Shaft gear composite processing machine tool

A composite processing and gear technology, applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of low degree of automation, low gear processing efficiency, waste of resources, etc., to reduce production costs, save conversion time, The effect of guaranteed machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

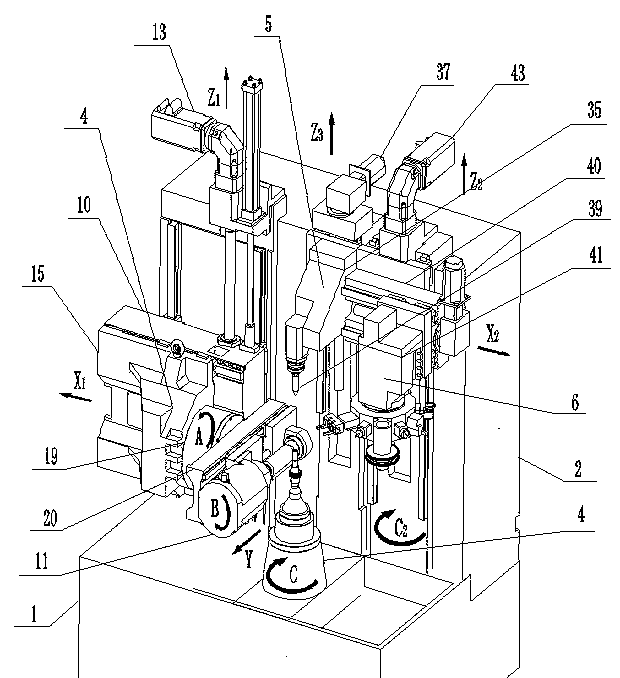

[0031] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

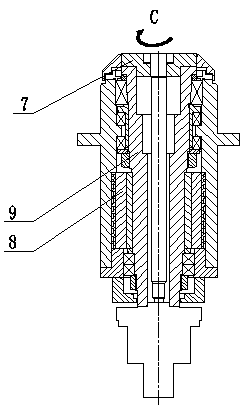

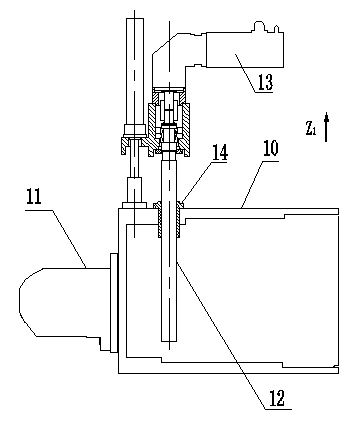

[0032] As shown in the figure, a shaft gear compound processing machine tool of the present invention includes a bed 1, a column 2 fixed on the bed 1, a rotary table 3, a hob feed mechanism 4, and a support frame feed mechanism 5 and the rotary turret feed mechanism 6; the rotary table 3 is fixed on the top surface of the bed 1; The column 2 is close to the side of the rotary table 3 and is slidably fitted with the column 2 in the vertical direction. Place the workpiece on the rotary table 3, the support frame feeding mechanism 5 slides up and down according to the height of the workpiece to adjust and fix the workpiece to rotate on the rotary table 3, the hob feeding mechanism 4, and the rotary turret feeding mechanism 6 According to the different processing positions of the workpiece, it slides up and down, and the workpiece is processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com