Oil and gas suspension system and engineering vehicles

A technology of oil and gas suspension and left suspension, which is applied to vehicle components, fluid pressure actuation system components, suspensions, etc., can solve the problem that the relative position of the cylinder and the piston rod cannot be monitored in real time, and achieves continuous vehicle height adjustment, The effect of fast and sufficient oil replenishment and precise control of the body posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

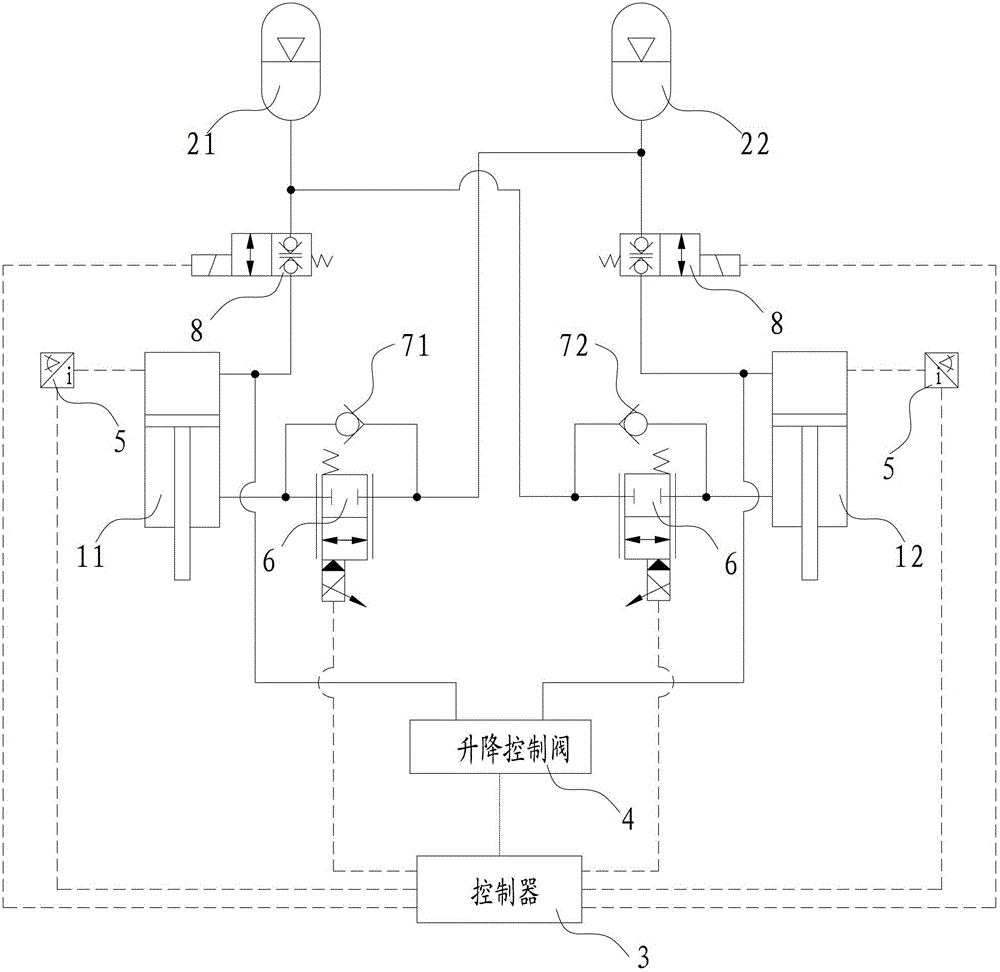

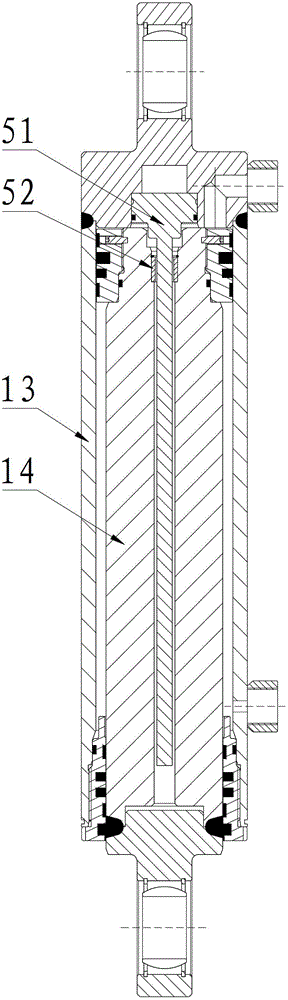

[0032] figure 1 and figure 2 That is the relevant drawings of this embodiment, as shown in the figure, the oil-pneumatic suspension system described in this embodiment includes a controller 3, a lifting control valve 4, a suspension cylinder, an accumulator, two position sensors 5, two Directional control valve 8, left damping device, right damping device, left one-way valve 71 and right one-way valve 72. Wherein, the suspension oil cylinder includes two left suspension oil cylinders 11 and 12 right suspension cylinders, and the accumulator includes two left accumulators 21 and 22 right accumulators, and the directional control valve 8 is a normally closed valve controlled by the controller 3. Two-position two-way solenoid