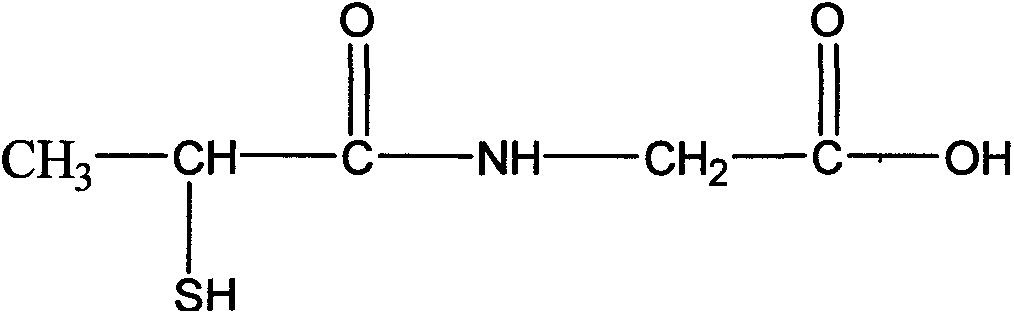

Refining method of tiopronin

A tiopronin, refining and purification technology, applied in the field of medicine and chemical industry, can solve the problems of low product purity, long production cycle, difficult process control, etc., and achieve the effect of simple refining process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 80g of crude product tiopronin (purity 96.8%) in a 1000ml four-neck flask, add 240ml of ethyl acetate and 40ml of acetone, heat up and reflux for 0.5 hours, stir and cool down to room temperature 30°C, keep warm for 0.5 hours, continue to cool down to 0- 5°C, stir and keep warm for 2 hours, filter, rinse the wet product with a small amount of n-hexane at 0-5°C, dry the sample in vacuum at 45°C for 6-8 hours, and obtain 65.6g of refined sample, yield 82%, purity 98.8% , the single impurity content is in line with the State Food and Drug Administration Drug Trial Standard (YBH 12042005).

Embodiment 2

[0029] Put 80g of crude product tiopronin (purity 96.8%) in a 1000ml four-neck flask, add 320ml of ethyl acetate and 40ml of acetone, heat up and reflux for 2 hours, stir and cool down to room temperature 30°C, keep warm for 1 hour, continue to cool down to 0- 5°C, stir and keep warm for 5 hours, filter, rinse the wet product with a small amount of n-hexane at 0-5°C, dry the sample in vacuum at 45°C for 6-8 hours, and obtain 60.3g of refined sample, yield 75.4%, purity 99.1% , the single impurity content is in line with the State Food and Drug Administration Drug Trial Standard (YBH 12042005).

Embodiment 3

[0031] Put 80g of crude product tiopronin (purity 96.8%) in a 1000ml four-neck flask, add 240ml of ethyl acetate and 80ml of acetone, heat up and reflux for 1 hour, stir and cool down to room temperature 30°C, keep warm for 2 hours, continue to cool down to 0- 5°C, stir and keep warm for 8 hours, filter, rinse the wet product with a small amount of n-hexane at 0-5°C, dry the sample in vacuum at 45°C for 6-8 hours, and obtain 63.8g of refined sample, yield 79.7%, purity 99.3% , the single impurity content is in line with the State Food and Drug Administration Drug Trial Standard (YBH 12042005).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com