Impeller

An impeller and blade technology applied to the impeller. It can solve the problems of low work reliability, low product quality, and difficulty in mixing materials evenly, and achieve the effects of good mixing effect, improved work reliability and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

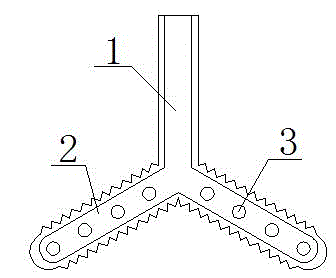

[0011] Such as figure 1 It is a structural schematic diagram of the present invention, an impeller, including a connecting rod 1, a blade 2 and a round hole 3, the connecting rod 1 is fixedly connected to the blade 2, the blade 2 is provided with a round hole 3, and the connecting rod 1 and the blade 2 are in a hollow structure , the blade 2 is serrated on the outside.

[0012] When in use, the lower end of the connecting rod 1 is fixed with a blade 2, both the connecting rod 1 and the blade 2 are hollow, the blade 2 is provided with a circular hole 3, and the outside of the blade 2 is serrated. This kind of impeller has a simple, compact and reasonable structure, convenient and fast assembly, reliable connection, so that the materials can be mixed evenly, and the materials can complete the reaction in a very short time of contact, with high working efficiency and good stirring effect, which greatly improves the efficiency of the stirring device. Work reliability, easy to use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com