Aluminum perforated sound-absorption and insulation plate

A technology of sound absorption and perforated panels, applied in noise absorption devices, buildings, etc., can solve the problems of increasing the amount of materials and increasing the weight of barrier panels, and achieve the effects of reasonable structure, material saving and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and embodiments.

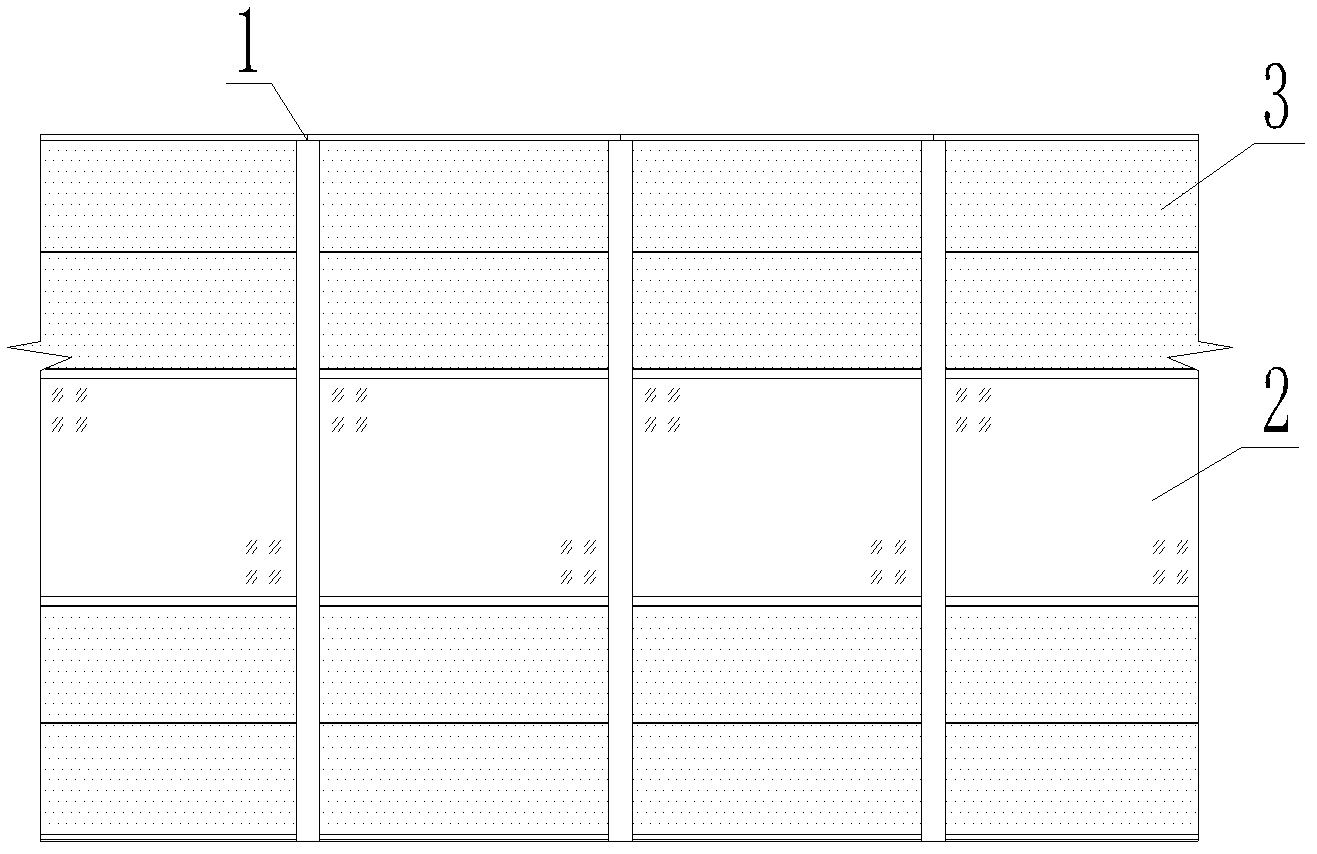

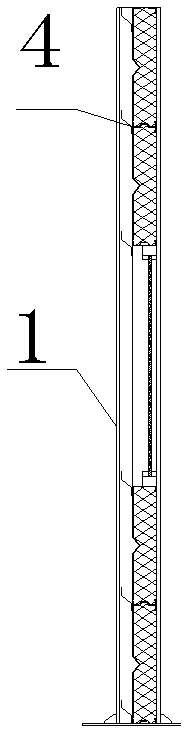

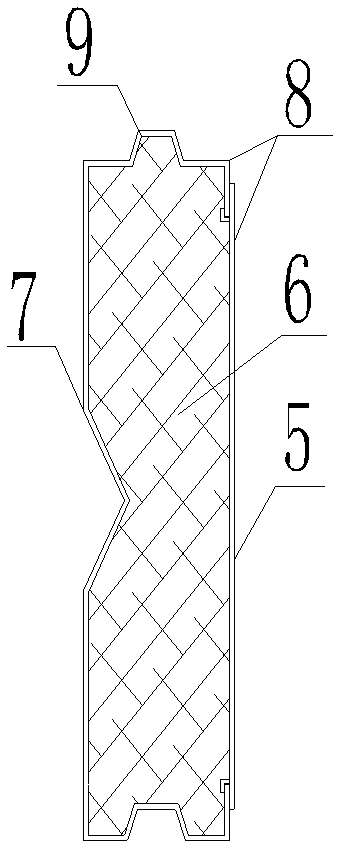

[0018] like figure 1 , figure 2 and image 3 As shown, the aluminum perforated sound absorption and sound insulation board of the present invention includes a steel column 1, in which the middle part of the steel column 1 is a transparent PC board 2, and the upper and lower parts are aluminum perforated plates 3, which pass through Z-shaped spring fasteners 4 Pressed connection with the steel column 1; the aluminum perforated plate 3 includes an aluminum perforated panel 5, a centrifugal glass wool 6 and a V-shaped galvanized steel back plate 7, the aluminum perforated panel 5 and the V-shaped galvanized steel The upper and lower connecting parts of the frame 8 composed of the zinc steel back plate 7 are embedded concave-convex groove structures 9; the perforation rate of the aluminum perforated panel 5 is greater than 25%; the aluminum perforated pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com