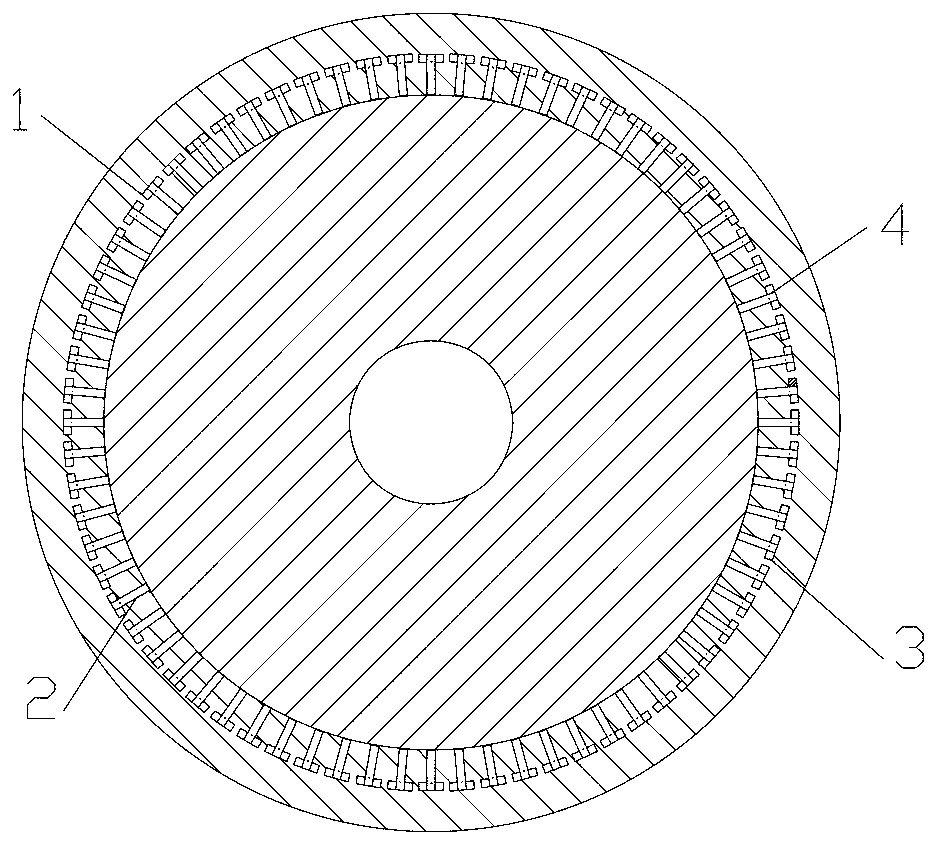

Structure of copper bush of amorphous crystallizer

A crystallizer copper and amorphous technology, which is applied in the field of amorphous crystallizer copper sleeve structure, can solve the problems of excessive cooling capacity and insufficient cooling uniformity of the amorphous crystallizer, and achieves the advantages of reducing process requirements and improving material yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

