Lead slag salvaging device

A lead slag and chute technology, which is applied in the field of mining and metallurgy equipment, can solve problems such as poor working conditions, impact on the quality of lead ingots, and worker hazards, and achieve the effects of meeting the requirements of slag removal, stable slag removal process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

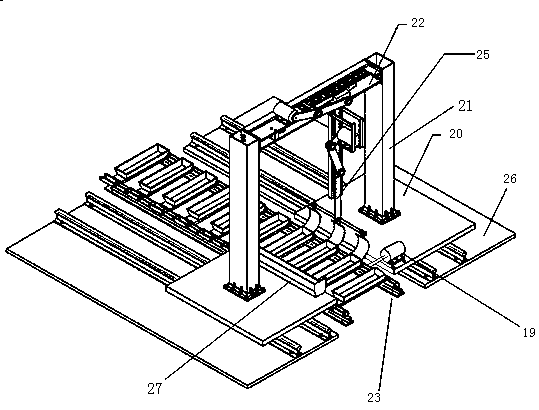

[0022] Embodiment 1: as Figure 1-4 As shown, a lead slag removal device includes a chute mechanism 22, a slag removal arm 25, a synchronous motor 19, a moving slide 20, a support column 21, a claw hook 24, a base 26 and a slag storage box 27;

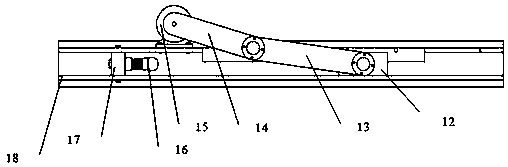

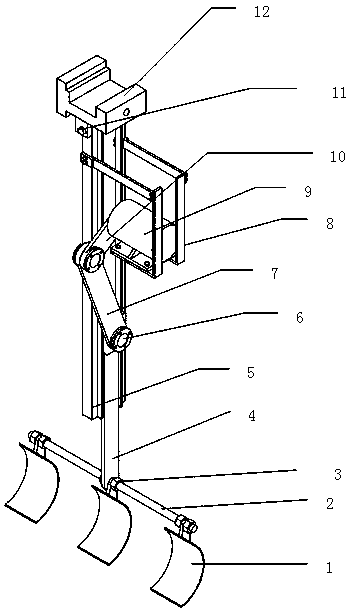

[0023] Wherein the chute mechanism 22 is installed on the mobile slide plate 20 through the support column 21, the mobile slide plate 20 is installed on the base 26 with guide rail, the slag removal arm 25 is connected with the chute mechanism 22, and is installed on the mobile slide plate 20 to synchronize the movement of the motor 19 The claw hook 24 is driven to catch the moving production line, and the movable slide plate 20 moves together with the production line. The movement of the drive motor II 15 in the chute mechanism 22 drives the slag removal arm 25 to move along the slag river on the roller 23, and the drive motor Ⅰ9 in the slag removal arm 25 The motion drives the slag removal arm 25 to move up and down, and the slag rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com