reduction, and thermal deformation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

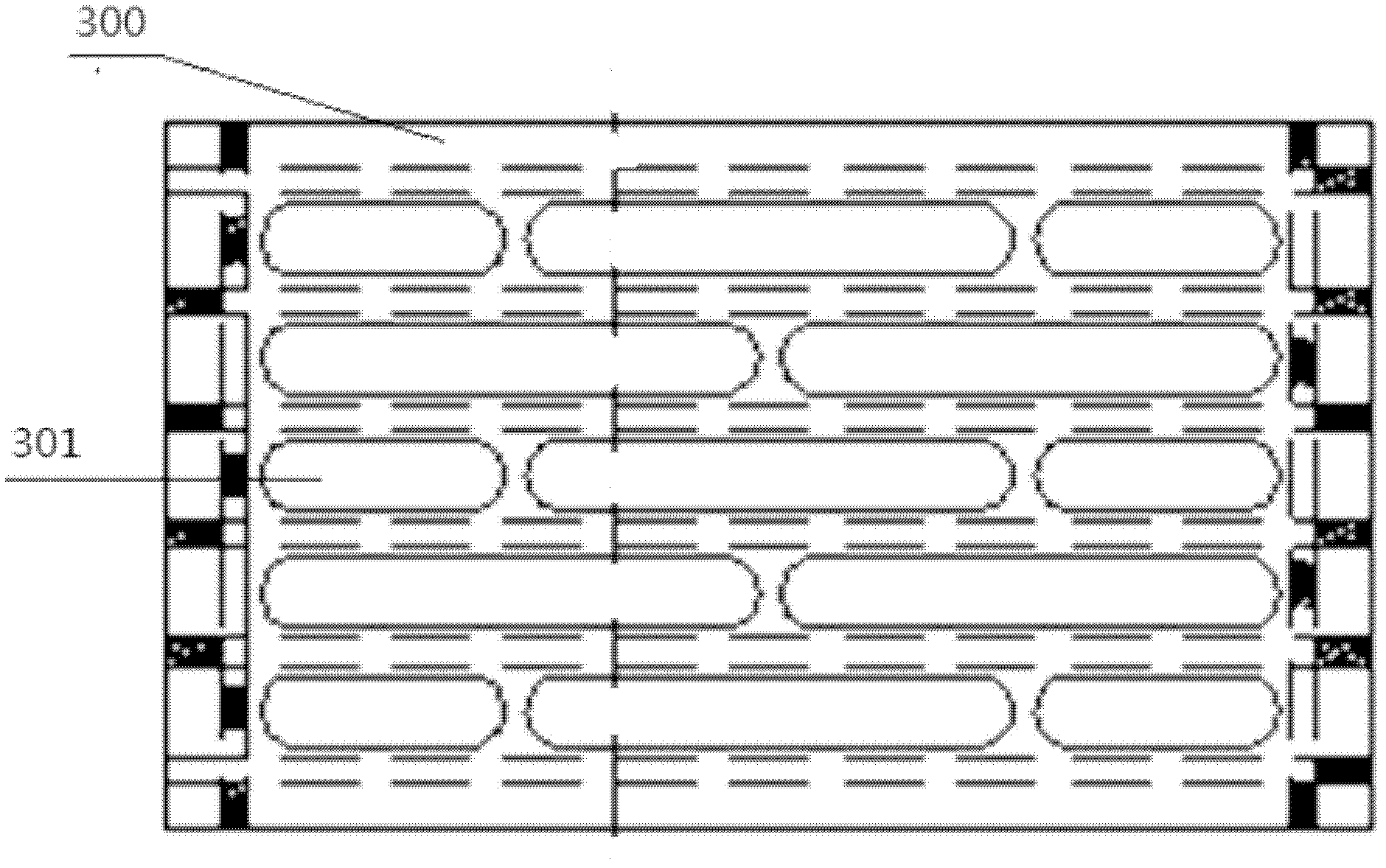

[0011] like figure 1 As shown, the anti-deformation structure of the evaporator baffle plate in the vacuum aluminum plating equipment of the present invention includes a body 300 and at least two rows of milling grooves 301. The milling grooves 301 are on the body 300, and each row of milling grooves 301 is parallel to each other. The shape of the milling grooves 301 is Oval.

[0012] The structure of the main body is a structure similar to a plate stiffener. On the premise of not destroying the circulating waterway, the present invention mills grooves on the main body, which reduces the material used for the baffle and enhances the water cooling effect (from about 200°C to about 120°C), which reduces the weight of the body, reduces the longitudinal expansion, and reduces the deformation caused by heat and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com