Mechanical carrying device

A technology for mechanical handling and lead screw nuts, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of poor control of manipulator operation accuracy, high power requirements, slow activation and operation, etc., to achieve labor-saving handling and large transmission force , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

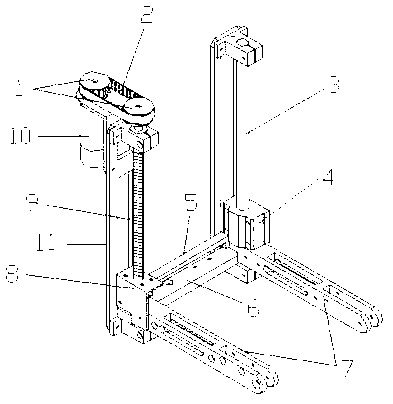

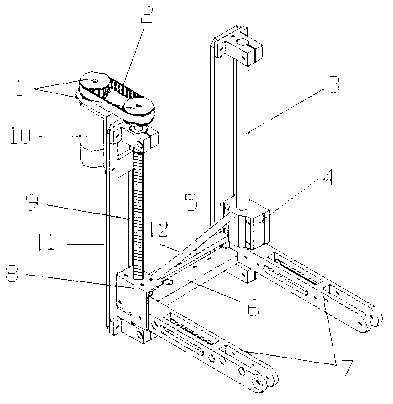

[0023] combined with figure 1 As shown, a kind of mechanical handling device comprises a support 11, a motor 10 installed on the support 11, a lead screw 9 with a lead screw nut 8 and a polished rod 3 with a slider 4 are also installed on the support 11, Screw mandrel 9 is parallel with polished rod 3, is connected by linkage rod 5 between described screw nut 8 and slide block 4, and described motor 10 and leading screw 9 are respectively provided with synchronous pulley 1 (comprising motor synchronous pulley and wire Bar synchronous pulley), synchronous belt 2 drives and connects 2 synchronous pulleys 1; Support bar 6 and arm 7 are installed on described leading screw nut 8 and slide block 4, and described arm 7 and screw mandrel 9 are perpendicular to each other.

[0024] When working, the motor 10 drives the synchronous pulley of the motor, drives the synchronous pulley of the screw rod through the transmission of the timing belt 2, and then drives the screw rod 9 to rotate...

Embodiment 2

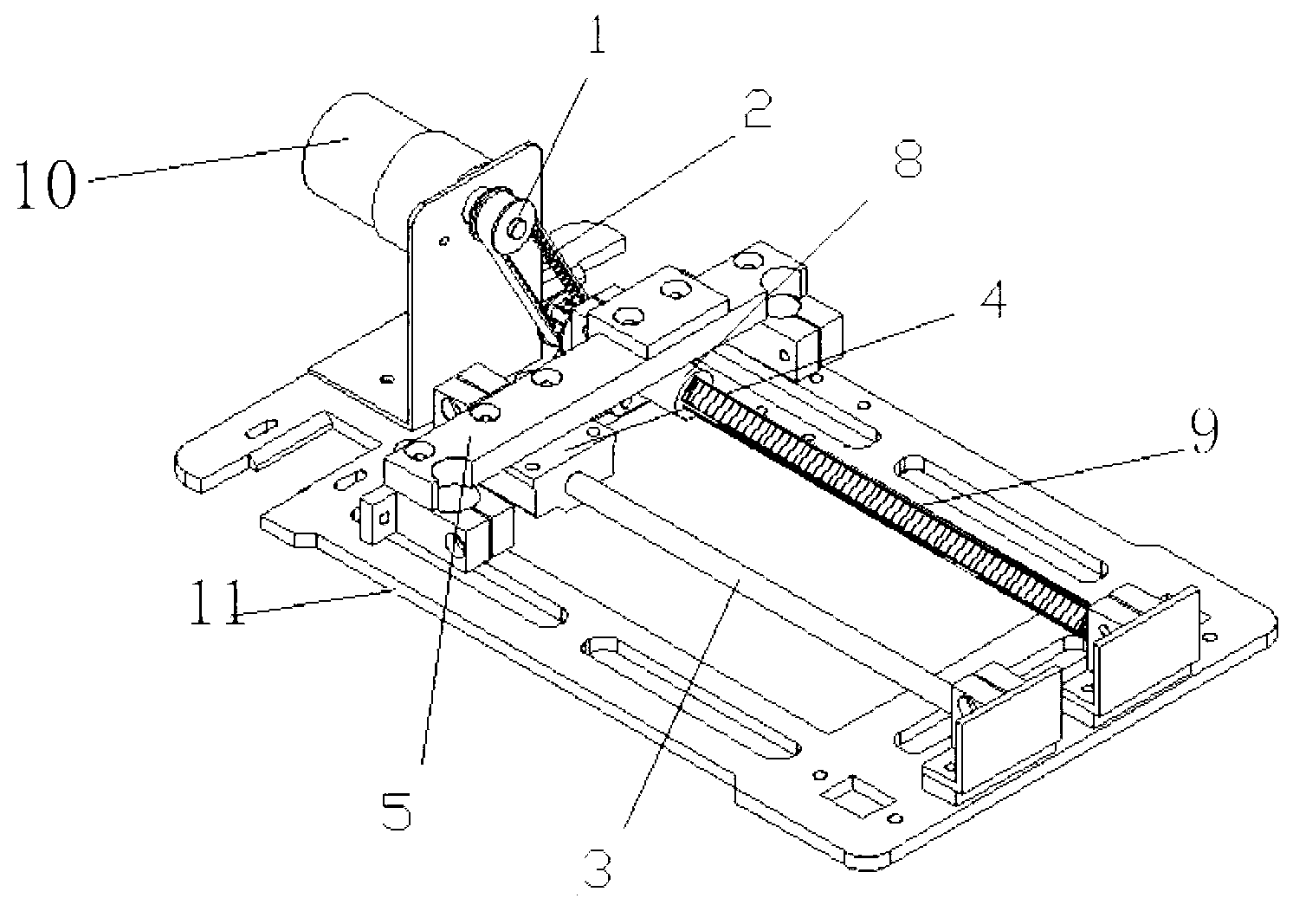

[0029] combined with image 3 As shown, a kind of mechanical handling device comprises a support 11, a motor 10 installed on the support 11, a lead screw 9 with a lead screw nut 8 and a polished rod 3 with a slider 4 are also installed on the support 11, The screw nut 8 and the slide block 4 are connected by a linkage rod 5, and the motor 10 and the leading screw 9 are respectively provided with a synchronous pulley 1, and the synchronous belt 2 is driven to connect two synchronous pulleys 1; the leading screw The nut 8 and the slide block 4 can be provided with a support rod (the linkage rod 5 on the screw nut 8 and the slide block 4 can also play the role of a support rod, and the linkage rod 5 has not only played a role of fixed installation, but also can bear cargo).

[0030] Preferably, a diagonal brace with an included angle of 60-80° to the screw rod is further provided between the lead screw nut and the slider, and the length of the corresponding slider along the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com