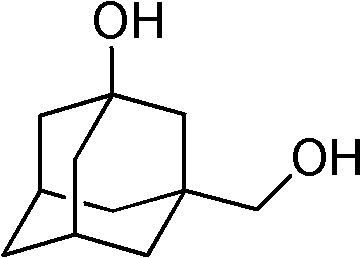

The synthetic method of 1-hydroxyl-3-hydroxymethyladamantane

A technology of hydroxymethyladamantane and synthesis method, which is applied in the field of synthesis of 1-hydroxy-3-hydroxymethyladamantane, can solve the problems of product purification increase, difficulty, low conversion rate, etc., and achieve reduction of reaction impurities and by-products Reaction, improve industrial production, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steps of the synthetic method of 1-hydroxy-3-hydroxymethyladamantane in the present invention are as follows:

[0023] 1) First prepare 2% potassium hydroxide aqueous solution, add 40g potassium permanganate to the potassium hydroxide aqueous solution at room temperature, then add 1-adamantanecarboxylic acid in batches, the added amount is 40g (0.22mol) ), slowly warming the above reaction solution to 70-85°C until the reaction solution turns brown, then cooling the reaction solution to 20-30°C; adding concentrated hydrochloric acid at room temperature, and adjusting the reaction solution to be strongly acidic. The solid sodium bisulfite was then added until the solid manganese dioxide reaction was complete. The white precipitate was collected by filtration, washed three times with water, and dried in vacuo to obtain 36.2 g of crude 1-hydroxy-3-adamantanecarboxylic acid with a yield of 83.1%. m.p.198-199", the crude product was recrystallized from acetone:water (9:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com