Four-axis optical fiber laser welding device

A fiber laser and welding equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that affect the performance of welding products, welding points are easy to be oxidized, etc., to suppress shielding and scattering, and reduce human errors and manpower requirements, to solve the effect of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

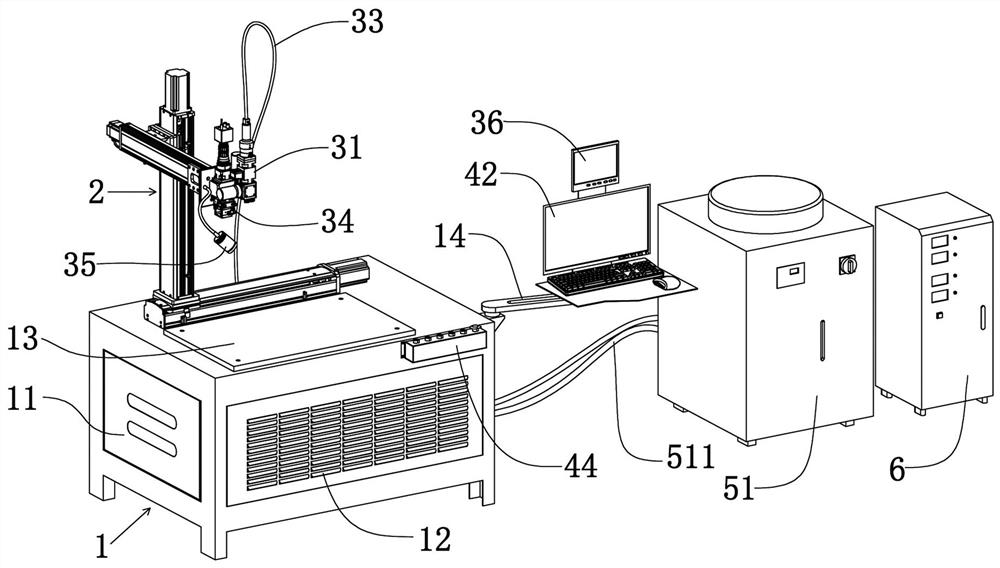

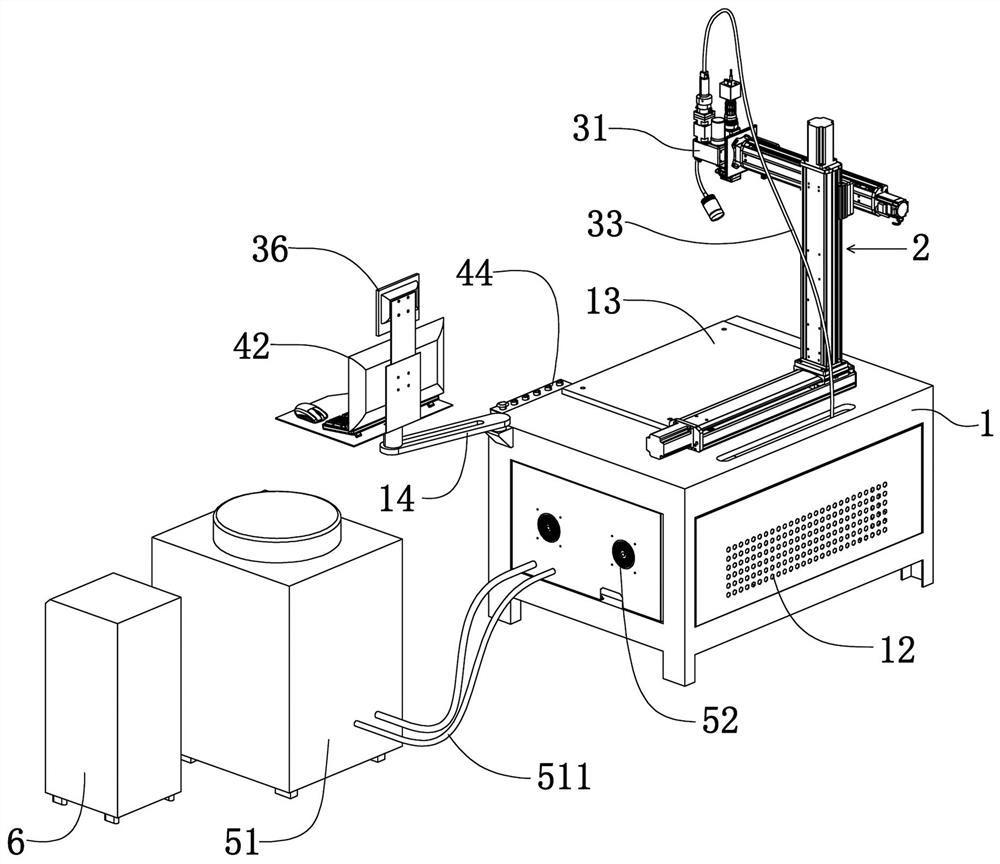

[0041] refer to Figure 1-Figure 6 , the present invention includes a machine platform 1, the machine platform 1 is a metal cabinet structure, the side is provided with an observation window 11 and a heat dissipation window 12, and an industrial computer 41 and a laser generator 32 are provided inside. The top surface of the machine platform 1 is a welding work surface, and a welding table 13 is provided. The present invention also includes a positioning mechanism 2, a welding mechanism, a cooling mechanism, a power supply mechanism 6 and a control mechanism.

