Flat cloth bag gas tank pulse type deduster

A pulse type, dust collector technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems affecting the environment and safe operation of equipment, endangering the physical and mental health of operators, and dispersing pollution sources, etc., to achieve the overall structure Optimize the effect of beauty, compact structure, and reduce installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

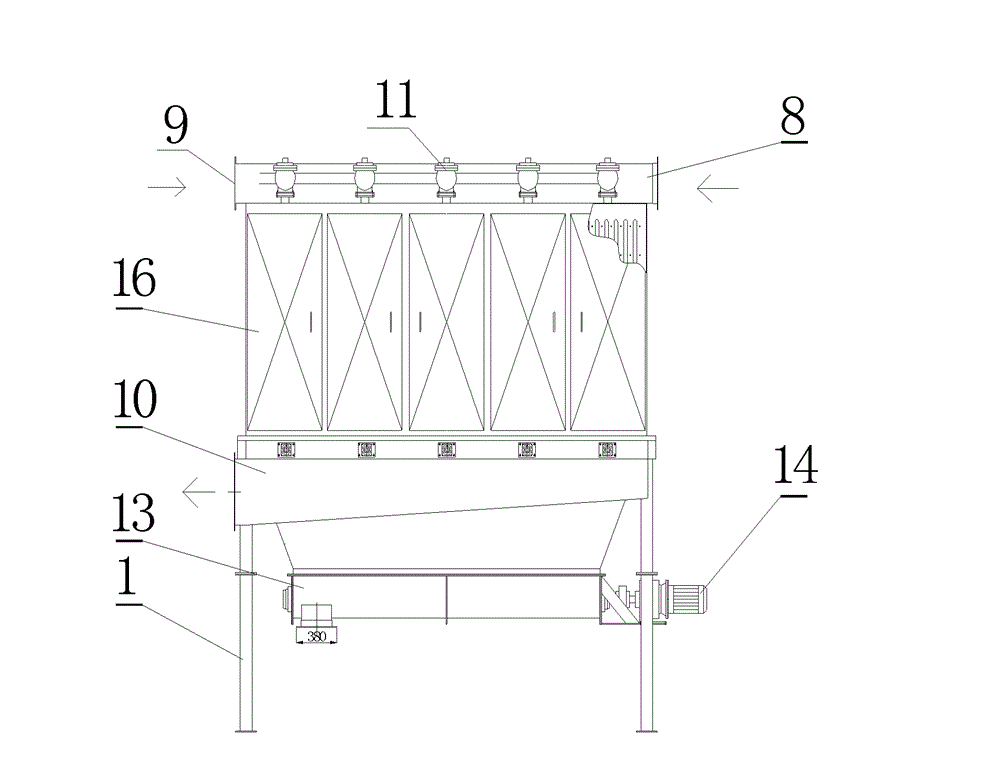

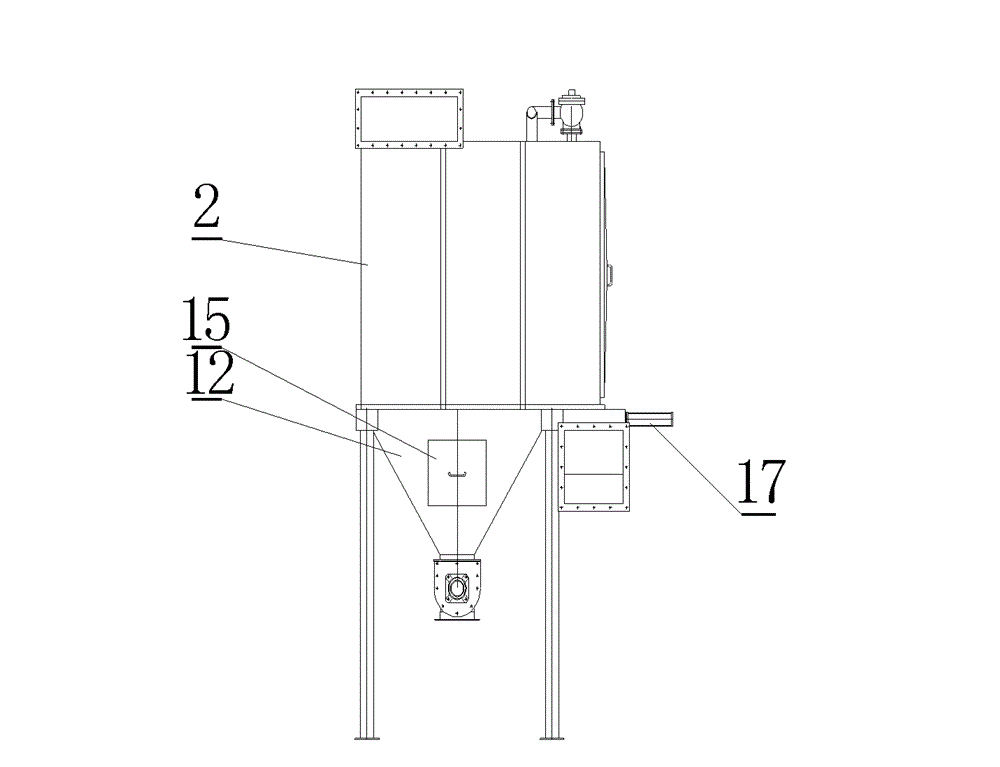

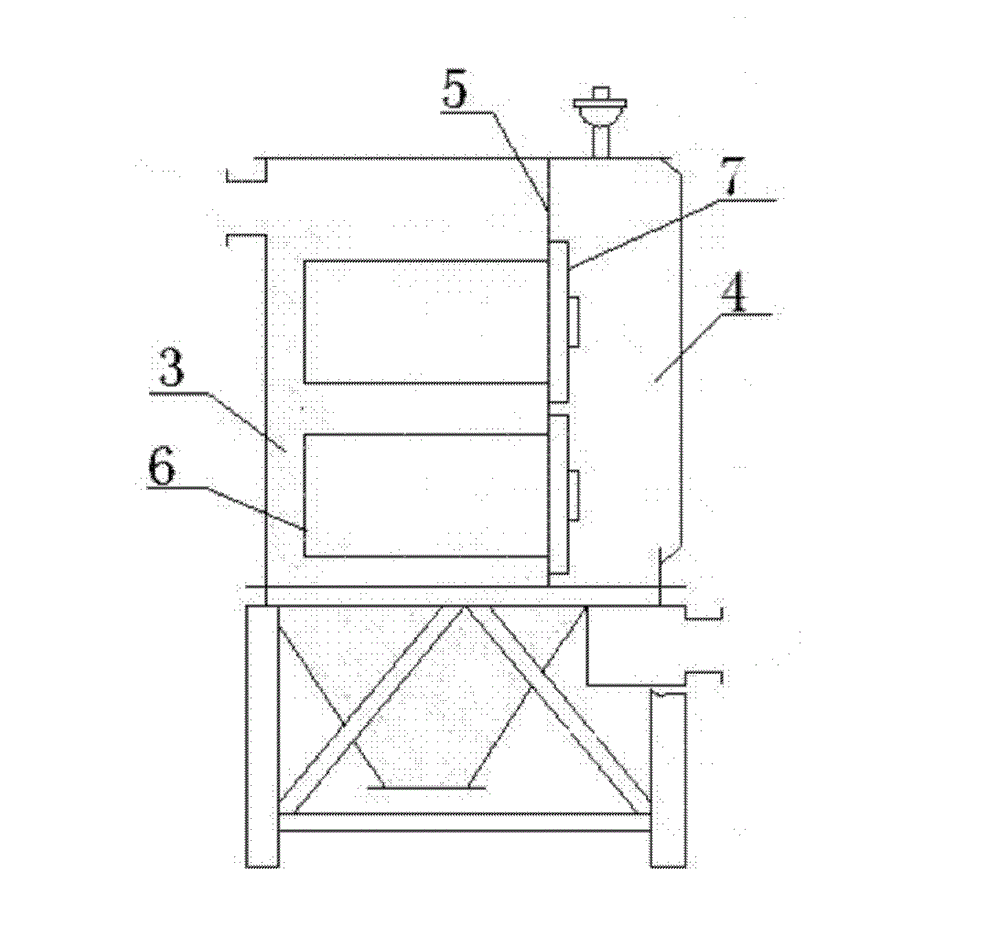

[0021] Such as figure 1 , figure 2 and image 3 As shown, the flat cloth bag air box pulse dust collector of the present invention includes a leg 1 on which an upper box 2 is arranged, and the upper box 2 is divided into a filter chamber 3 and a clean air Chambers 4, separated by flower plates 5 between them, horizontal filter bags 6 are arranged in the filter chamber 3, bag cages 7 are arranged in the horizontal filter bags 6, and air intake is arranged on the upper part of the upper box 2 Channel 8, air inlets 9 are provided at both ends of the air intake channel 8, a clean air outlet groove 10 is provided on the lower side of the upper box 2, and a pulse injection is provided on the upper part of the clean air chamber 4. System 11; an ash hopper 12 is provided between the legs 1, and a screw conveyor 13 is provided below the ash hopper 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com