Method for producing starting material for sintering

A manufacturing method and technology for raw materials, which are applied in the field of manufacturing raw materials for sintering, can solve problems such as inability to operate, mixed existence of fine powder coke, and inability to obtain sufficient effects, so as to suppress the formation of calcium silicate with weak strength and promote CF. , the effect of shortening the external installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

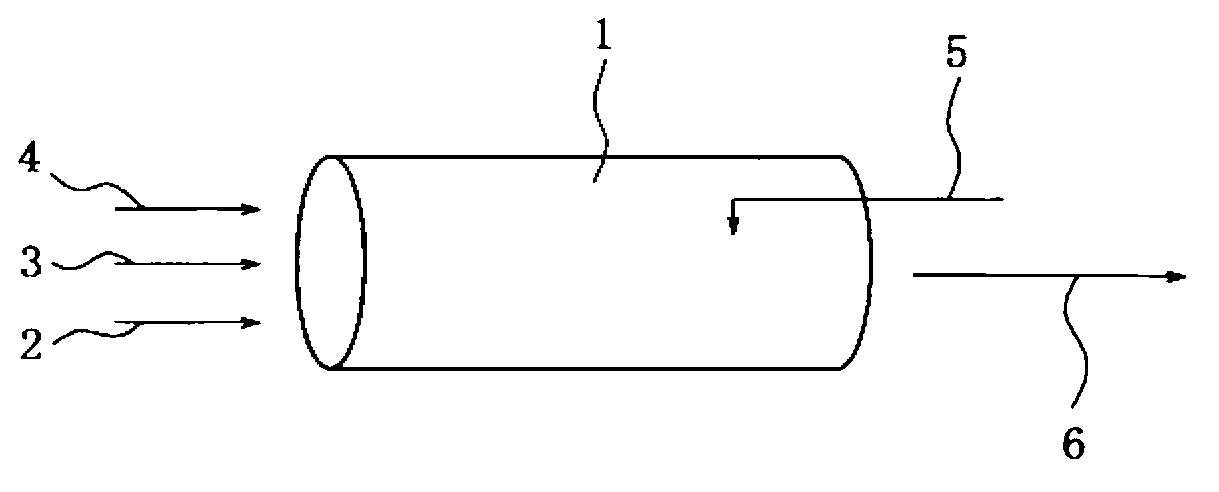

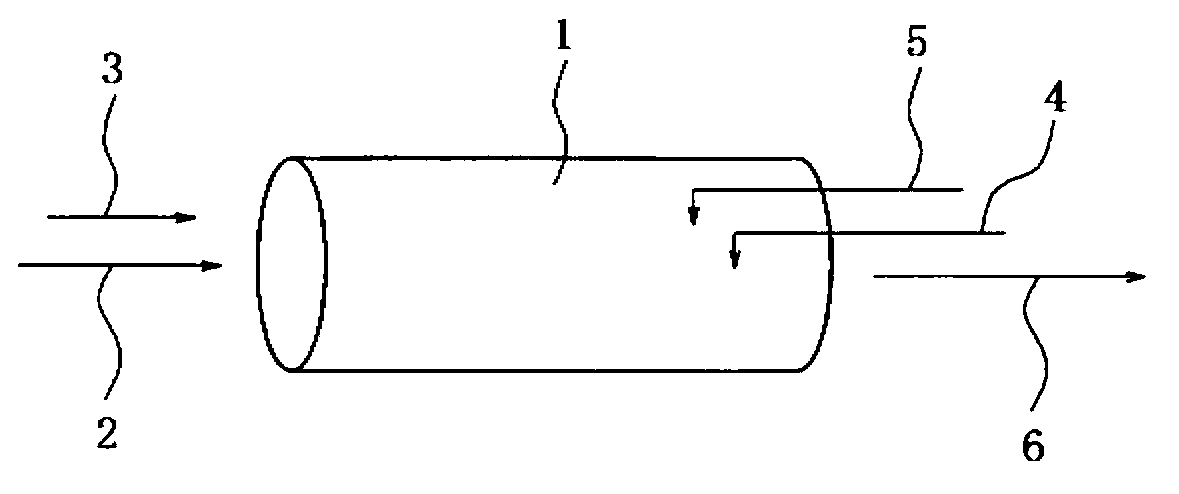

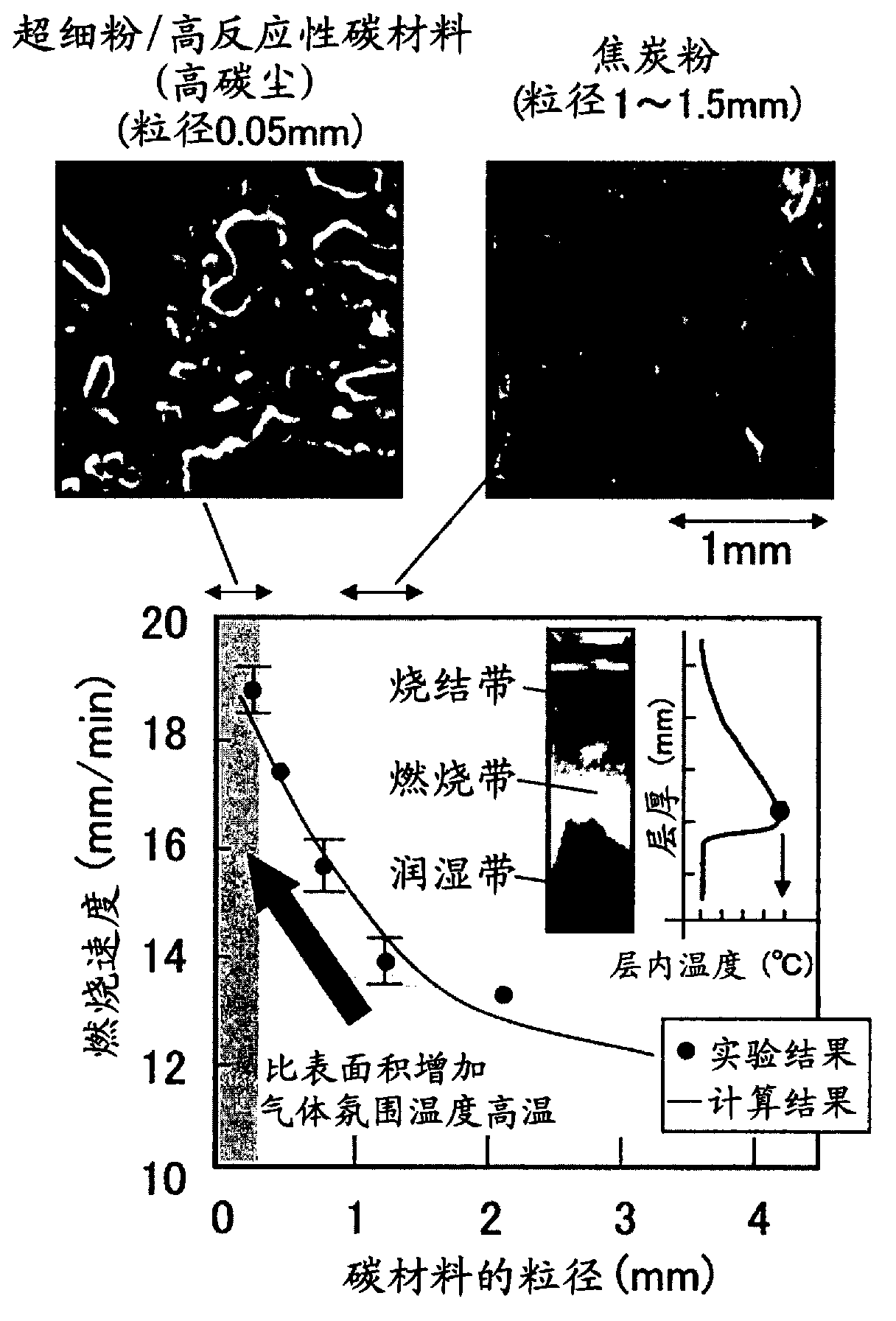

[0142] like figure 2 As shown, iron ore 2 and containing SiO 2 The raw material 3 is charged into the tumble mixer 1 from the inlet for granulation. It should be noted that, as a SiO-containing 2 Raw material 3 used silica or nickel slag. In the tumble mixer 1, iron ore 2 and SiO-containing 2 Raw material 3 was granulated to become quasi-particles, and limestone with an average particle diameter of 0.9 mm was added as limestone-based raw material powder 4 at a position where the residence time of the quasi-particles reached the outlet of the tumble mixer 1 was 40 seconds. 10% by mass, 4% by mass of coke powder with an average particle size of 0.9 mm as the solid fuel raw material powder 5, and 1% by mass of high carbon dust with an average particle size of 50 μm (combined use ratio to the total coke: 20%) . In addition, the specific addition method is to adjust the front end position of the screw conveyor arranged in a manner that can advance and retreat from the dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap