Testing method of plugging rate of repeated fracturing plugging agent

A technology for repeated fracturing and testing methods, which is applied in the fields of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., and can solve problems such as improper selection of materials, decline in fluid production index, and low water absorption capacity of water injection wells. To achieve the effect of accurate test results and simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The test method of the plugging rate of the repeated fracturing plugging agent involved in the present invention, its concrete steps are as follows:

[0037] (a) preparing refracturing plugging agent for subsequent use;

[0038] (b) Splitting the selected rock core to create an artificial fracture;

[0039] (c) Spread a layer of granular material on the fracture surface to simulate fracturing fractures;

[0040] (d) Inject the refracturing plugging agent into the simulated fracturing fractures and let it stand for a period of time;

[0041] (e) Inject liquid, measure permeability, and calculate plugging rate.

[0042] In the step (b), the core is split axially.

[0043] In the step (c), the particulate matter is quartz sand.

[0044] In the step (d), the standing time is 12h.

[0045] In the step (e), the liquid is clear water.

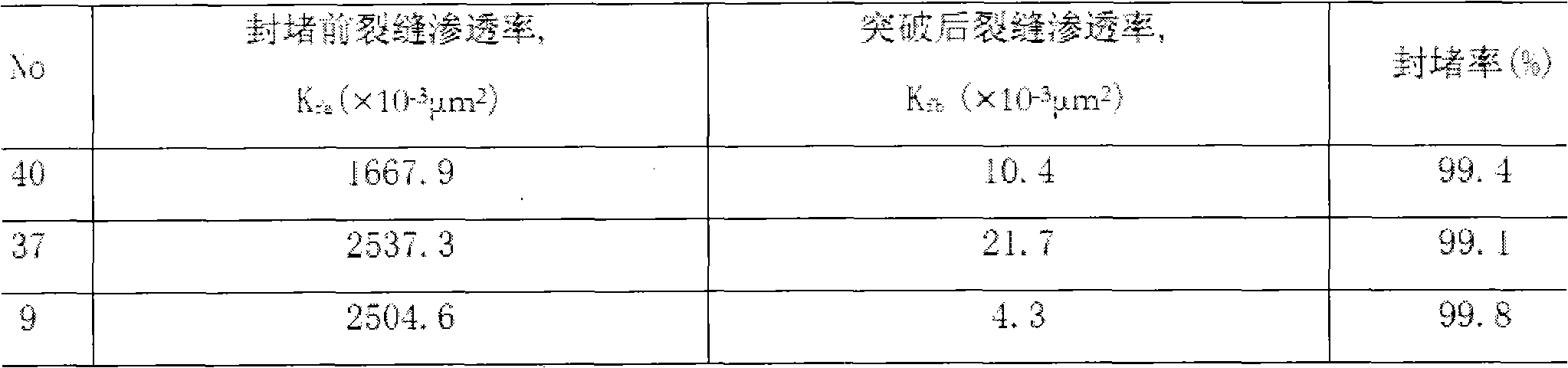

[0046] The results measured by the above method are shown in the table below:

[0047]

[0048] It can be seen from the above table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com