Method for effectively solving problem of nonuniform gap caused by closing folding computer

A folding and computer technology, applied in the field of computers, can solve the problems of occupying the structural space of notebooks, failing to achieve uniform gaps, increasing the cost of notebooks, etc., and achieve the effects of improving appearance and quality, increasing competitiveness, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

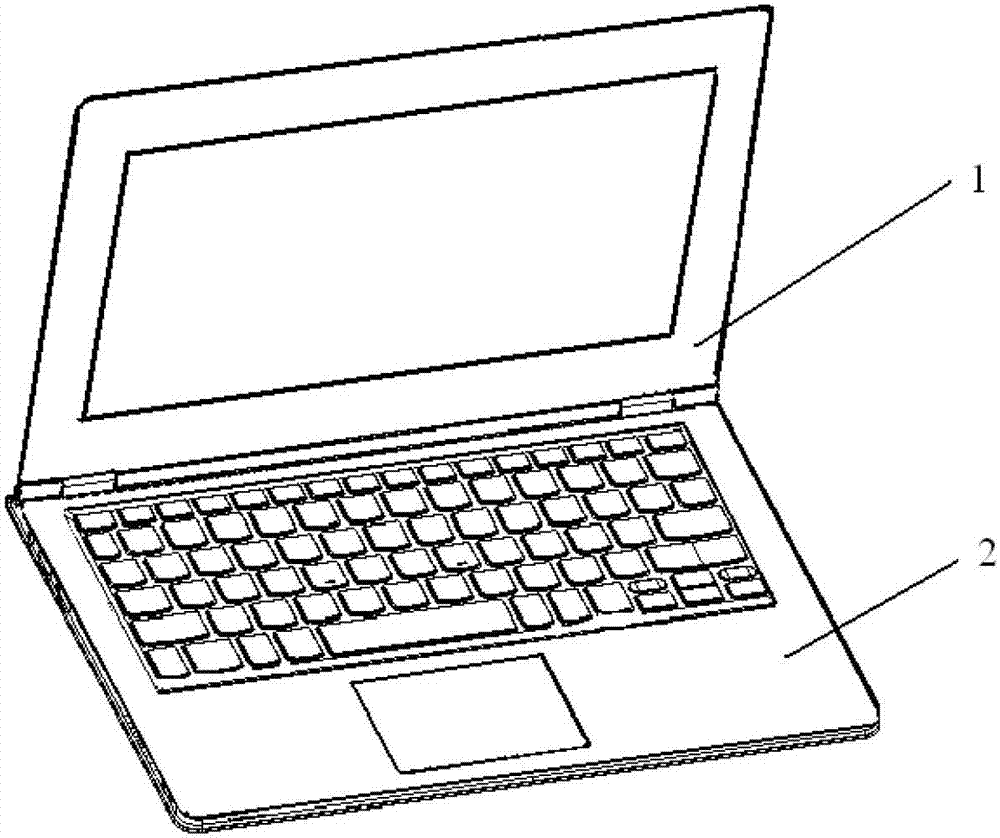

Embodiment 1

[0039] After the permanent magnet ferrite is crushed, it is mixed with ABS engineering plastics in a weight ratio of 1:9, and then plasticized and granulated to obtain magnetic plastic particles (that is, magnetic resin materials, in which the mass content of magnetic materials is 10%); In the conventional process, the magnetic plastic particles prepared above are added to an injection molding machine for injection molding, and a magnetizable and matched notebook computer screen frame 1 and an operation panel 2 (such as figure 1 shown); and then magnetize the screen frame and the operation panel respectively, so that the opposite surface of the screen frame and the operation panel has S pole magnetism and N pole magnetism respectively; the screen frame and operation panel manufactured above and the notebook After assembling other structural parts of the computer (such as display screen, processor, hard disk, memory, keyboard and the screen cover of the shell, base shell, etc.),...

