Slide block synchronizing mechanism for four cylinder driving hydraulic machine

A technology of synchronous mechanism and hydraulic press, applied in the direction of presses, manufacturing tools, etc., can solve problems such as synchronous coordination, product performance up to standard, pressure relief, etc., and achieve the effects of compact and reasonable structure, elimination of synchronous errors, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

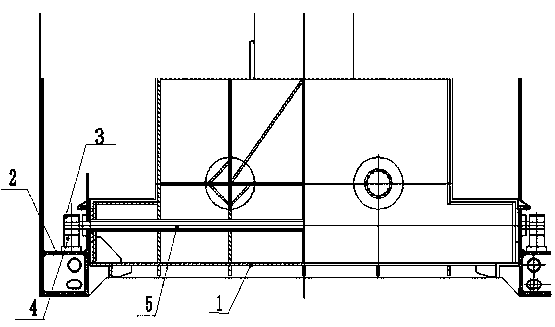

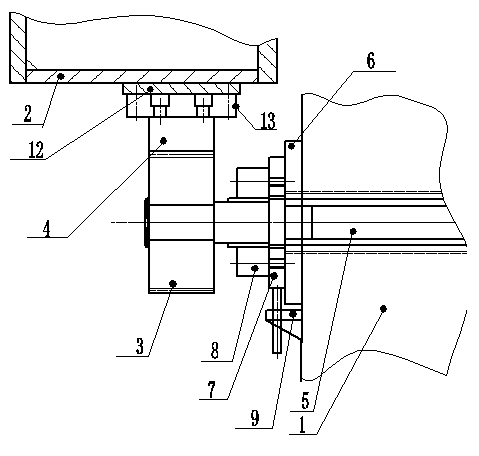

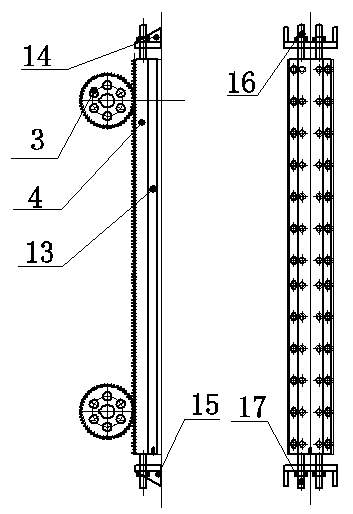

[0023] The present invention will be further described below in conjunction with the drawings.

[0024] Combine figure 1 , 2 , 3, 4, 5, 6 and 7, the present invention includes a slider 1 and a fuselage column 2; on the slider 1, four corners are provided with gears 3, and the fuselage four columns 2 are provided with The rack 4 matched with the four gears forms a gear and rack synchronization mechanism. The four gears 3 are arranged at the two ends of two positioning shafts 5 passing through the inside of the slider; and the two positioning shafts pass through the inner gear fixing pad 6 fixed on both sides 1 of the slider; the inner gear fixing pad 6 is provided with threaded holes; outside the fixed backing plate 6 is also provided with a gear movable backing plate 7; the two positioning shafts are supported by an outer spherical bearing 8 with a square seat installed on the side of the gear movable backing plate 7 The gear movable backing plate 7 is provided with a waist-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com