Slag removing machine for ore-smelting furnace

A technology of submerged arc furnace and slag scraper, which is applied to furnaces, furnace components, mechanical cleaning, etc., can solve the problems of high price, no application of submerged arc furnace for smelting slag scraping, and large equipment, so as to reduce personal safety hazards and improve Labor-intensive, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

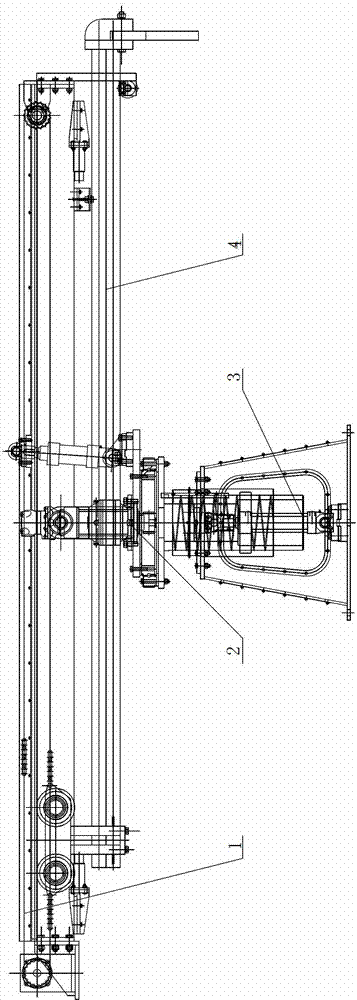

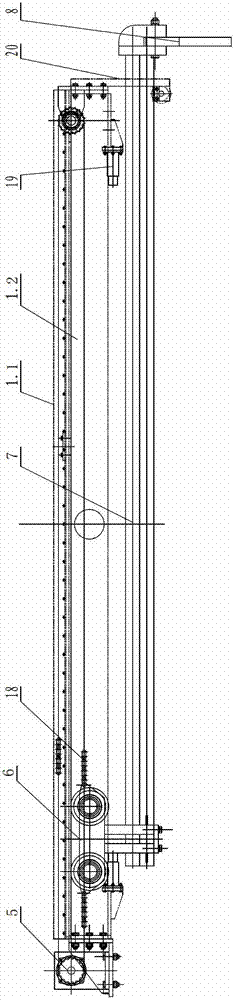

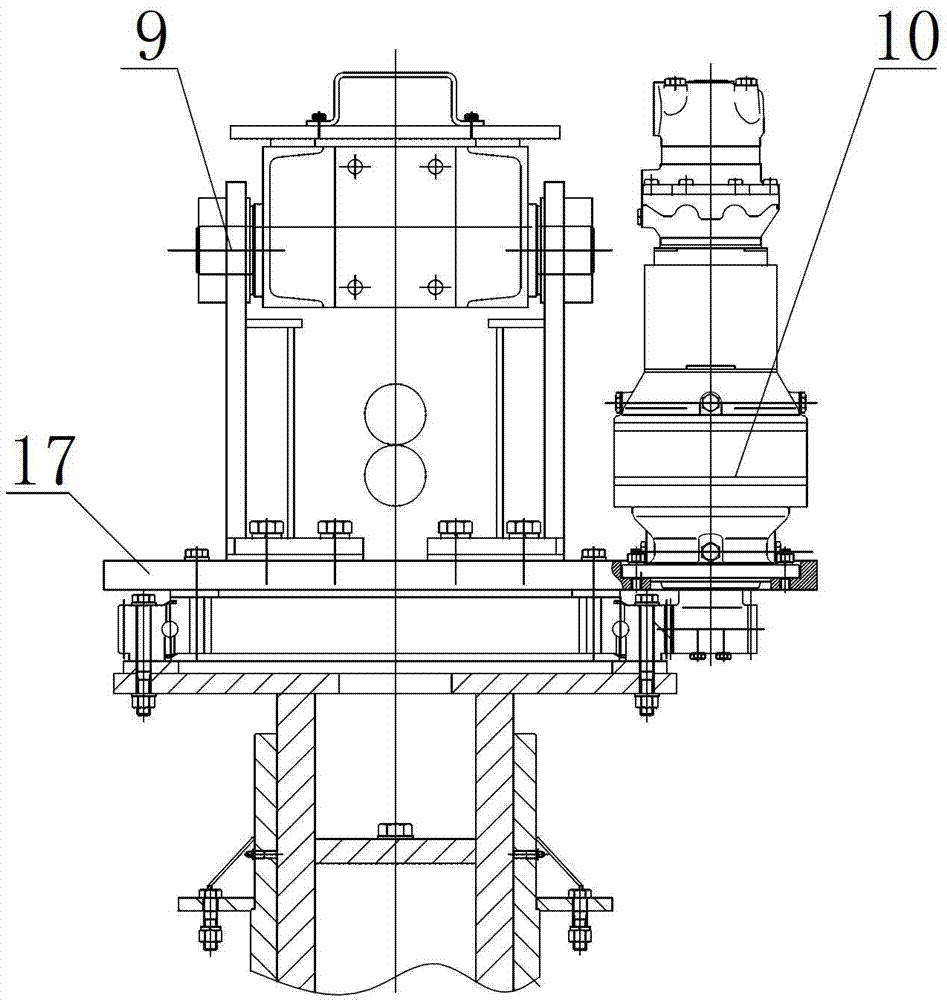

[0027] Such as figure 1 The shown slag removal machine for submerged arc furnace includes: slideway frame device 1, pitching device 2, lifting device 3 and slag removal device 4; lifting device 3 includes: base 13, lifting cylinder 14, fixed platform 15 and lifting platform 16. The fixed platform 15 is fixed on the base 13, the lifting cylinder 14 is set inside the fixed platform 15, and the bottom and the base 13 are fixed on the upper end and the fixed platform 15 is fixed, the lifting cylinder 14 protrudes from the fixed platform 15, and the upper end surface is fixed with a lift Platform 16, a slewing bearing 12 is fixed on the upper end of the lifting platform 16, and is detachably and fixedly connected with the outer ring gear of the slewing bearing 12, and a slewing platform 17 is fixed on the upper end surface of the inner ring of the slewing bearing 12 such as Figure 5 As shown, adopt this structure to realize the lifting of the lifting platform 16 by the lifting cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com