Embodiment 2

[0042] 1. Preparation of magnetic resin materials

[0043] After crushing the permanent magnet ferrite, mix it with ABS engineering plastic in a weight ratio of 3:7, and then add it to the plastic granulator. The mixed material is heated at 220°C in the barrel of the granulator until it is melted and plasticized. After extruding, cooling and automatic pelletizing, magnetic plastic pellets (the mass content of magnetic material is 30%) are obtained;

[0044] 2. Manufacture magnetizable laptop screen frame and operation panel

[0045] Add the magnetic plastic pellets prepared above into the injection device of the injection molding machine. After the magnetic plastic pellets are heated and plasticized in the barrel at 220°C into a fluid state, they are injected into a closed conventional notebook through the nozzle of the barrel under an injection molding pressure of 80MPa. In the computer injection mold, after cooling the mold to a certain temperature and opening the mold, the...

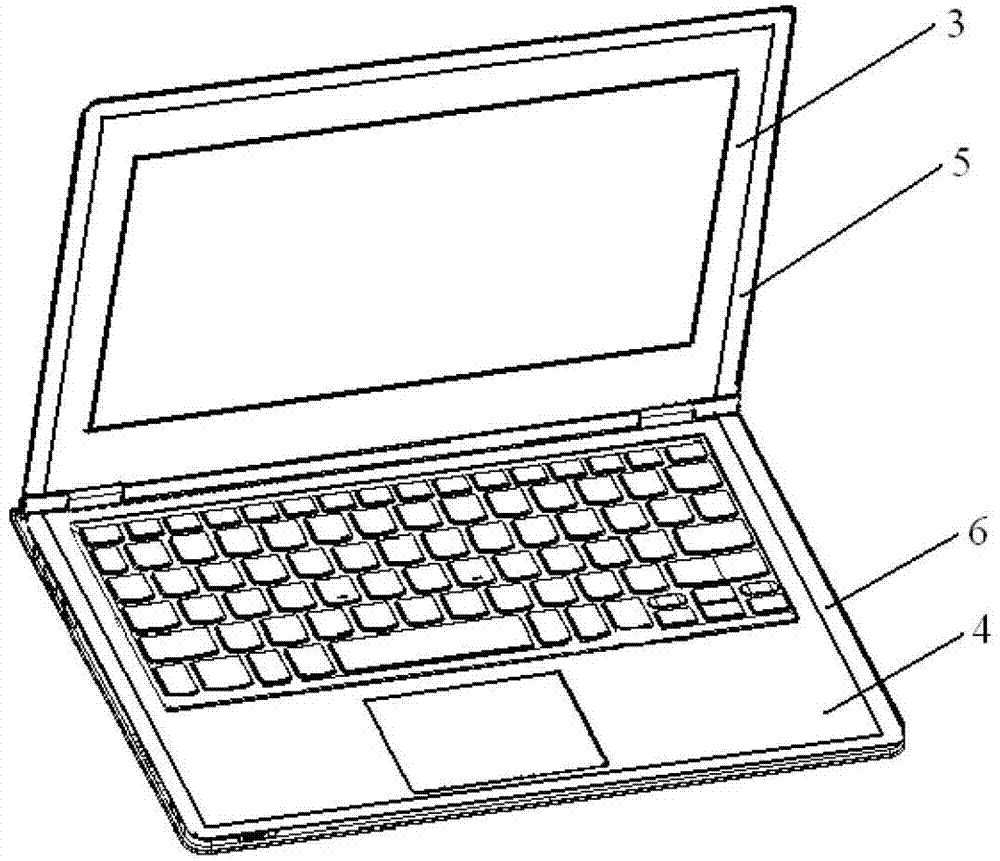

Embodiment 3

[0049] After the NdFeB magnetic material is crushed, it is mixed with nylon 66 (PA66) at a weight ratio of 6:4, and then plasticized and granulated to obtain magnetic plastic granules;

[0050] The PA66 is injection-molded using a conventional process to obtain the screen frame insert 3 and the operation panel insert 4 (such as figure 2 shown); put the above-mentioned screen frame insert 3 and operation panel insert 4 into corresponding insert molding molds respectively, and then use an injection molding machine to inject the magnetic plastic pellets prepared above into the inserts 3 and 4 respectively. In the insert molding mold, the magnetic plastic particles are injected into the outer periphery of the panels of the inserts 3 and 4 during injection. The molten magnetic plastic particles soften the surface of the inserts in contact with them and diffuse into the inserts. After curing and molding, the screen frame Locally magnetizable regions 5, 6 (such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com