Hydrotreating method for heavy residual oil

A heavy residual oil and hydrotreating technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., to achieve the effect of ensuring long-term stable use, reducing possibility, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The medium-sized residual oil hydrotreating test device of the Sinopec Petrochemical Research Institute was used to hydrotreat the light sandy slag A (see Table 1 for properties).

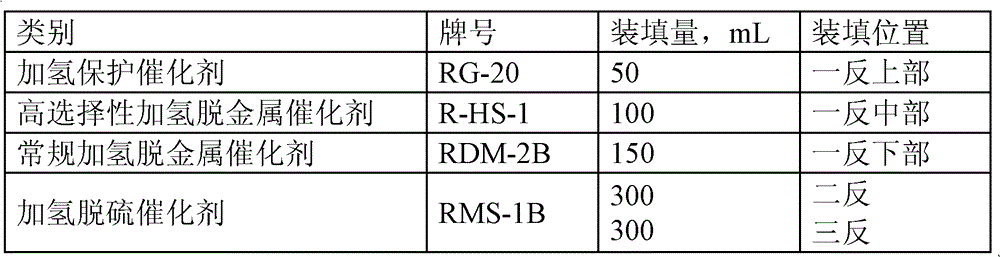

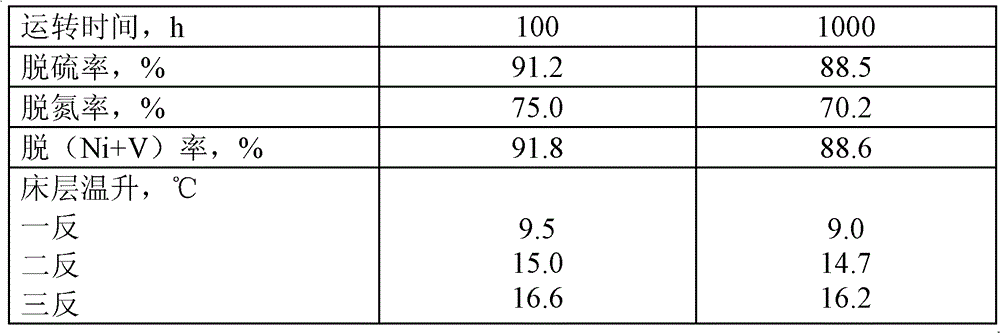

[0032] Three reactors are used, and the catalyst loading capacity of each reactor is 300mL. The catalyst loading conditions are shown in Table 2 (one reverse is the abbreviation of the first reactor, and the others are similar), wherein the high-selectivity hydrodemetallization catalyst used The properties of R-HS-1 are shown in Table 3. Hydrotreating conditions include: reaction temperature 380°C, hydrogen partial pressure 14.0MPa, hydrogen-oil volume ratio 700Nm 3 / m 3 , the volumetric space velocity is 0.2h -1 . Carry out the tests of 100h and 1000h respectively, and detect the properties of the product during 100h and 1000h, the results are shown in Table 4.

[0033] Table 1

[0034]

Light sandy slag A

Density at 20°C, kg / m 3

995.5

Viscosity at 100...

Embodiment 2

[0048] According to the method of Example 1, the light sandy slag A was subjected to hydrogenation treatment. The difference is that the catalyst loading conditions are shown in Table 7, and the properties of the high-selectivity hydrodemetallation catalyst R-HS-2 used are shown in Table 3. Hydrotreating conditions include: reaction temperature 330°C, hydrogen partial pressure 18.0MPa, hydrogen-oil volume ratio 1500Nm 3 / m 3 , the volumetric space velocity is 0.5h -1 . Carry out the tests of 100h and 1000h respectively, and detect the properties of the product at 100h and 1000h, the results are shown in Table 8.

[0049] Table 7

[0050]

[0051] Table 8

[0052]

Embodiment 3

[0054] According to the method of Example 1, the light sand and normal slag A was hydrotreated. The difference is that the catalyst loading conditions are shown in Table 9, and the properties of the highly selective hydrodemetallation catalyst R-HS-3 used are shown in Table 3. Hydrotreating conditions include: reaction temperature 400°C, hydrogen partial pressure 12.0MPa, hydrogen-oil volume ratio 1200Nm 3 / m 3 , the volume space velocity is 0.8h -1 . Carry out the tests of 100h and 1000h respectively, and detect the properties of the product during 100h and 1000h, the results are shown in Table 10.

[0055] Table 9

[0056]

[0057] Table 10

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com