Seasoning processing device

A technology for processing devices and condiments, applied in food preparation, application, food science and other directions, can solve the problems of easy spraining of the main shaft, waste, inconvenient maintenance, etc., and achieve the effects of easy maintenance, material saving and production efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following describes the present invention in detail with reference to the drawings and specific embodiments:

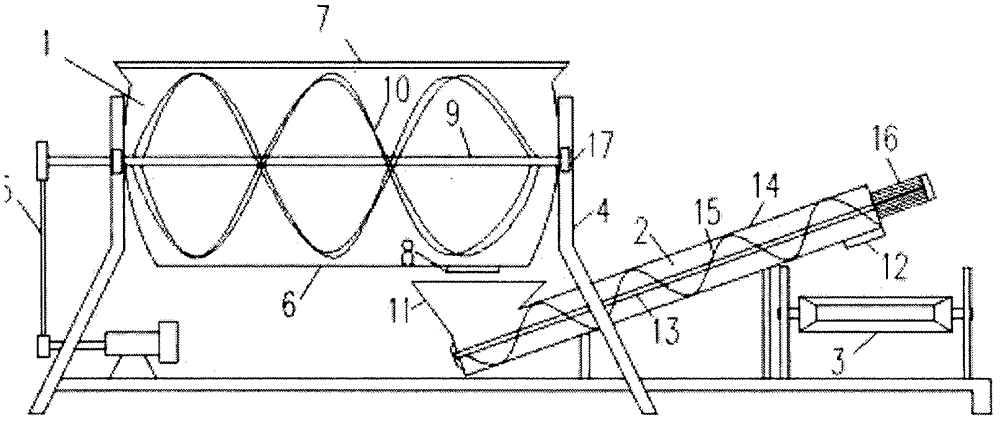

[0011] Control figure 1 The processing device of this embodiment is mainly composed of a mixer 1, a screw feeder 2, and a tipping bucket 3. The three are sequentially fixed on the bracket 4, and the stirring shaft 9 is rotatably supported on the bracket 4 through a bearing 17, and the two directions are opposite The mixing screw blade 10 is welded to the mixing shaft 9 to form a mixing auger. One end of the mixing shaft 9 extends to the outside of the device and is connected to the reduction mechanism 5. The reduction mechanism 5 adopts a chain drive mode with a transmission ratio of 3:1. The upper end of the mixing barrel 6 is for the mixer to enter. The material port 7, the mixer discharge port 8 is set at the bottom of the mixing barrel 6 on the side farther from the speed reduction mechanism 5. The feeding shaft 13 is rotatably supported on the central axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com