Hot melting-resistant structure for guide steel wire of silicon core furnace

A silicon core furnace and oriented technology, applied in self-regional melting method, crystal growth, single crystal growth, etc., can solve the problems of short service life of high-frequency coils, affecting production progress, shutdown and replacement, etc., to prevent drawn hole contact The probability of exposure, the probability of reduced exposure, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

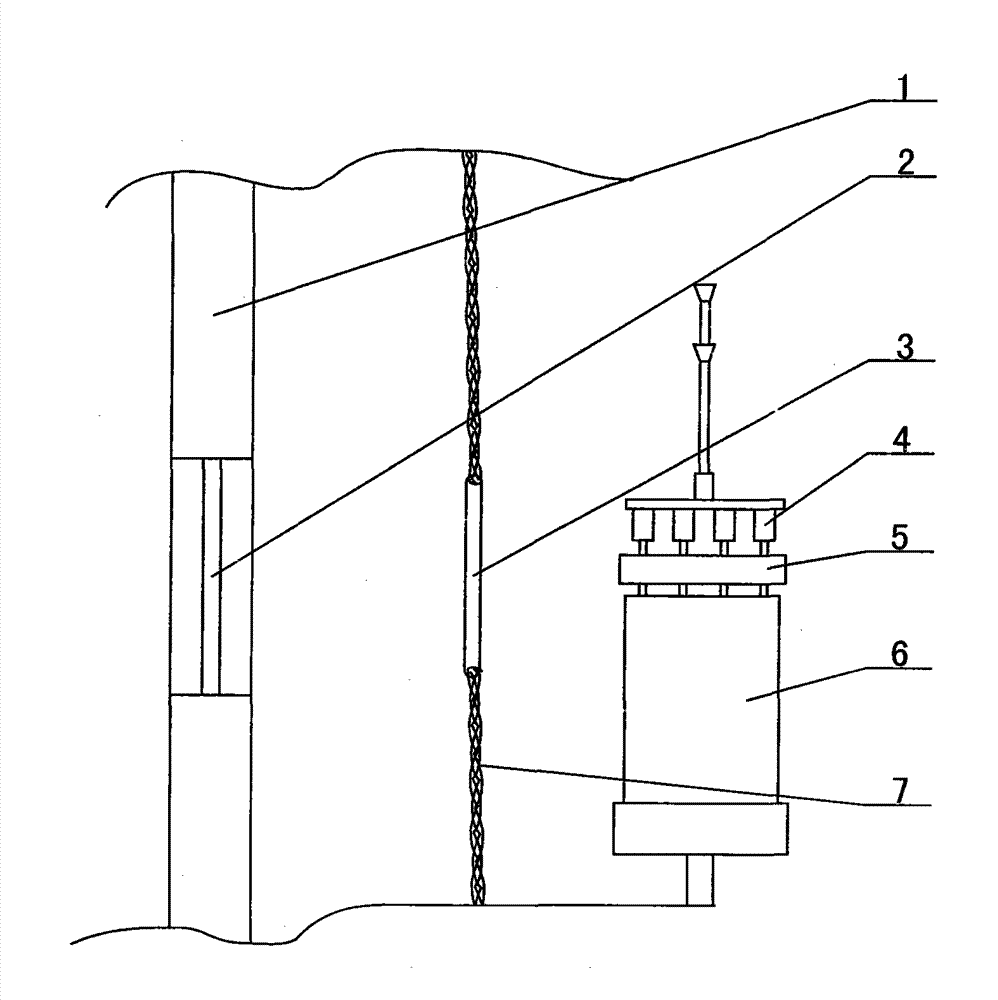

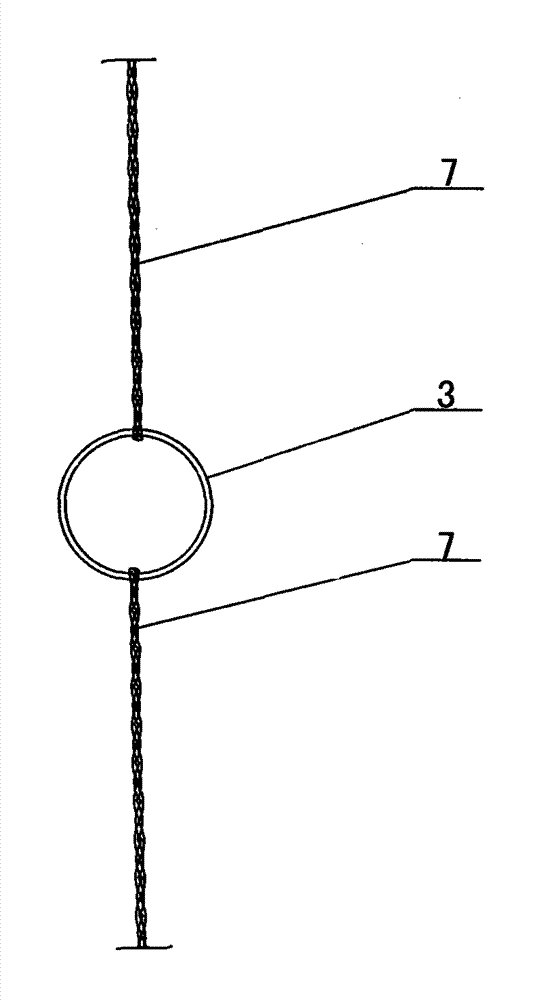

[0015] Attached figure 1 , 2 The structure disclosed in, the heat-melting prevention structure of the silicon core furnace guide steel wire includes a silicon core furnace furnace body 1, on the guide steel wire 7 between the observation window 2 on the wall of the silicon core furnace furnace body 1 and the high-frequency coil 5 A circular or polygonal ring 3 is provided. The center of the ring 3 corresponds to the high-frequency coil 5, and the guide wire 7 is disconnected between the observation window 2 and the high-frequency coil 5. The upper and lower sides of the ring 3 The two ends of the guide wire 7 which are disconnected are respectively connected to the two ends.

[0016] To implement the anti-hot-melt structure of the silicon core furnace guide steel wire of the present invention, the use process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com