Mine single hydraulic prop

A single hydraulic prop, mine-used technology, applied in the direction of props/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of low joint strength, fear of collapse of live posts, slow return of live posts, etc., to achieve enhanced combination Strength, reduce maintenance chance, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

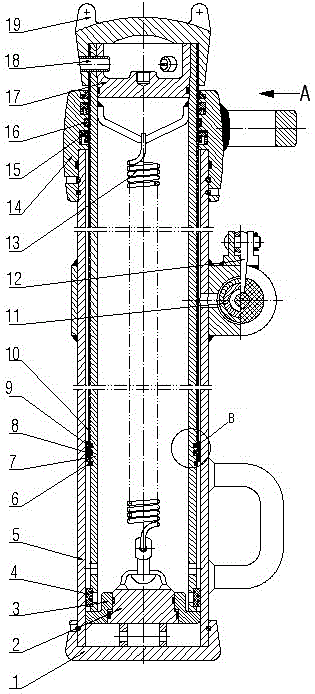

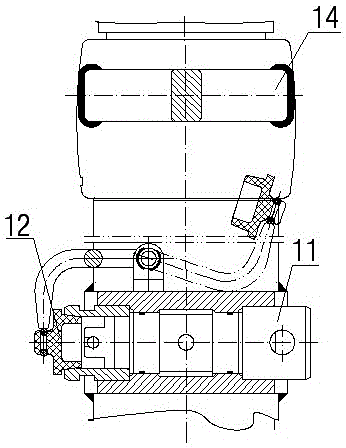

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

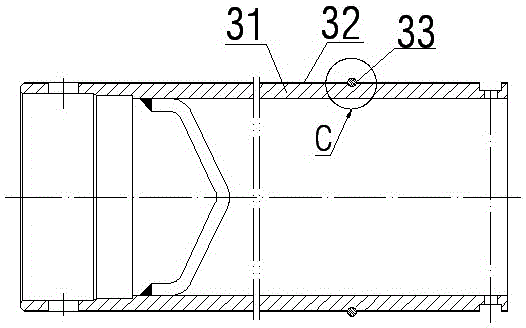

[0022] refer to figure 1 And attached Figure 5 , shows a schematic diagram of the connection structure between the live post and the sleeve in the prior art, wherein the live post 31 is covered with a stainless steel sleeve 32, and a limit ring 33 is provided at the lower end of the live post 31. In order to improve the connection between the stainless steel sleeve 32 and the live post 31 For bonding strength, an adhesive, such as polyurethane adhesive, is applied between the stainless steel sleeve 32 and the live post 31 . Although this technical scheme also protects the live column 31 by adding a stainless steel sleeve 32, the bonding strength between the stainless steel cover 32 and the live column 31 is low, and it is easy to cause falling off during use, which greatly reduces the use of the hydraulic prop. life.

[0023] The specific structure of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com