Method and device for detecting solid fraction and final stage of solidification of continuously cast slab

A technology of solidification end and detection method, which is applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of poor accuracy, inability to detect the solid phase ratio of continuous casting slabs, and inability to measure continuously for a long time, so as to improve detection accuracy, The effect of convenient and quick repeated online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0045] Firstly, the specific implementation of the method for detecting the solid phase ratio and solidification end of the continuous casting slab of the present invention will be described in detail.

[0046] The detection method of the continuous casting slab solid phase ratio and solidification end of the present embodiment comprises the following steps:

[0047] 1) Vibration excitation is applied to the continuous casting billet 1, and the continuous casting billet 1 undergoes elastic deformation under the action of the vibration excitation;

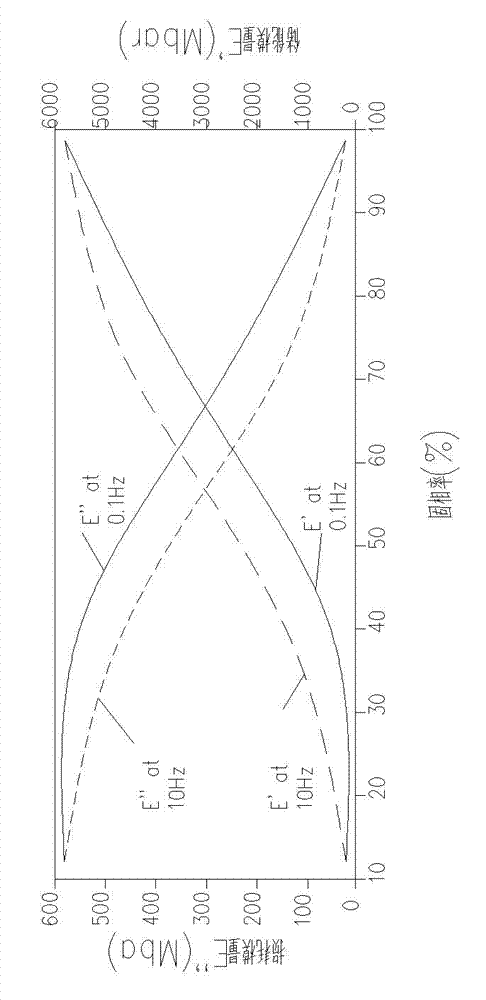

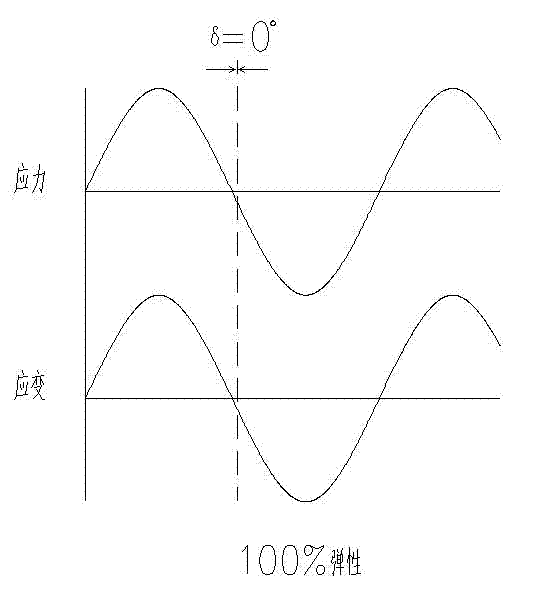

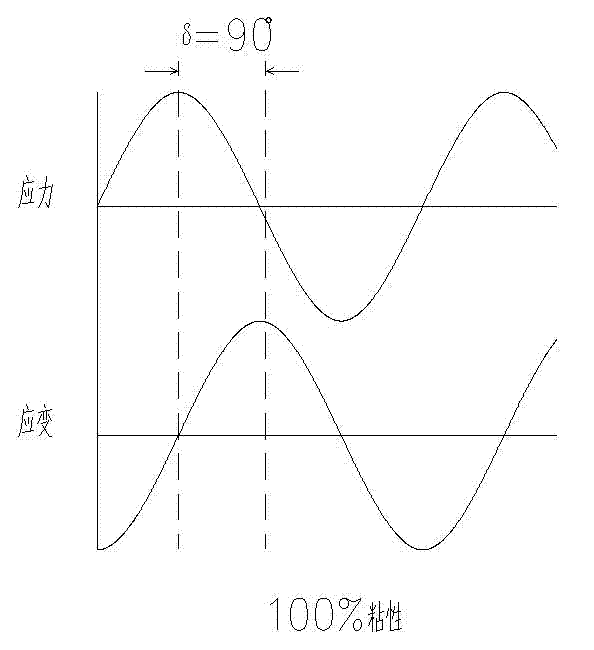

[0048] 2) After the continuous casting slab 1 resonates with the oscillation excitation, measure the strain of the elastic deformation of the continuous casting slab 1, the stress load applied to the continuous casting slab 1 by the oscillation excitation, and the stress / Strain phase difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com