valve. The left damping device and the right damping device are two electric proportional valves 6 controlled by the controller 3 . The lifting control valve 4 is an electromagnetic reversing valve controlled by the controller 3. The lifting control valv...

Embodiment 2

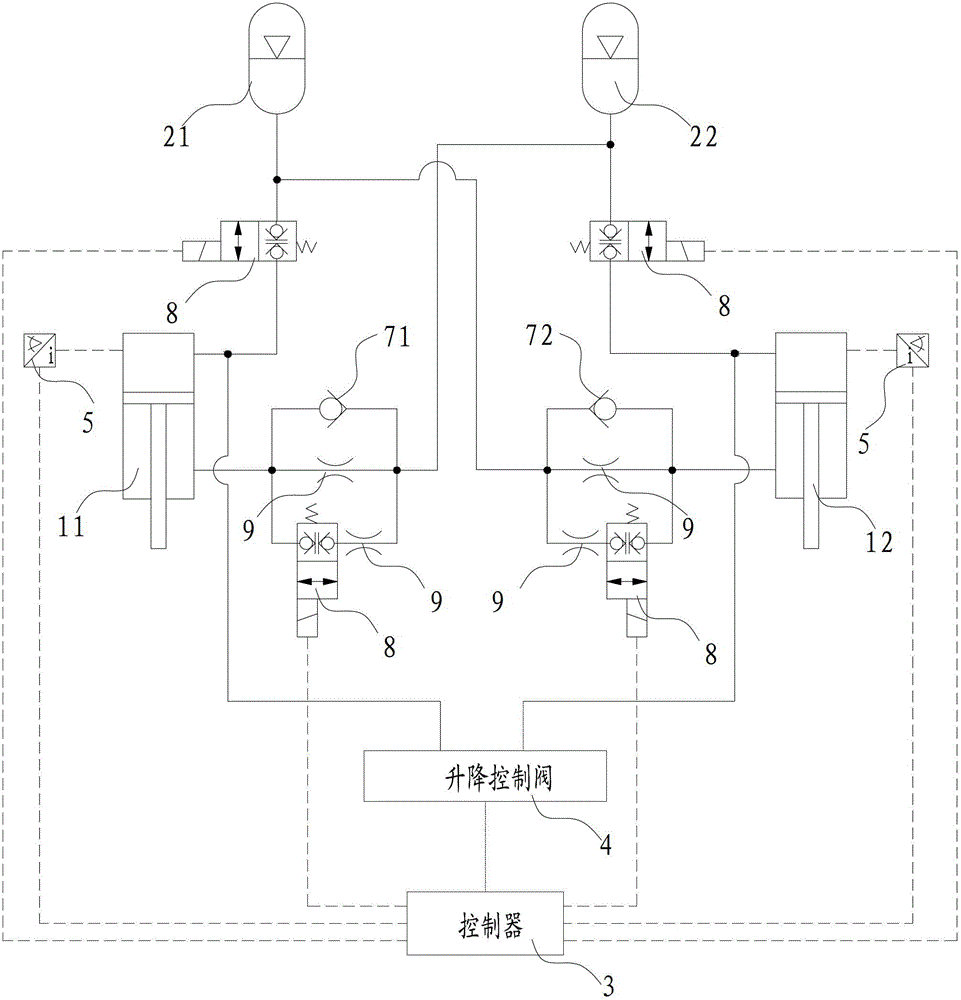

[0039] image 3 That is the relevant drawings of this embodiment, as shown in the figure, except for the damping device, the rest of the structure of this embodiment is completely consistent with that of Embodiment 1. The left damping device and the right damping device in this embodiment are both multi-stage damping switching valves, and the multi-stage damping switching valve includes two mutually parallel damping holes 9 and a directional control valve 8, and this directional control valve 8 is connected to one of them. The damping holes 9 are connected in series. The directional control valve 8 is also a two-position two-way solenoid valve controlled by the controller 3 , and the damping can be adjusted stepwise by controlling the on-off of the directional control valve 8 .

[0040] As other modified implementations of this embodiment, the damping device can be more than two damping holes 9 connected in parallel with each other, and there can also be multiple directional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com