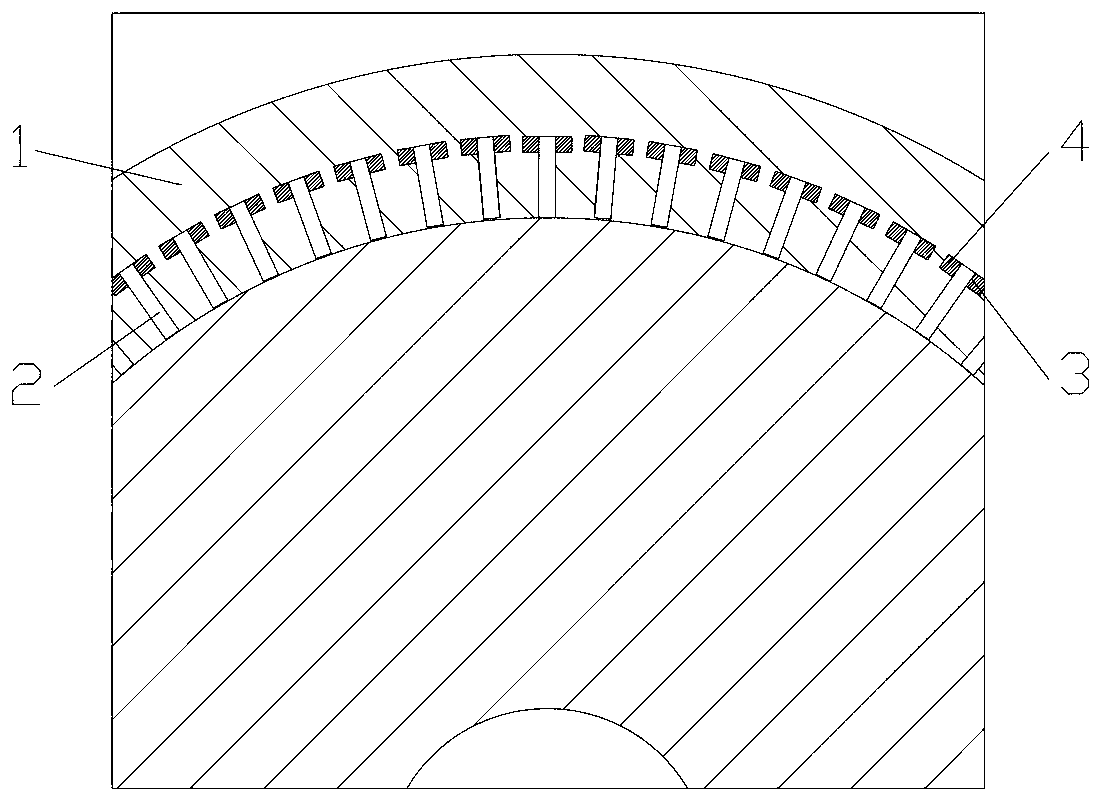

Embodiment 1

[0024] Embodiment 1. After the crystallizer is installed, the effective thickness of the copper sleeve 1 is greater than 12 mm, and all the adjusting copper strips 4 are on the mold copper sleeve 1 at this time. After commissioning and commissioning, the crystallizer can spray qualified strips: the strip thickness is 28μm, the width is 142mm, the lateral thickness deviation is not more than 2μm, the lamination coefficient is not less than 86, and the iron loss is less than 0.19W / kg.

Embodiment 2

[0025] Embodiment 2. When the effective thickness of the mold copper sleeve 1 is less than 12mm, the lamination coefficient is unstable, and sometimes the lamination coefficient is less than 82. At the same time, the band begins to appear broken bands and ruffles. At this time , remove the adjusting copper bar 4 inlaid on the side of each rectangular slot 3 along the same rotation direction, that is, each rectangular slot 3 uses one adjusting copper bar 4, that is, remove half of the adjusting copper bar 4, the above-mentioned bad phenomenon disappears, and the The lateral thickness deviation of the material is mostly below 2 μm.

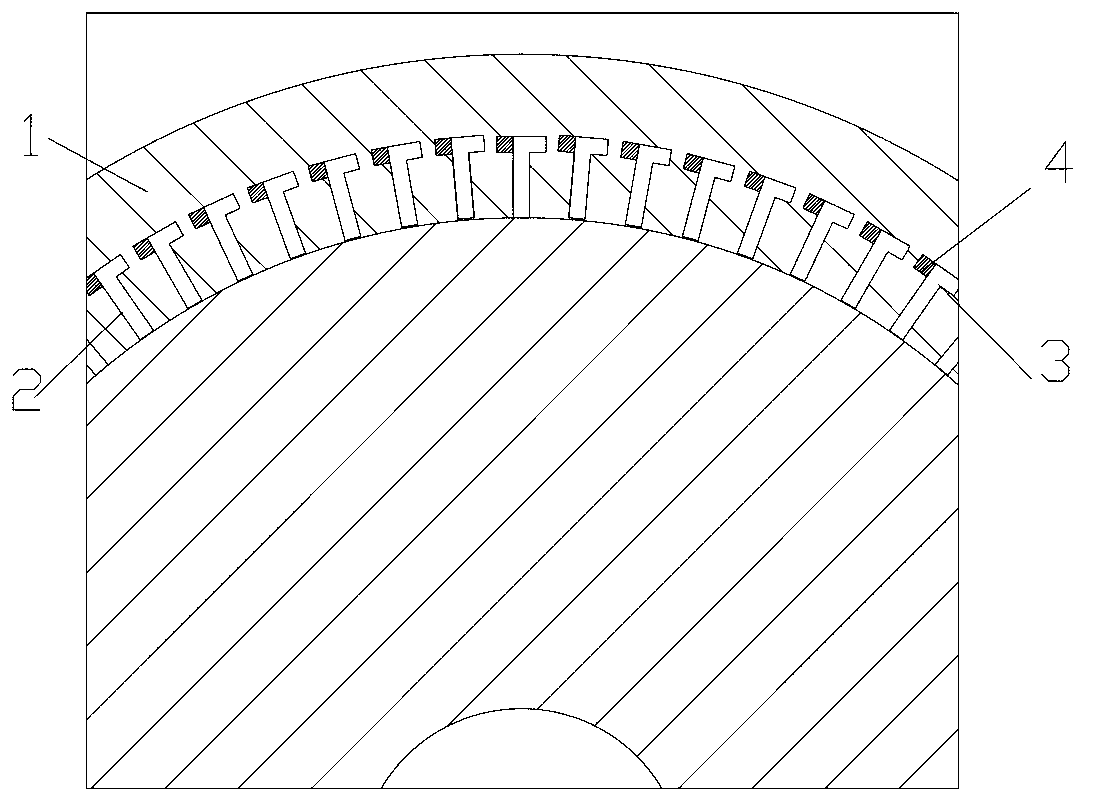

Embodiment 3

[0026] Embodiment 3. When the thickness of the mold copper sheath 1 reaches 5.5 mm, the band breakage is serious and it is difficult to produce stably. At this time, all the adjusting copper strips 4 are removed, and the amount of water is appropriately reduced, so that the broken belt phenomenon disappears, and stable production can be performed again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| With thick | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

| Iron loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com