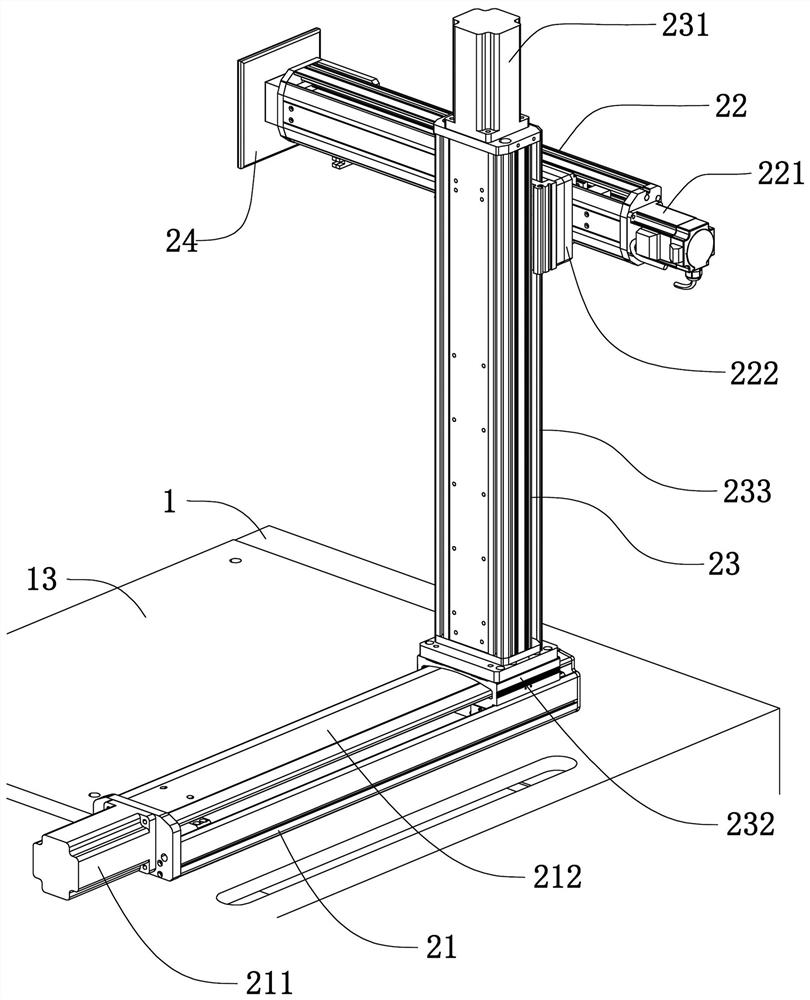

[0042] The positioning mechanism 2 is used for positioning the laser welding head 31, and is arranged on the top surface of the machine table 1, and adopts an XYZ three-axis linkage method. Such as image 3 As shown, the positioning mechanism 2 includes an X-axis device 21 , a Y-axis device 22 , a Z-axis device 23 and a C-axis rotating shaft 24 . The X-axis device 21 is a hollow columnar structure, placed horizontall...

Embodiment 2

[0053] refer to Figure 7 The four-axis fiber laser welding equipment provided in this embodiment has the following improvements on the basis of Embodiment 1: In order to increase the stability of the connection between the Z-axis device 23 and the X-axis device 21, the Z-axis device 23 and the Z-axis slide An L-shaped reinforcing block 234 is added to the joint of the rail 233; in order to prevent the Y-axis device 22 from falling too low to damage the CCD industrial camera 34 or the laser welding head 31, a limit block 235 is provided at the bottom of the Z-axis slide rail 233. Setting the reinforcement block 234 can prevent the positioning mechanism 2 from being deformed or damaged due to the offset of the center of gravity, and can improve the positioning accuracy during welding; setting the limit block 235 can prevent the stroke of the Y-axis device 22 from being too low, and prevent the laser welding head 31 or CCD industrial camera from being too low. 34 is damaged by b...

Embodiment 3

[0055] refer to Figure 8 , The four-axis fiber laser welding equipment provided in this embodiment has the following improvements on the basis of Embodiment 2: a document storage box 16 is provided on the side of the machine 1 for placing documents such as operating procedures and production records.

[0056] The applicant of the present invention requires the operator to record the welding workpiece and the working state of the welding machine during production. The file storage box 16 is provided in this embodiment, and the operator can easily take the production record file to carry out the production process during the production process. Record.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com